Because ‘we’ll fix it when it breaks’ isn’t a growth strategy

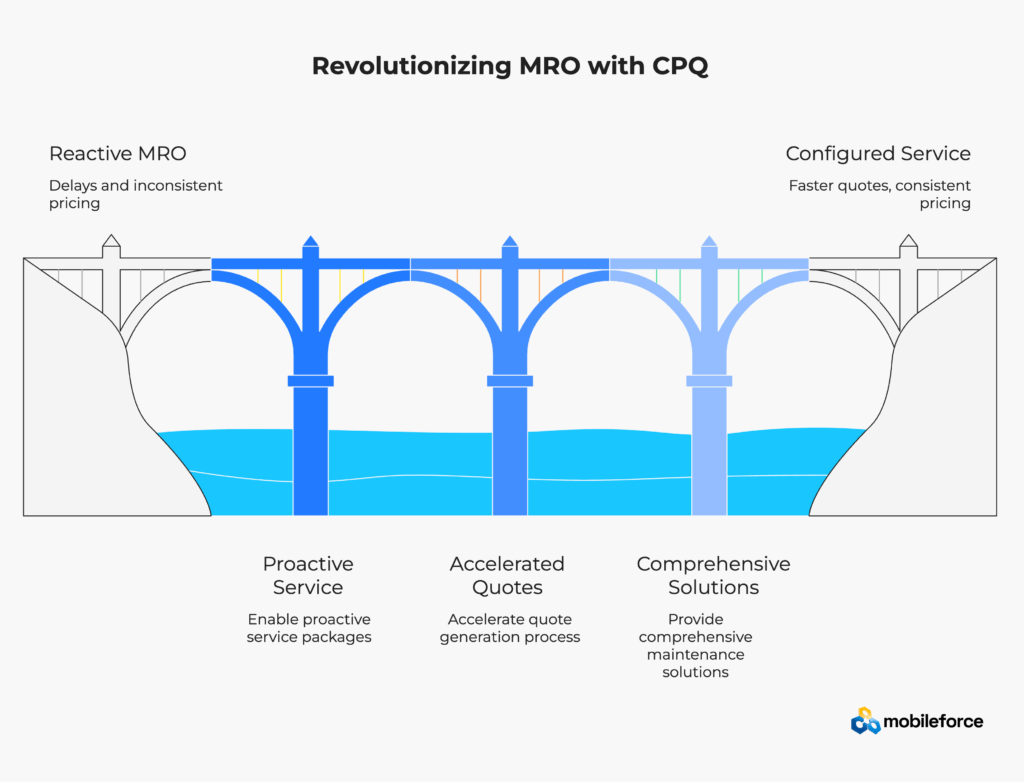

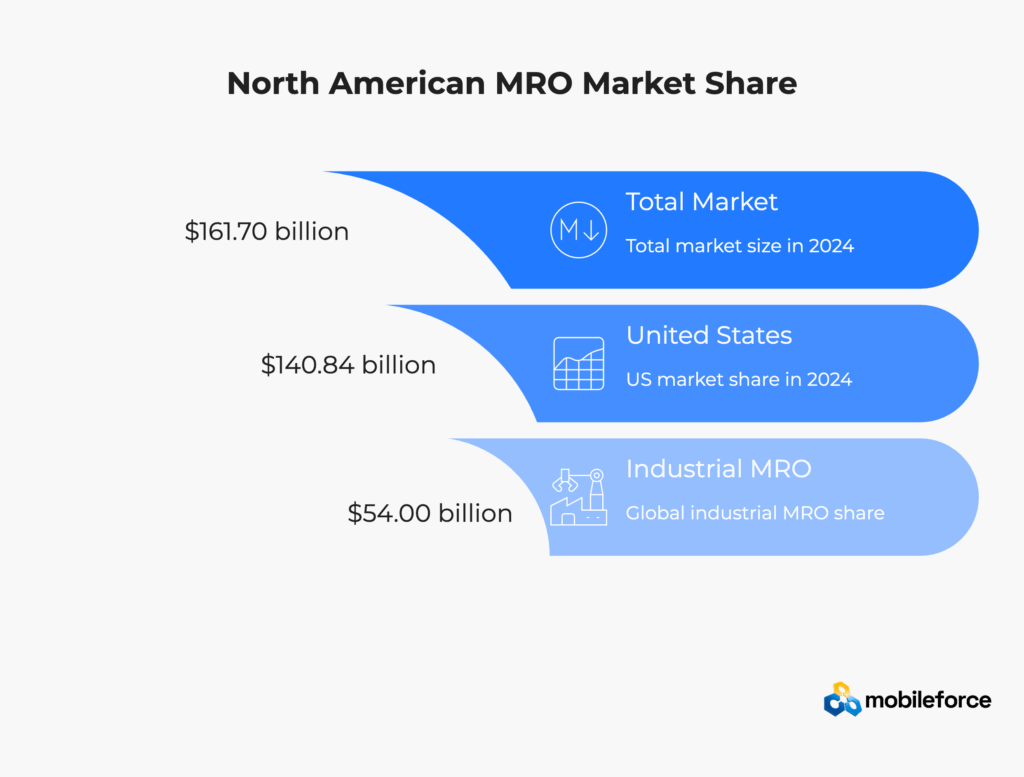

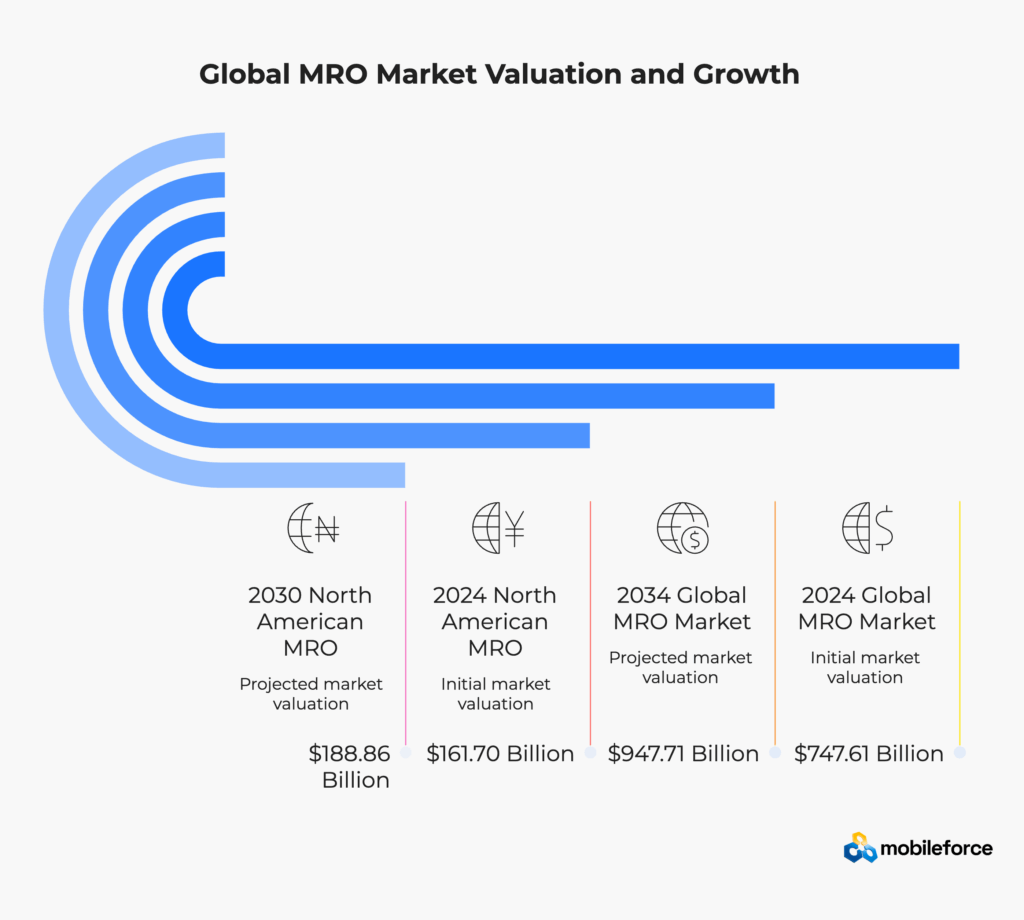

Heavy machinery operators invest billions annually in maintenance, repair, and overhaul (MRO) activities, yet many still depend on reactive, manual quoting processes that generate delays, pricing inconsistencies, and prolonged equipment downtime. Advanced Configure-Price-Quote (CPQ) platforms are revolutionizing MRO operations by enabling proactive service packages, accelerated quote generation, and comprehensive maintenance solutions. With the North American MRO market reaching $161.70 billion in 2024 and projected growth of 2.6% annually, organizations implementing specialized MRO CPQ solutions report quote turnaround improvements of up to 83% and substantial gains in service revenue capture. The transition from reactive repairs to configured service packages represents a transformative business opportunity for heavy equipment manufacturers, dealers, service providers, and maintenance management teams.

Picture this: A construction site’s excavator suddenly breaks down during a critical foundation project. The equipment operator scrambles to contact the authorized dealer, who manually reviews extensive parts catalogs, checks inventory across multiple distribution warehouses, and calculates complex labor costs using outdated spreadsheets. Three days later, the maintenance quote arrives—but by then, the project deadline has slipped, costing thousands in liquidated damages and productivity losses.

This scenario plays out countless times across heavy machinery operations worldwide. The global MRO market reached $440.8 billion in 2025, yet many equipment operators still struggle with antiquated, reactive repair processes that prioritize emergency fixes over preventive maintenance strategies.

According to McKinsey research, organizations implementing digital maintenance strategies can reduce equipment downtime by 30-50% while lowering maintenance costs by 15-25%. However, most heavy equipment operations continue relying on manual processes that create costly delays.

Heavy machinery downtime carries severe financial consequences across multiple industries. Construction operations face substantial productivity losses and project delays when critical equipment fails unexpectedly. Mining operations experience particularly severe impacts, with large haul trucks valued at millions of dollars and some mining equipment worth almost $15,000 per hour of operation, making downtime extremely costly. Industry analysis from Deloitte indicates that unplanned downtime costs industrial companies an average of $50 billion annually across manufacturing and heavy equipment sectors.

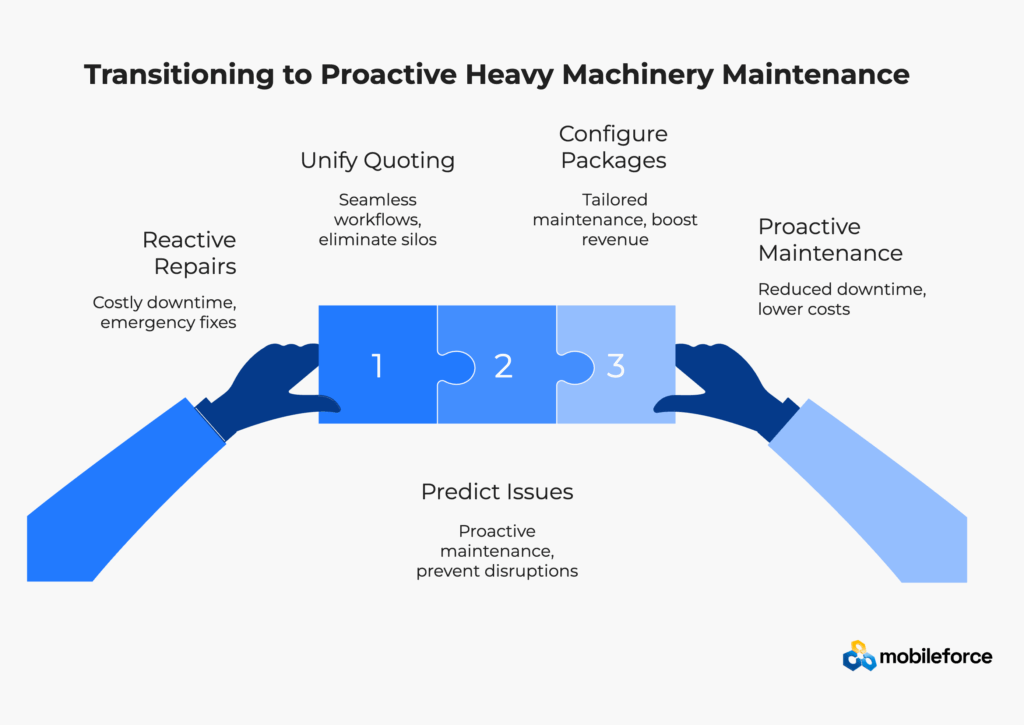

The traditional maintenance approach creates a vicious cycle: equipment failures trigger emergency repairs, which demand immediate parts sourcing at premium prices, require overtime labor costs, and often result in suboptimal temporary fixes that increase future breakdown probability. Research from PwC demonstrates that reactive maintenance strategies cost 3-5 times more than proactive approaches while delivering inferior equipment reliability outcomes.

But what if there was a more intelligent approach? What if service providers could transition from reactive emergency repairs to proactive, configured maintenance packages that predict equipment issues before they cause operational disruptions? Modern revenue operations platforms are enabling precisely this transformation by unifying quoting, service delivery, and customer management into seamless workflows that eliminate traditional operational silos.

Configure-Price-Quote (CPQ) technology represents a fundamental transformation in how heavy equipment service providers, authorized dealers, and maintenance organizations approach maintenance and repair operations. Unlike traditional CPQ systems designed primarily for initial equipment sales and standard product configuration, MRO-focused CPQ platforms address the unique complexities of aftermarket service delivery, spare parts management, and equipment lifecycle optimization.

CPQ for heavy machinery maintenance is specialized software that automates the complete process of configuring maintenance services, calculating accurate pricing including parts and labor costs, and generating comprehensive quotes for equipment repair, overhaul, and preventive maintenance programs. These platforms integrate with enterprise resource planning (ERP) systems, customer relationship management (CRM) platforms, and field service management solutions to create seamless workflows from initial service inquiry through work order completion and invoice generation.

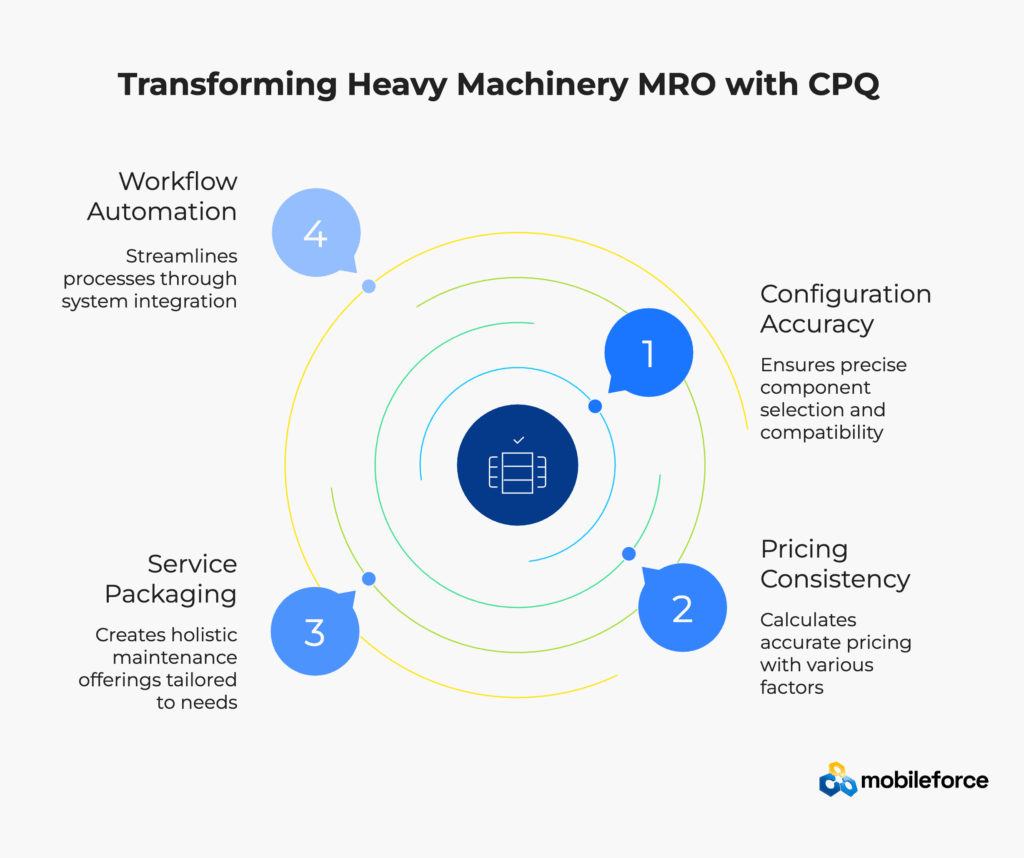

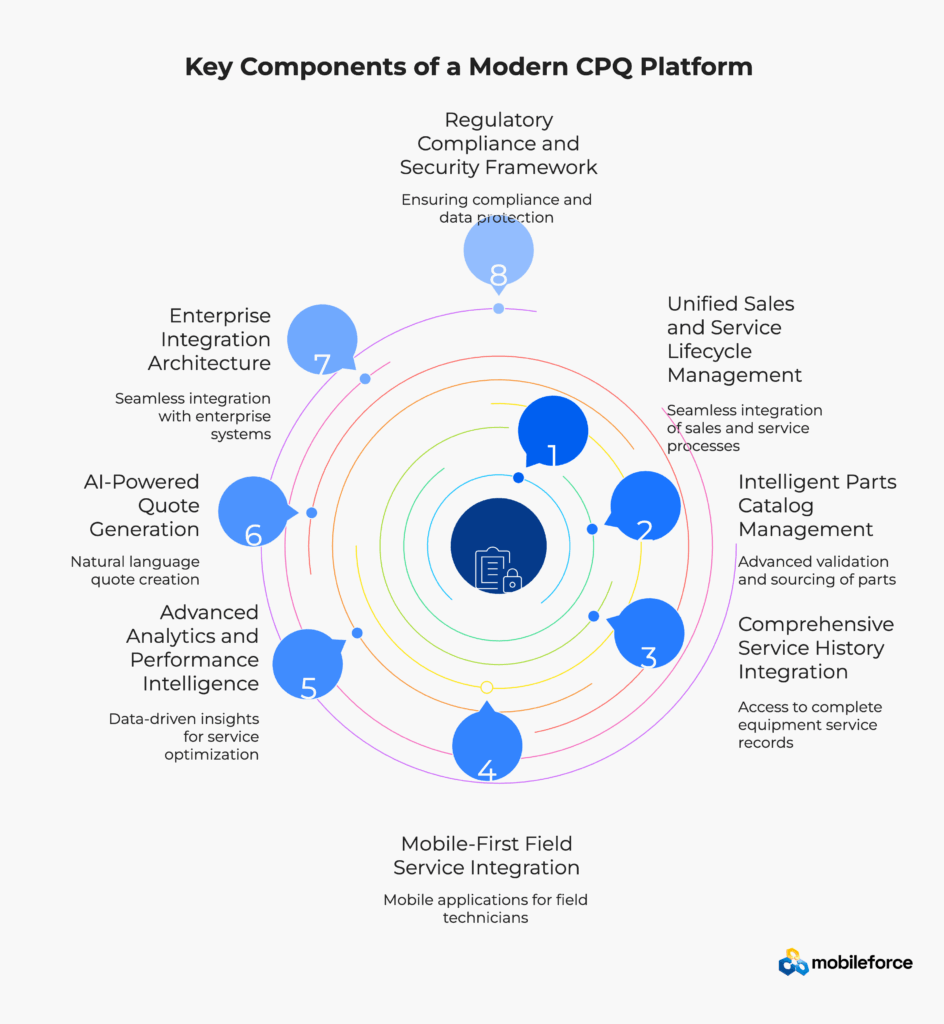

Modern CPQ platforms transform heavy machinery MRO by addressing four critical operational areas: configuration accuracy, pricing consistency, service packaging, and workflow automation.

Advanced Configuration Management: Heavy construction equipment, mining machinery, and industrial systems contain thousands of components across multiple manufacturers, model variations, software versions, and specification updates. A single excavator might incorporate 15,000+ individual parts, each with specific compatibility requirements, torque specifications, and installation procedures. CPQ systems encode these intricate relationships digitally, ensuring service technicians select compatible components based on equipment serial numbers, software versions, operational configurations, and manufacturer recommendations.

Intelligent Dynamic Pricing Engine: Service pricing involves multifaceted calculations including parts costs with supplier markups, skilled labor rates varying by technician certification levels, travel time and mileage expenses, urgency factors for emergency repairs, warranty considerations, and regional cost adjustments. Advanced CPQ solutions automatically calculate precise pricing while applying appropriate volume discounts, loyalty program benefits, markup rules based on service complexity, and regional market adjustments.

Modern platforms now incorporate AI-powered quoting assistants like AskCPQ that enable service advisors to generate complex quotes using natural language requests. For example, a service advisor can simply ask “Create a quote for excavator hydraulic system overhaul including premium parts, 24-hour service, and 2-year warranty” and receive an accurate, compliant quote within seconds. This conversational AI approach dramatically reduces training requirements while ensuring pricing accuracy across all service scenarios.

Comprehensive Service Package Creation: Rather than quoting individual repairs reactively, CPQ enables service providers to create holistic maintenance offerings that combine multiple service elements. These might include scheduled preventive maintenance programs, comprehensive parts replacement kits, skilled labor bundles with certified technicians, extended warranty coverage options, emergency response guarantees, and performance monitoring services—all configured based on specific equipment requirements, operational patterns, and customer preferences.

Workflow Automation and Integration: Modern CPQ platforms integrate seamlessly with existing business systems to automate manual processes. This includes automatic parts inventory checking across multiple warehouses, real-time technician availability scheduling, customer service history retrieval, warranty status verification, and regulatory compliance documentation generation.

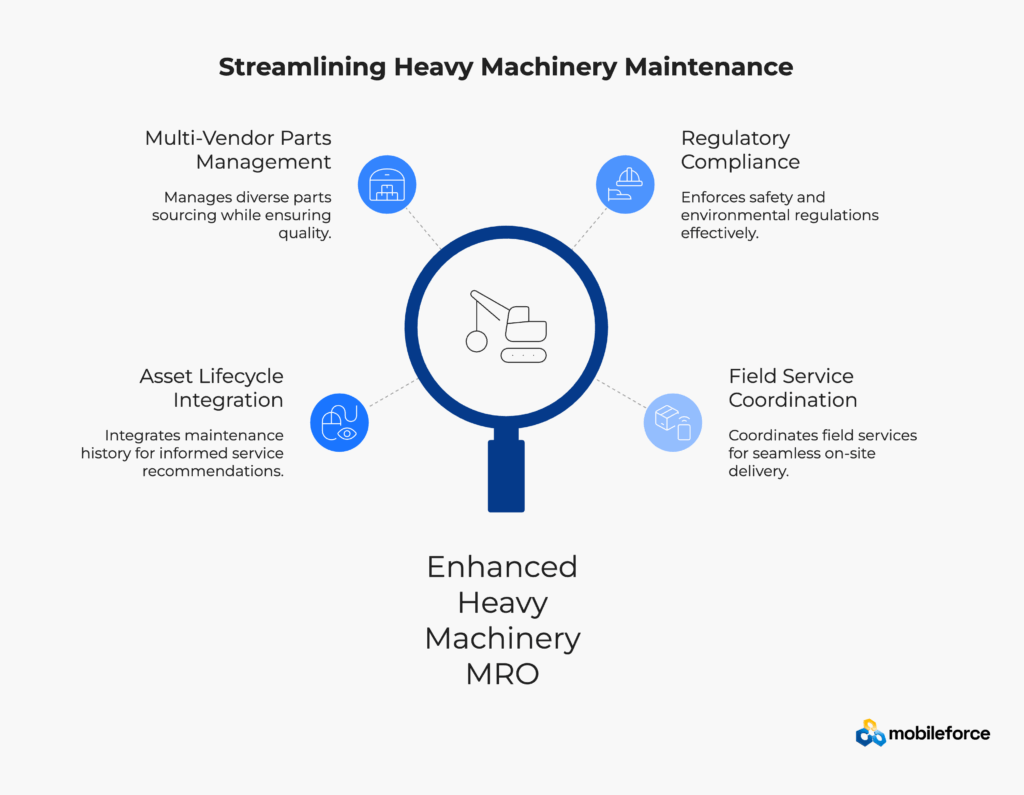

Heavy machinery MRO demands specialized capabilities that extend far beyond standard CPQ functionality:

Comprehensive Asset Lifecycle Integration: Equipment maintenance history, previous repair records, warranty status information, operational hour tracking, and performance analytics all influence service recommendations and pricing strategies. CPQ systems integrate with computerized maintenance management systems (CMMS) and enterprise asset management (EAM) platforms to access this critical contextual information automatically.

Complex Multi-Vendor Parts Management: Heavy machinery often requires components from original equipment manufacturers (OEMs), authorized aftermarket suppliers, remanufacturing sources, and specialty fabrication providers. CPQ platforms must handle sophisticated sourcing rules while maintaining quality standards, delivery commitments, warranty compliance, and cost optimization objectives.

Regulatory Compliance and Safety Validation: Safety regulations, environmental standards, operational certifications, and industry-specific requirements vary significantly by geography, application, and operational environment. CPQ systems enforce these complex requirements during configuration processes to prevent non-compliant service packages that could create liability exposure or operational disruptions.

Advanced Field Service Coordination: Unlike office-based quoting scenarios, MRO CPQ must integrate seamlessly with field service management systems to coordinate parts availability verification, skilled technician scheduling, travel logistics, on-site service delivery coordination, and real-time status updates throughout the service delivery process.

Recent comprehensive market analysis reveals substantial opportunities for CPQ transformation across heavy machinery MRO operations, driven by digital transformation initiatives and increasing demand for operational efficiency optimization.

The maintenance, repair, and operations sector demonstrates robust expansion across multiple key performance indicators. North American MRO distribution reached $161.70 billion in 2024, with projections indicating steady 2.6% compound annual growth rate (CAGR) through 2030, driven by infrastructure investment increases and manufacturing sector expansion.

Global MRO market valuation reached $747.61 billion in 2024, with forecasts projecting growth to $947.71 billion by 2034 at 2.40% CAGR, reflecting sustained demand for maintenance services across industrial sectors.

Industrial MRO operations—encompassing heavy machinery maintenance, manufacturing equipment service, and construction equipment repair—represent the largest market segment at 33.4% of total market share. This segment dominance reflects the critical role heavy equipment plays in manufacturing operations, construction projects, mining activities, agricultural production, and infrastructure development.

Predictive maintenance technologies are fundamentally reshaping MRO strategies across heavy equipment operations. Advanced analytics and machine learning are enabling organizations to reduce equipment downtime by 30-50% while lowering maintenance costs by 15-25%, enabling maintenance teams to transition from reactive repair approaches to proactive service scheduling.

According to comprehensive industry research, 95% of manufacturing firms now view Industry 4.0 technologies as essential strategic opportunities, while 91% consider them critical for maintaining competitive advantages in their respective markets.

Internet of Things (IoT) sensor integration is accelerating across heavy equipment fleets. These connected devices enable real-time monitoring of engine performance, hydraulic system pressure, track wear patterns, and component stress levels, providing maintenance teams with unprecedented visibility into equipment condition and performance trends.

Artificial intelligence and machine learning applications in MRO operations show significant adoption growth, with organizations implementing automated failure prediction, intelligent parts inventory optimization, and dynamic maintenance scheduling based on operational patterns and environmental conditions.

The United States maintains dominant market position in North American MRO operations, controlling 87.1% of total market revenue share. This concentration reflects extensive manufacturing infrastructure, favorable economic conditions, significant presence of equipment manufacturers, and substantial ongoing investments in industrial automation and infrastructure modernization.

Canada represents the secondary market with projected significant growth rates during the forecast period, driven by manufacturing sector expansion and increasing adoption of advanced maintenance technologies across mining, forestry, and energy sectors.

Chemical industry operations lead MRO demand with 18.3% market share, reflecting the sector’s complex equipment requirements and stringent maintenance standards. Food, beverage, and tobacco segments project fastest growth rates, driven by increasing automation adoption and food safety regulatory compliance requirements.

Market Segment | 2024 Market Share | Key Growth Drivers | Primary Applications |

Industrial MRO | 33.4% | Automation, predictive maintenance | Heavy equipment, manufacturing systems |

Facility MRO | 18.7% | Smart building integration | HVAC, electrical, structural maintenance |

Aviation MRO | 15.2% | Fleet expansion, safety regulations | Aircraft maintenance, ground support equipment |

Heavy Construction Equipment | 12.3% | Infrastructure investment, automation | Excavators, bulldozers, cranes, loaders |

Mining Equipment | 8.4% | Resource demand, safety compliance | Haul trucks, drilling equipment, processing machinery |

Heavy equipment downtime costs vary significantly by industry application and equipment type. Construction operations experience average downtime costs of $2,000-$8,000 per day per machine, depending on equipment size and project criticality. Mining operations face substantially higher impacts, with large haul trucks costing $30,000-$75,000 daily in lost production.

Manufacturing facilities report average equipment downtime costs of $50,000 per hour for critical production lines, emphasizing the financial imperative for effective maintenance management and rapid service response capabilities.

Emergency repair costs typically run 300-500% higher than planned maintenance expenses, reflecting premium parts pricing, overtime labor rates, expedited shipping charges, and opportunity costs associated with production disruptions.

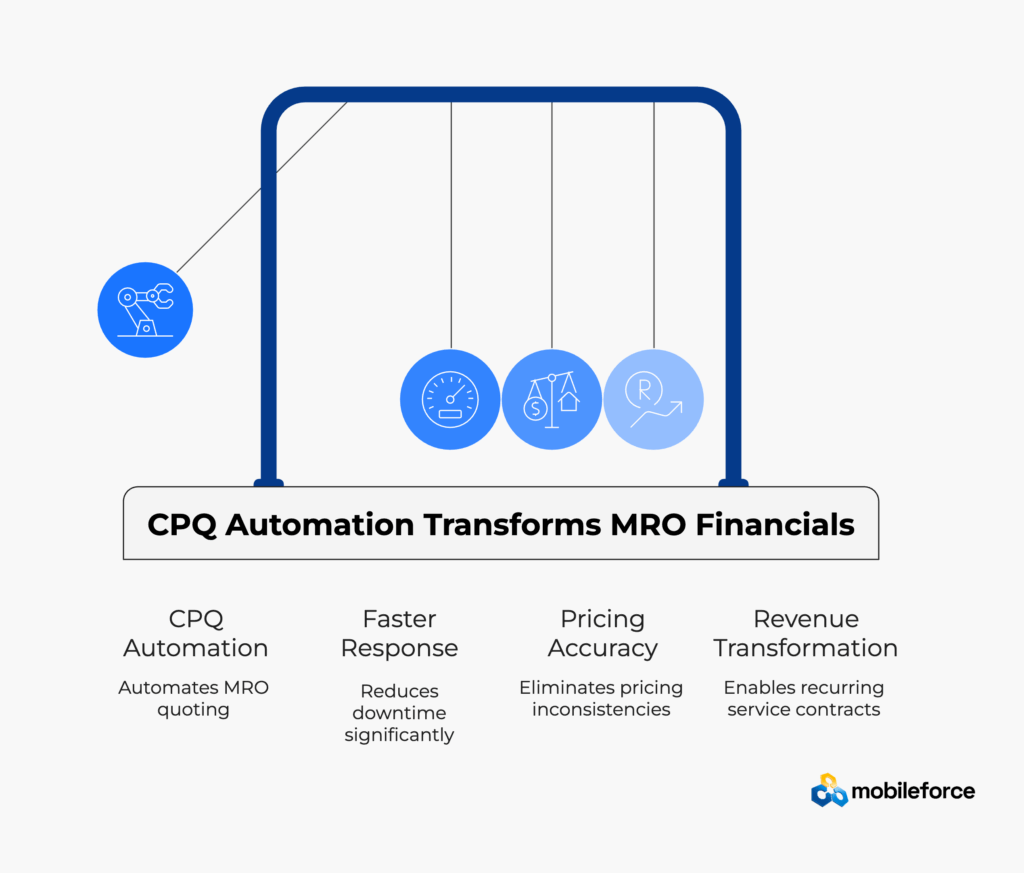

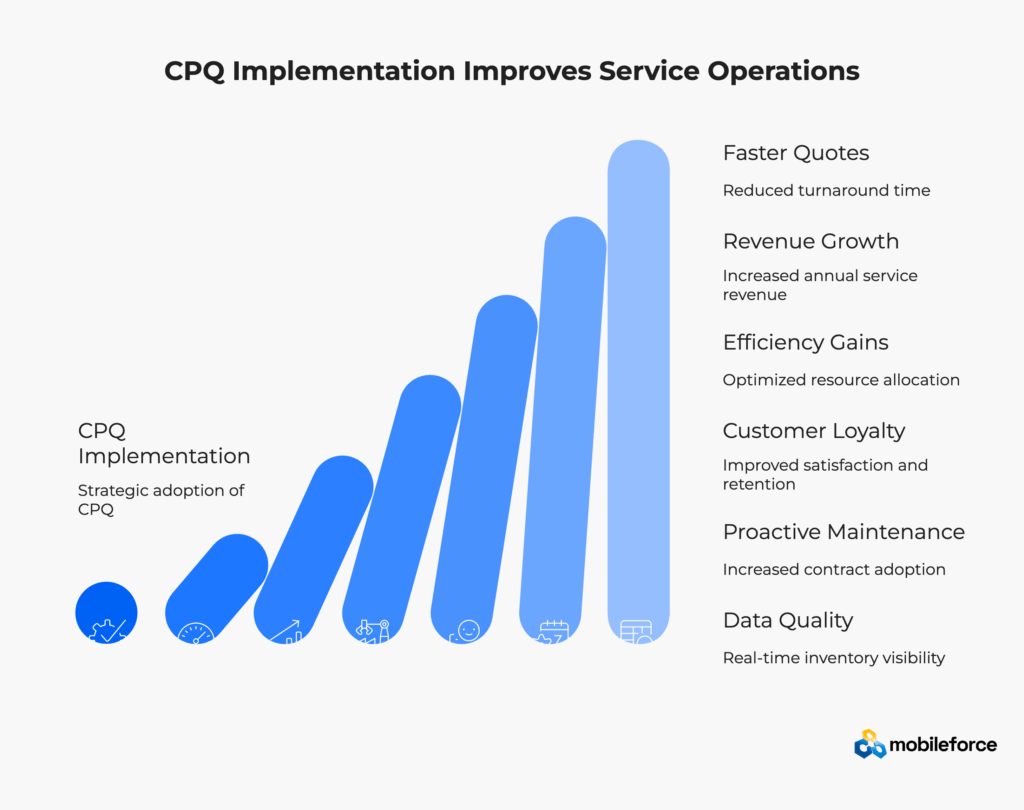

The financial justification for CPQ adoption in heavy machinery MRO extends far beyond simple quote acceleration to comprehensive business model transformation, revenue optimization, and operational cost reduction across multiple organizational functions.

Traditional MRO quoting processes often require extensive timeframes for complex repairs and maintenance planning. Service teams must manually verify parts compatibility across multiple manufacturer catalogs, confirm inventory availability across distributed warehouse locations, calculate labor requirements based on technician skill levels and availability, coordinate with engineering teams for custom solutions, and obtain management approval for pricing exceptions.

CPQ automation compresses these traditionally lengthy timeframes dramatically. What previously required extensive manual coordination and multi-departmental review now executes in minutes through automated workflows. For equipment operators managing critical production schedules, this speed improvement directly translates to minimized operational downtime and accelerated project completion timelines.

Consider the BMW Group’s comprehensive implementation of predictive maintenance systems integrated with intelligent quoting platforms, which achieved filter replacement cost reductions from EUR 14,400 to EUR 6,600 (approximately $15,300 to $7,000) within 24 months. This 54% cost reduction demonstrates the substantial financial impact of transitioning from reactive maintenance approaches to proactive, CPQ-enabled service strategies.

Heavy machinery service operations face complex pricing challenges including fluctuating parts costs, varying labor rates across geographic regions, seasonal demand variations, and customer-specific contract terms. Manual pricing calculations frequently result in underpricing that erodes profit margins or overpricing that reduces competitive positioning.

CPQ systems eliminate pricing inconsistencies through automated calculation engines that factor real-time parts costs, current labor rates, approved discount structures, and customer-specific pricing agreements. This automation reduces warranty claims resulting from pricing errors, prevents costly rework due to incorrect quotes, and maintains regulatory compliance across different jurisdictions.

Advanced CPQ platforms enable dynamic pricing optimization based on market conditions, competitor analysis, and customer value metrics, helping service providers maximize profit margins while maintaining competitive positioning.

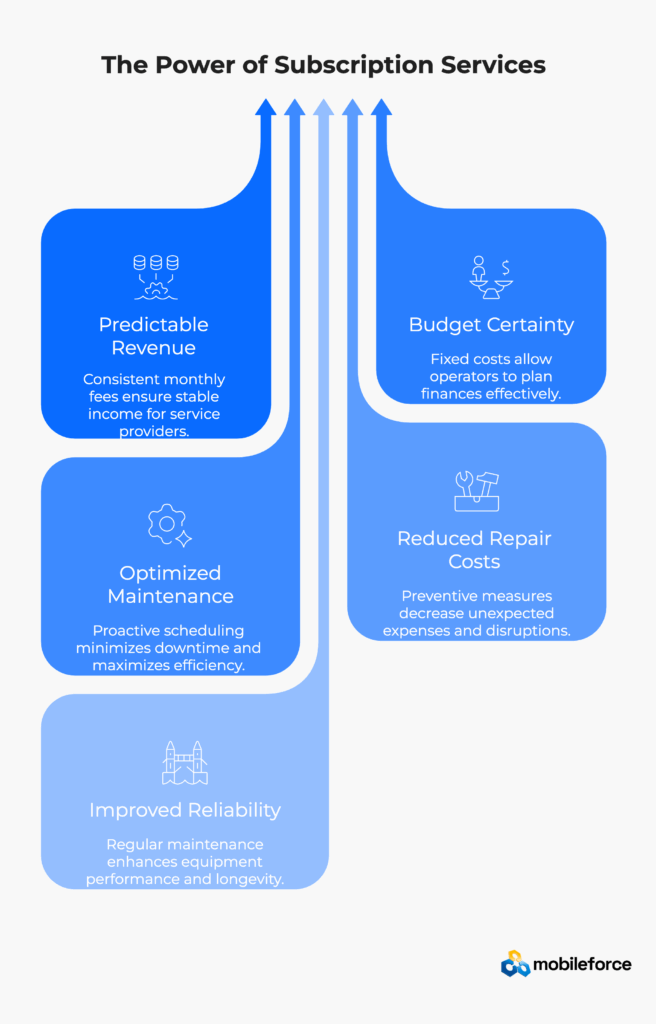

Perhaps most significantly, CPQ enables service providers to evolve from transactional repair sales to recurring service relationships through comprehensive maintenance contracts. Instead of waiting for equipment failures to generate service revenue, providers can offer proactive maintenance contracts, scheduled parts replacement programs, comprehensive service agreements with guaranteed response times, and performance-based maintenance models.

This strategic shift creates multiple business advantages:

Organizations implementing comprehensive MRO CPQ solutions typically achieve measurable improvements across multiple key performance indicators. Research from Aberdeen Group indicates that best-in-class organizations using advanced CPQ systems achieve 28% higher quote-to-order conversion rates and 35% faster sales cycle completion compared to industry averages.

Quote Generation Speed: Service quotes that previously required 2-5 days for complex maintenance scenarios now generate in 15-45 minutes, representing 85-95% time reduction and enabling same-day customer response capabilities. Modern platforms with AI-powered quote generation can further accelerate this process through natural language processing and automated configuration recommendations. AI assistants like AskCPQ enable service advisors to generate quotes conversationally, simply by describing customer requirements in natural language rather than navigating complex configuration menus.

Service Revenue Growth: Companies report 25-40% increases in annual service revenue within 12-18 months of implementation, driven by improved customer satisfaction, expanded service offerings, and increased contract adoption rates. Research on revenue operations demonstrates that organizations with mature revenue operations practices achieve 36% higher customer lifetime value through improved service delivery and relationship management. AI-powered quoting capabilities enable service teams to respond faster to customer inquiries while providing more comprehensive service recommendations through intelligent upselling suggestions.

Operational Cost Reduction: Administrative overhead typically decreases 30-50% as automated processes reduce manual data entry, eliminate duplicate work, and streamline approval workflows. This efficiency improvement enables service teams to handle significantly higher quote volumes without proportional staffing increases.

Performance Metric | Before Implementation | After Implementation | Improvement |

Average Quote Generation Time | 48-72 hours | 15-30 minutes | 88% reduction |

Service Revenue Growth | Baseline | +35-42% | Within 12 months |

Customer Satisfaction (NPS) | 6.8 | 8.7 | +28% improvement |

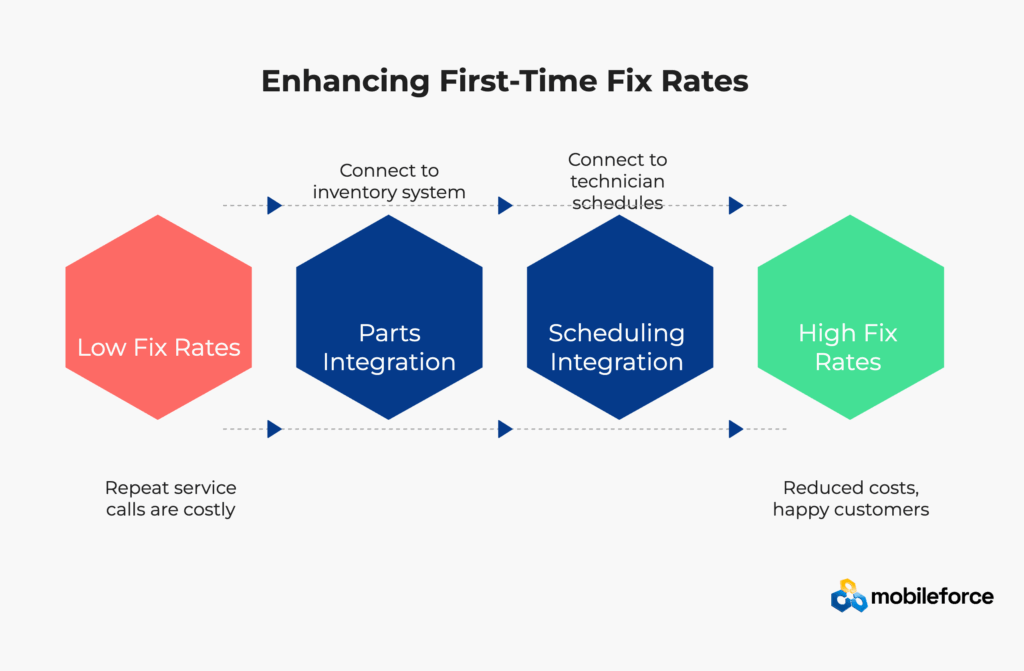

First-Time Fix Rate | 67% | 84% | +17 percentage points |

Administrative Time (Service Advisors) | 65% | 23% | 42 point reduction |

Preventive Maintenance Contracts | 18% | 52% | +34 percentage points |

Customer Satisfaction Improvements: Net Promoter Scores commonly increase 2-3 points, with customers specifically citing faster response times, more comprehensive service options, and improved communication throughout the service delivery process. Harvard Business Review research indicates that increasing customer satisfaction scores by just one point can improve customer retention by 5-7% and increase revenue per customer by 10-15%.

First-Time Fix Rate Enhancement: Integration with parts inventory and technician scheduling systems improves first-time fix rates by 15-25%, reducing repeat service calls and associated travel costs. This improvement directly impacts customer satisfaction while reducing operational costs for service providers.

CPQ implementation creates sustainable competitive advantages that are difficult for competitors to replicate quickly. Service providers gain capabilities to respond faster to customer inquiries, offer more comprehensive service packages, provide accurate pricing consistently, and deliver superior customer experience throughout the service lifecycle.

These advantages become particularly valuable in competitive bidding situations where response time and service comprehensiveness often determine contract awards.

The most successful heavy equipment service operations are recognizing that isolated CPQ systems, while valuable, represent only one component of a comprehensive revenue optimization strategy. Modern revenue engagement platforms that unify configure-price-quote functionality with field service management and customer relationship optimization are emerging as the preferred approach for organizations seeking transformational business results.

Traditional CPQ implementations often create new operational silos despite their internal efficiency improvements. Sales teams generate quotes efficiently, but coordination with field service scheduling remains manual. Service delivery teams receive work orders, but lack real-time visibility into customer communication and quote details. Management gains insights into quoting performance, but struggles to optimize the complete quote-to-cash-to-service lifecycle.

Heavy equipment operations require seamless coordination across multiple functional areas: initial customer inquiry and needs assessment, equipment specification and service package configuration, accurate pricing with real-time inventory verification, quote approval and customer communication, service scheduling and resource allocation, field service delivery and completion, billing and payment processing, and ongoing relationship management and upselling opportunities.

Advanced revenue engagement platforms address these coordination challenges by providing unified workflows that eliminate handoffs and information gaps between departments. Rather than implementing separate systems for sales, service, and customer management, these integrated platforms enable seamless data flow and process automation across the complete customer lifecycle.

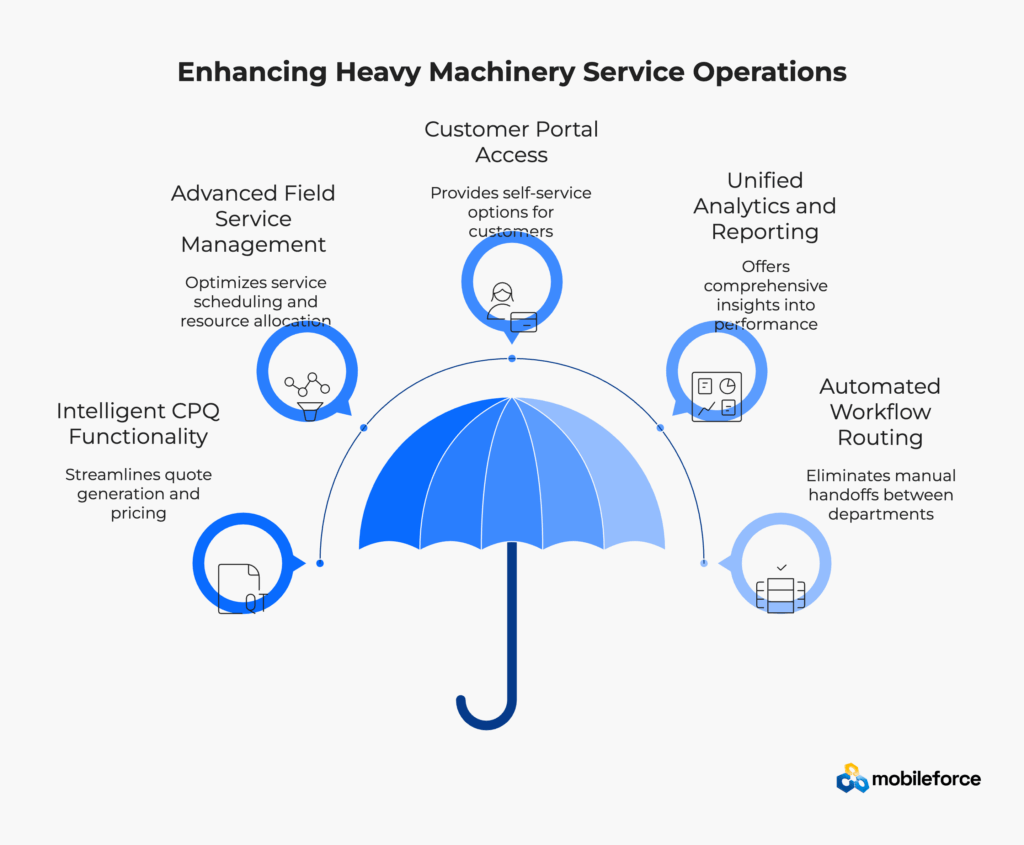

Comprehensive revenue operations platforms typically include several integrated capabilities: intelligent CPQ functionality designed for complex manufacturing and service environments, advanced field service management with mobile applications and real-time coordination, customer portal access for self-service scheduling and communication, unified analytics and reporting across all revenue functions, and automated workflow routing that eliminates manual handoffs between departments.

When CPQ functionality operates within a unified revenue platform, heavy equipment service providers achieve several operational advantages beyond standalone implementations. Quote-to-service coordination becomes automatic, with approved quotes immediately flowing into field service scheduling systems. Customer communication remains consistent throughout the service lifecycle, with all teams accessing unified customer interaction histories.

Real-time visibility enables service managers to optimize resource allocation based on quote pipeline, current service commitments, and technician availability. Analytics provide comprehensive insights into complete customer lifecycle performance rather than isolated departmental metrics.

Organizations evaluating unified revenue operations platforms should prioritize solutions designed specifically for complex manufacturing and service environments. Modern no-code platforms enable rapid customization without technical expertise, allowing service teams to adapt workflows and processes as business requirements evolve.

Critical evaluation criteria include native integration architecture that eliminates complex middleware requirements, mobile-first design optimized for field service operations, comprehensive analytics covering the complete quote-to-cash-to-service lifecycle, and proven implementation methodologies that minimize disruption during transition periods.

Traditional CPQ Approach | Unified Revenue Operations | Key Advantages |

Isolated quote generation | Integrated quote-to-service workflow | Eliminated handoffs, faster delivery |

Manual service coordination | Automated scheduling integration | Improved resource utilization |

Departmental reporting | Unified lifecycle analytics | Complete visibility, better optimization |

Separate customer interactions | Consistent communication platform | Enhanced customer experience |

Point solution integration | Native platform architecture | Reduced complexity, lower costs |

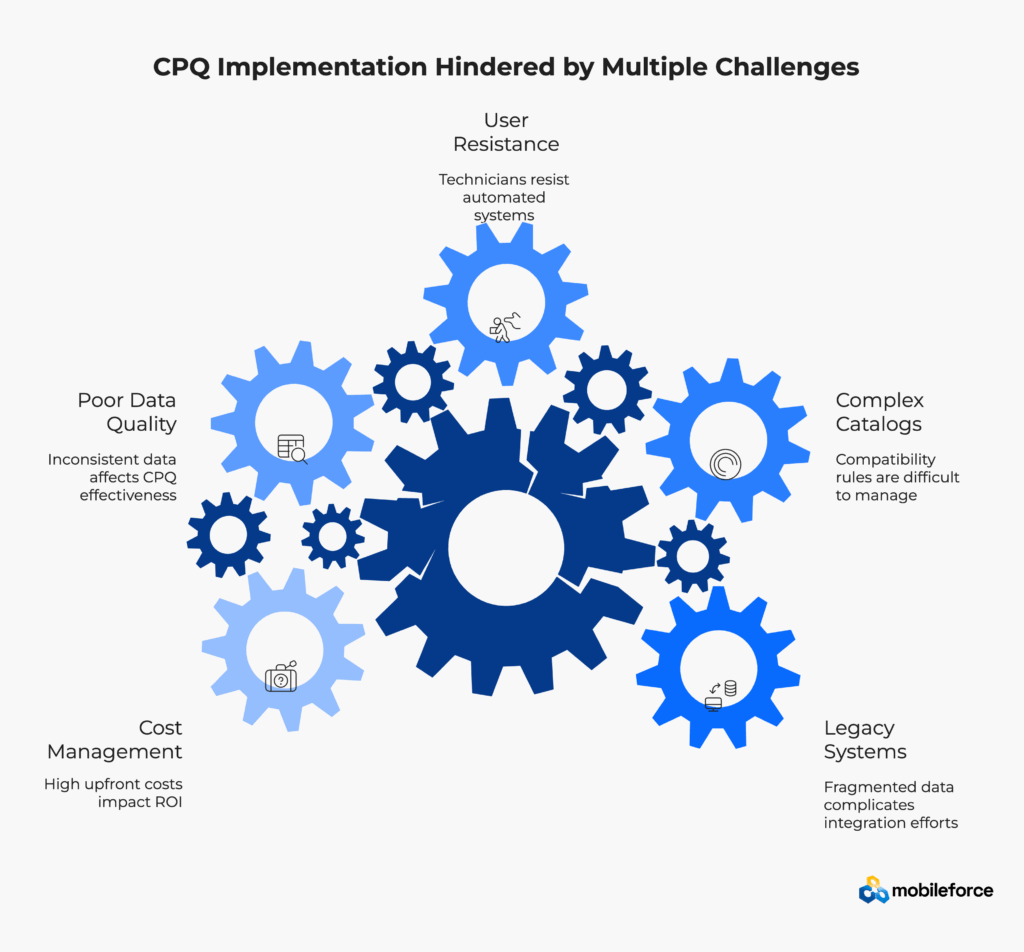

While the financial and operational benefits of MRO CPQ are substantial, many heavy equipment service providers encounter significant implementation challenges that require systematic approaches and strategic planning to overcome successfully.

Heavy equipment dealers and service organizations typically operate with fragmented technology architectures: separate databases for parts inventory management, customer relationship management, service history tracking, billing and accounting systems, and technician scheduling platforms. These siloed systems often use incompatible data formats, different identification schemes, and varying update frequencies that complicate integration efforts.

Strategic Solution Approach: Begin with comprehensive data mapping and system architecture assessment. Identify core integration points between CPQ and primary systems including ERP for inventory visibility, CRM for customer data synchronization, and field service management for work order coordination. Implement standardized data formats and establish real-time synchronization protocols. Consider middleware solutions or integration platforms that can bridge compatibility gaps between systems.

Prioritize bidirectional data flow to ensure CPQ systems can both retrieve information from existing systems and update records based on quote activity. Establish data governance procedures to maintain accuracy and consistency across all integrated platforms.

Heavy machinery parts catalogs contain millions of components with sophisticated compatibility relationships that extend beyond simple part numbers. A single hydraulic pump might have dozens of variants depending on engine model, serial number ranges, software versions, geographic markets, and environmental operating conditions. These relationships often involve multiple manufacturers, aftermarket suppliers, and remanufactured alternatives.

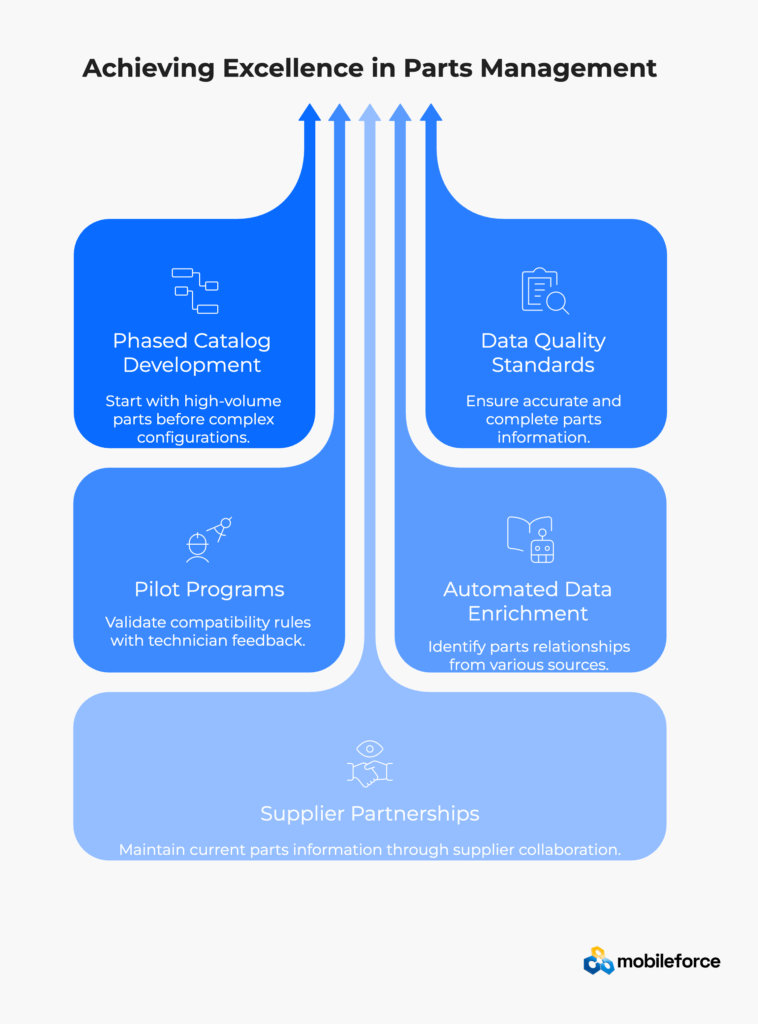

Strategic Solution Approach: Implement phased catalog development starting with high-volume, standardized components before addressing complex custom configurations. Establish clear data quality standards for parts information including complete compatibility matrices, accurate specifications, and current pricing information.

Use pilot programs with experienced service technicians to validate compatibility rules and identify missing relationships. Develop feedback mechanisms that allow field technicians to report compatibility issues and suggest improvements based on real-world experience.

Consider investing in automated data enrichment tools that can identify parts relationships from manufacturer documentation, service manuals, and historical repair records. Establish ongoing partnerships with parts suppliers to maintain current information about availability, pricing, and technical specifications.

Service technicians and sales teams accustomed to manual processes may resist automated systems, particularly if interfaces are complex, unintuitive, or require significant changes to established workflows. Resistance often increases when users perceive new systems as threats to their expertise or job security.

Strategic Solution Approach: Involve key users in vendor selection and system configuration processes to ensure tools meet practical needs and workflow requirements. Prioritize platforms with intuitive interfaces that minimize learning curves and provide clear value to daily operations.

Implement comprehensive change management programs that communicate benefits clearly, address concerns proactively, and provide adequate support during transition periods. Establish internal champions who can demonstrate system value and assist colleagues with adoption challenges.

Create gradual rollout strategies that introduce functionality incrementally rather than replacing all processes simultaneously. Allow users to maintain familiar backup procedures during initial implementation phases to reduce anxiety and build confidence.

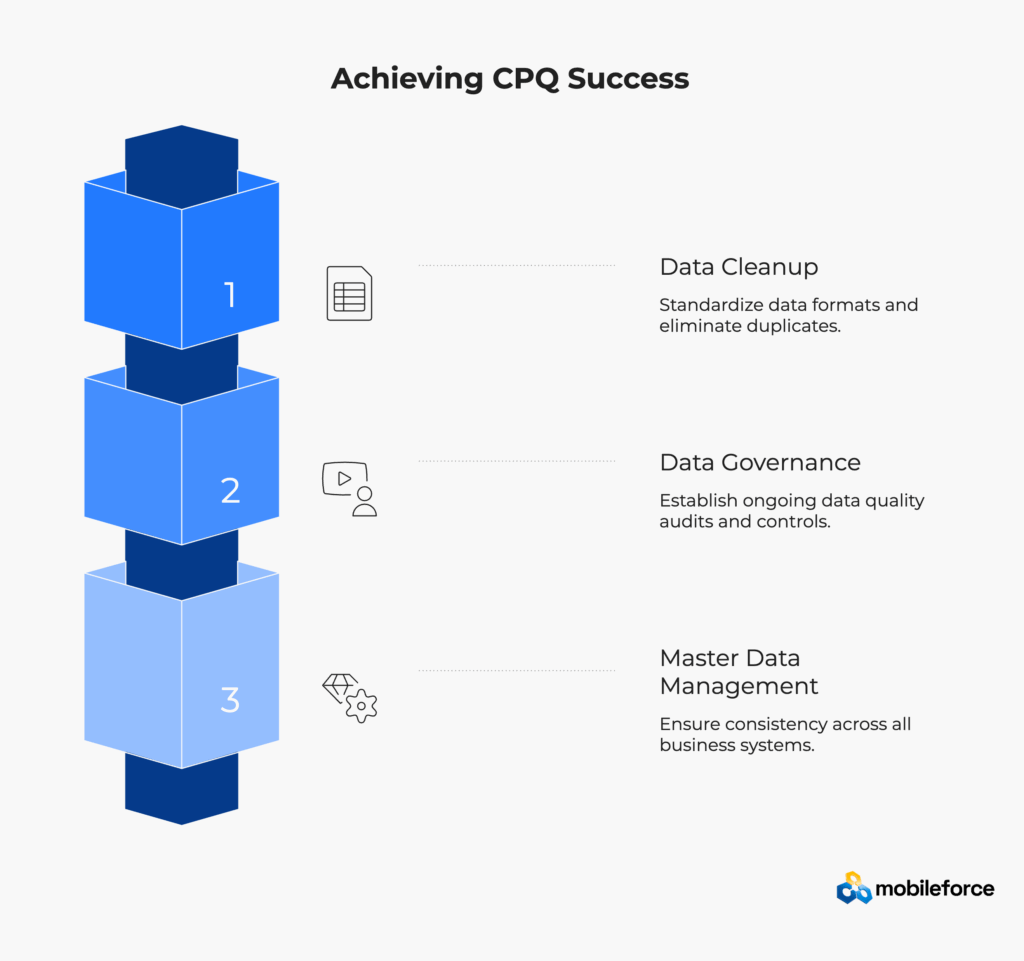

CPQ systems require exceptionally clean, standardized data to function effectively. Many organizations discover significant data quality issues during implementation including duplicate customer records, inconsistent parts naming conventions, missing equipment specifications, outdated pricing information, and incomplete service history records.

Strategic Solution Approach: Conduct comprehensive data audit before CPQ deployment to identify quality issues, standardization needs, and missing information. Establish dedicated data cleanup initiatives with clear timelines, responsibility assignments, and quality metrics.

Implement ongoing data governance procedures including regular quality audits, standardized data entry protocols, and automated validation rules that prevent future quality degradation. Consider this process an opportunity to improve overall information management practices that benefit operations beyond CPQ requirements.

Establish master data management practices that ensure consistency across all business systems. Create standardized naming conventions, identification schemes, and data formats that support both current needs and future system expansions.

CPQ implementation requires significant upfront investments in software licensing, system integration, data cleanup, training programs, and ongoing maintenance. Organizations must balance these costs against projected benefits while managing cash flow impacts during transition periods.

Strategic Solution Approach: Develop detailed cost-benefit analyses that include both direct costs (software, implementation services, training) and indirect costs (staff time, temporary productivity reductions, potential revenue impacts). Compare these against quantifiable benefits including time savings, error reduction, and revenue growth opportunities.

Consider phased implementation approaches that spread costs over longer periods while delivering incremental benefits. Start with high-impact, low-complexity scenarios that demonstrate clear ROI before expanding to more complex applications.

Negotiate vendor contracts that align costs with achieved benefits through outcome-based pricing, performance guarantees, or phased payment schedules tied to implementation milestones.

Implementation Challenge | Typical Duration | Critical Success Factors | Risk Mitigation Strategies | |||

Legacy system integration | 4-8 months | Executive sponsorship, dedicated resources | Pilot testing, phased rollout | |||

Parts catalog cleanup | 3-6 months | Data quality standards, supplier cooperation | Automated validation, ongoing governance | |||

User training and adoption | 2-4 months | Change management, user involvement | Champion programs, gradual introduction | |||

Data standardization | 6-12 months | Governance procedures, quality metrics | Master data management, validation rules | |||

Performance optimization | Ongoing | Regular monitoring, feedback integration | Continuous improvement, analytics review | |||

Implementation Challenge | Impact Severity | Recommended Timeline |

| |||

Legacy system integration | High | 3-6 months |

| |||

Parts catalog cleanup | Medium | 2-4 months |

| |||

User training | Medium | 1-3 months |

| |||

Data standardization | High | 4-8 months |

| |||

Selecting the optimal CPQ platform for heavy machinery MRO operations requires comprehensive understanding of specific functional requirements, technical capabilities, and integration specifications that differentiate specialized MRO solutions from general-purpose CPQ platforms.

The ideal CPQ platform provides seamless integration between initial equipment sales processes and complete aftermarket service lifecycle management. This unified approach ensures consistent customer experience from initial equipment purchase through decades of maintenance relationships, service contract renewals, and eventual equipment replacement or upgrade cycles.

Essential capabilities include comprehensive equipment configuration with integrated service options, bundled maintenance packages available during initial sales processes, automated transition from sales teams to service departments, unified customer communication across all touchpoints, and consistent pricing and contract management throughout equipment lifecycle.

Advanced platforms provide customer portal access where equipment owners can review service history, schedule maintenance appointments, order replacement parts, and monitor equipment performance metrics through integrated dashboards.

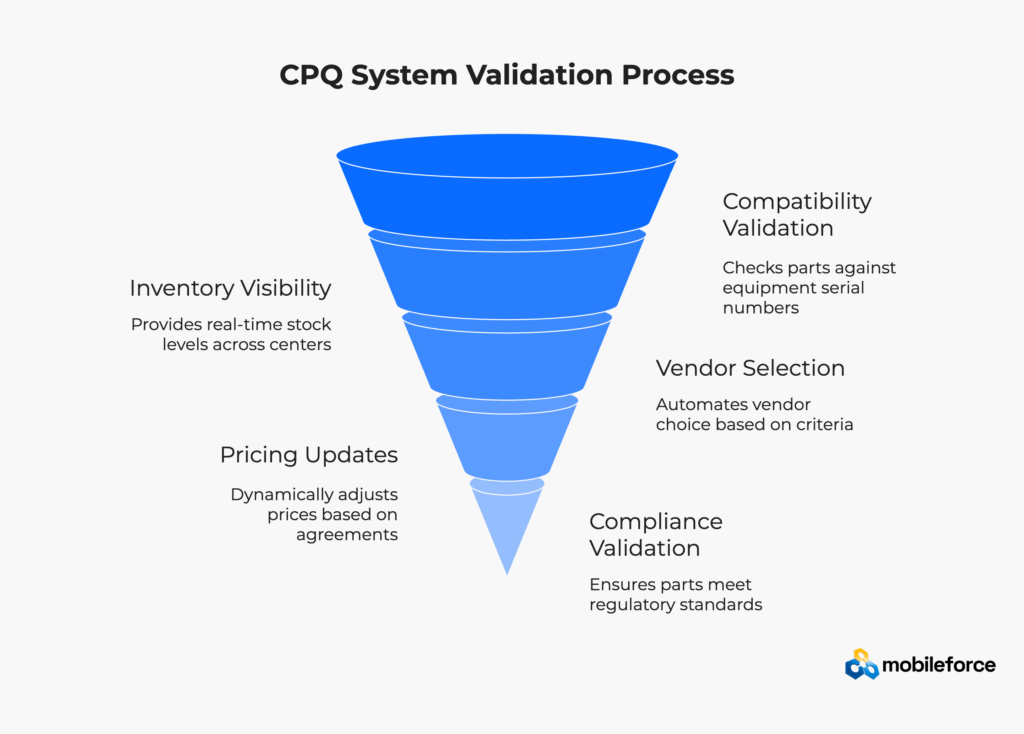

Heavy machinery CPQ systems must navigate extraordinarily complex parts relationships with sophisticated validation capabilities. The platform should provide automatic compatibility validation based on equipment serial numbers, real-time inventory visibility across multiple distribution centers, multi-vendor sourcing options with automated vendor selection, support for remanufactured and aftermarket components, custom fabrication requirement handling, and obsolete parts substitution recommendations.

Advanced catalog management includes automated parts cross-referencing between manufacturers, dynamic pricing updates based on supplier agreements, quantity break calculations for volume purchases, lead time estimation for special orders, and environmental or regulatory compliance validation for specific applications.

The compatibility engine should prevent invalid configurations that could compromise safety, performance, or warranty coverage while suggesting optimal alternatives based on availability, cost, and delivery timeframes.

Effective MRO quoting requires deep equipment context and operational intelligence. The CPQ system must integrate seamlessly with computerized maintenance management systems (CMMS), enterprise asset management (EAM) platforms, and IoT sensor networks to access complete equipment history, current operational status, and predictive maintenance recommendations.

Critical integration capabilities include complete service and repair history access, warranty status and coverage verification, operational hours and usage pattern analysis, predictive maintenance alert integration, performance trend analysis and recommendations, and regulatory compliance and certification tracking.

This intelligence enables service advisors to recommend appropriate maintenance intervals, identify potential issues before failures occur, and propose comprehensive service packages based on actual equipment condition and operational patterns.

Service technicians frequently operate in remote locations with limited or unreliable connectivity. The CPQ platform must provide robust mobile applications optimized for field environments with comprehensive offline capability, intuitive touch-based interfaces, real-time synchronization when connectivity permits, integrated camera functionality for documentation, and electronic signature capture for work order completion.

Advanced field service management integration ensures CPQ-generated quotes flow seamlessly into work order management systems, parts procurement processes, technician scheduling platforms, customer communication systems, and billing integration for streamlined invoicing.

Mobile capabilities should include GPS-enabled location services, barcode scanning for parts verification, photo documentation of equipment conditions, and offline access to service manuals and technical documentation.

MRO CPQ platforms should provide comprehensive analytics capabilities covering service revenue trends and forecasting, parts utilization patterns and inventory optimization, maintenance cycle analysis and optimization recommendations, customer satisfaction metrics and improvement opportunities, technician productivity and efficiency analysis, and profitability analysis by service type and customer segment.

Advanced analytics enable predictive insights including equipment failure probability based on service history, optimal maintenance scheduling recommendations, parts demand forecasting for inventory planning, customer churn risk identification, and service pricing optimization based on market conditions.

Modern heavy equipment MRO operations benefit significantly from AI-powered quoting assistants that enable service teams to generate complex quotes using natural language interactions. Advanced AI assistants like AskCPQ understand heavy equipment terminology, parts relationships, and service workflows, allowing service advisors to create quotes by simply describing customer requirements conversationally.

This capability proves particularly valuable for heavy machinery MRO where service scenarios can be highly complex and variable. Instead of navigating multiple configuration screens and pricing tables, service advisors can request “Generate quote for Cat 320 excavator annual maintenance package including hydraulic system service, track replacement, and emergency response coverage” and receive accurate, compliant quotes within seconds.

AI-powered configuration also reduces training requirements for new service advisors while ensuring consistent pricing and service recommendations across all customer interactions. The system learns from successful quote patterns and automatically suggests optimal service packages based on equipment type, operational environment, and customer history.

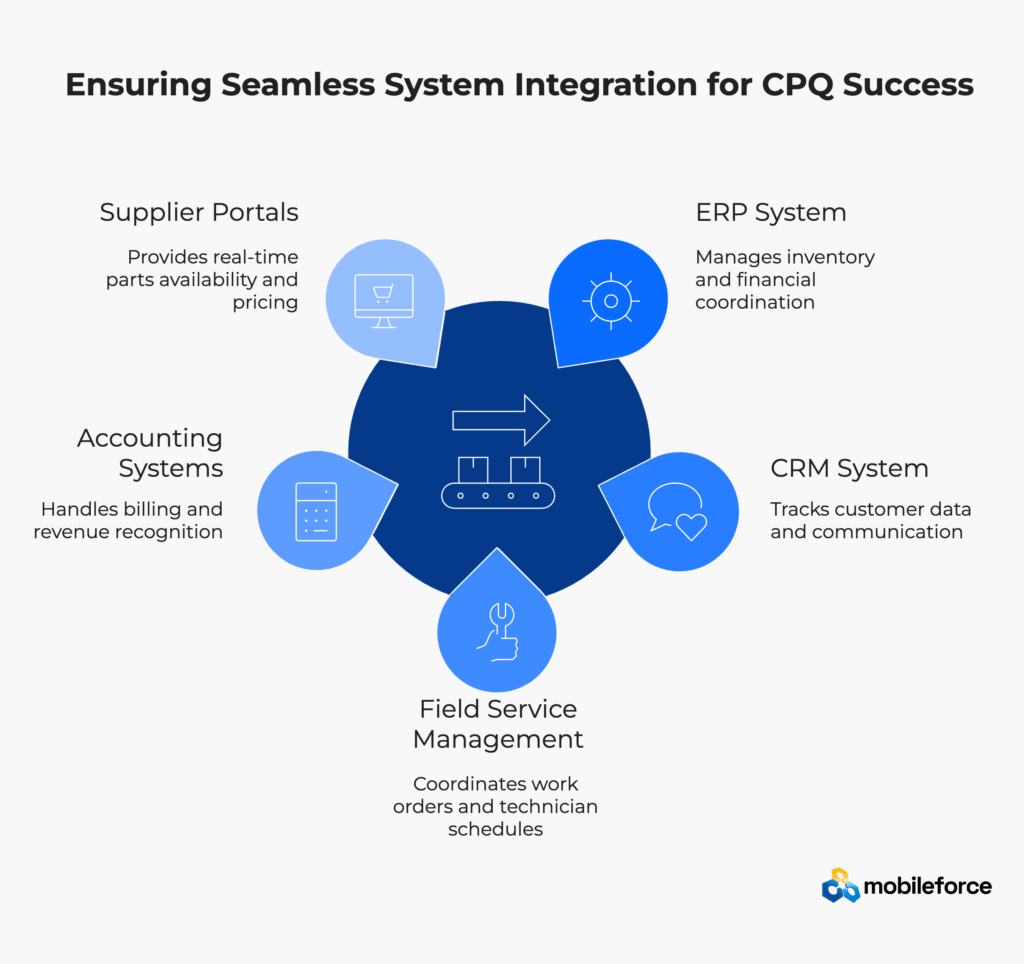

Heavy equipment service operations require CPQ platforms that integrate seamlessly with enterprise systems including ERP systems for inventory, procurement, and financial management, CRM platforms for customer relationship management, field service management for work order coordination, accounting systems for billing and revenue recognition, and business intelligence platforms for reporting and analytics.

Integration architecture should support real-time data synchronization, API-based connectivity for custom integrations, standard protocol support (REST, SOAP, EDI), security compliance for data protection, and scalability to support growth in users, transactions, and data volumes. Advanced platforms with native integration capabilities reduce implementation complexity while ensuring reliable data flow across all business systems.

Heavy equipment operations often involve regulated industries with specific requirements for safety documentation, environmental compliance, data protection, and audit trail maintenance. CPQ platforms must provide comprehensive compliance capabilities including automated regulatory requirement checking, complete audit trail maintenance, data encryption and security protocols, role-based access controls, and electronic signature capabilities for legal documentation.

Security features should include multi-factor authentication, data backup and disaster recovery, compliance with industry standards (SOC 2, GDPR, HIPAA where applicable), and regular security updates and monitoring. Enterprise-grade platforms typically provide comprehensive security certifications and compliance documentation to meet stringent industry requirements.

Different CPQ vendors offer varying approaches to implementation, significantly impacting timeline, cost, and success probability. Organizations should evaluate vendor methodologies carefully to ensure alignment with business objectives and resource constraints.

Implementation Approach | Timeline | Key Benefits | Potential Challenges | Best Fit Organizations |

Traditional Custom Development | 8-18 months | Complete customization, specific requirements | High cost, complex maintenance, long timeline | Large enterprises with unique needs |

Pre-Built Industry Solution | 4-8 months | Industry-specific features, proven functionality | Limited customization, vendor dependency | Mid-market companies with standard needs |

No-Code Platform Configuration | Rapid deployment, user control, flexible changes | Learning curve, feature limitations | Growing companies needing agility | |

Hybrid Approach | 6-12 months | Balanced customization and speed | Complex vendor coordination | Large organizations with mixed requirements |

Modern no-code platforms are increasingly preferred for heavy equipment MRO applications due to their ability to adapt quickly to changing business requirements without requiring extensive technical expertise or vendor dependency for modifications.

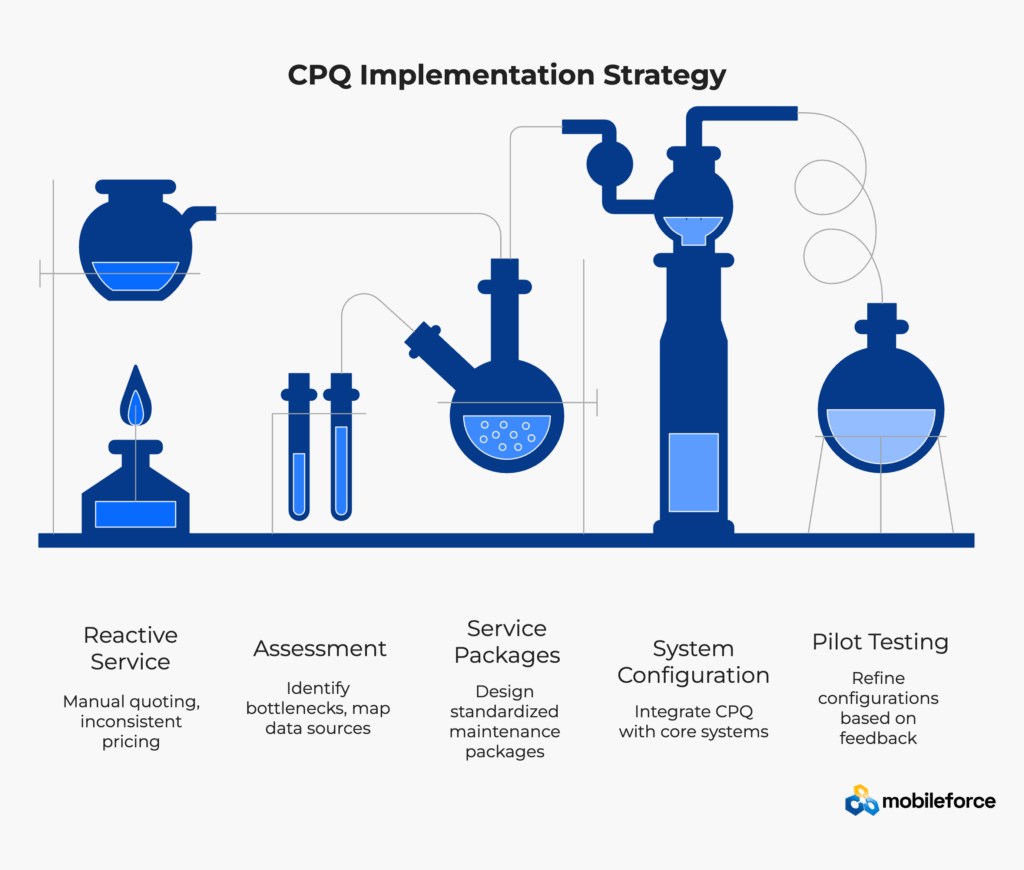

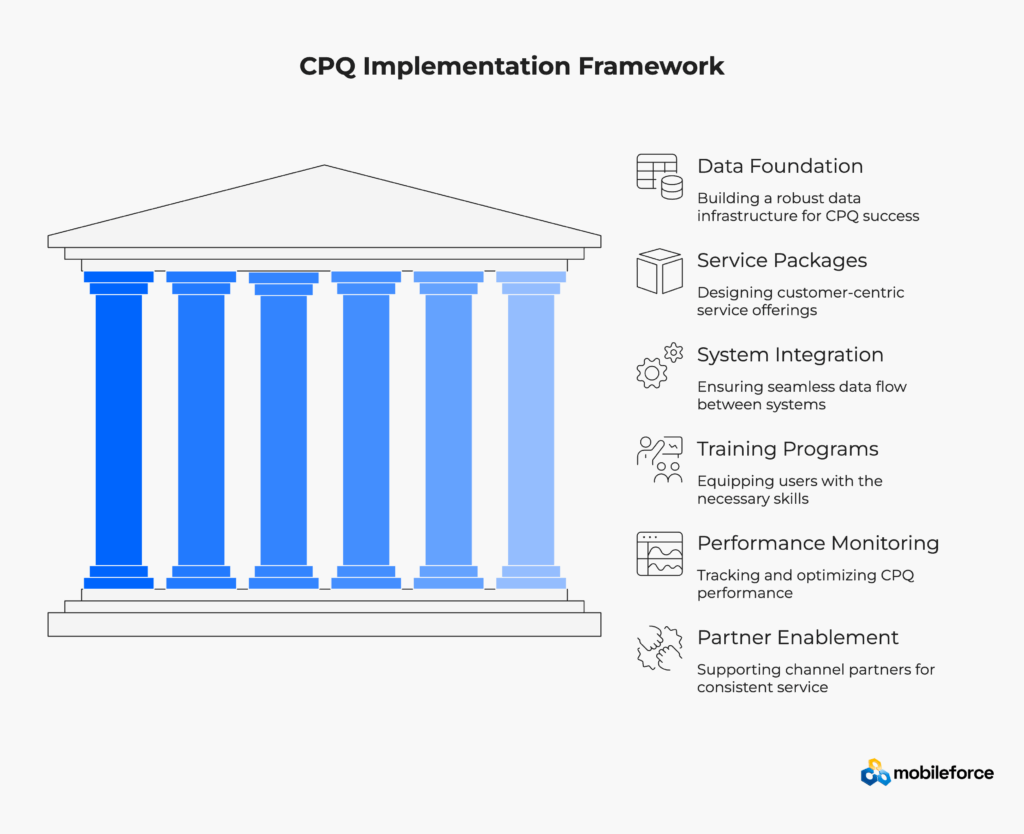

Successfully transitioning to CPQ-enabled proactive service requires systematic planning and phased implementation.

Begin with comprehensive assessment of current quoting processes, identifying bottlenecks, error sources, and improvement opportunities. Map existing data sources and integration requirements while establishing data quality standards.

Create detailed inventory of service offerings, pricing rules, and approval workflows. This documentation becomes the foundation for CPQ configuration.

Design standardized service packages for common maintenance scenarios: routine preventive maintenance, seasonal preparation, and equipment overhaul programs. These packages should include parts, labor, and timeline specifications.

Develop pricing models that consider equipment age, utilization patterns, and operational environments. Create tiered service levels to accommodate different customer budgets and requirements.

Configure the CPQ platform with validated parts catalogs, compatibility rules, and pricing models. Establish integrations with core systems including ERP, CRM, and field service management platforms.

Implement approval workflows for non-standard configurations and pricing exceptions. Create user roles and permissions that align with organizational structure.

Launch pilot programs with select customers and service scenarios. Monitor quote accuracy, generation speed, and customer satisfaction metrics. Use pilot feedback to refine configurations and improve user experience.

Gradually expand pilot scope to include more complex scenarios and additional user groups.

Complete system rollout across all service teams and customer segments. Implement comprehensive training programs and ongoing support procedures.

Establish regular review cycles to optimize pricing rules, service packages, and system performance based on operational experience.

Implementation Phase | Duration | Key Success Metrics |

Assessment & Foundation | 1-2 months | Data quality score, integration requirements |

Service Package Development | 2-3 months | Package coverage, pricing accuracy |

System Configuration | 3-4 months | Integration completion, user acceptance |

Pilot Testing | 2-3 months | Quote accuracy, customer satisfaction |

Full Deployment | 1-2 months | User adoption rate, service revenue growth |

To illustrate the comprehensive impact of CPQ implementation in heavy machinery MRO, consider the documented experience of a regional construction equipment dealer serving the Northeastern United States, managing a fleet service territory covering over 500 active customers across construction, landscaping, and municipal operations.

This established dealer operated a traditional service model characterized by significant operational inefficiencies and missed revenue opportunities. When customers contacted the service department with equipment problems, service advisors manually researched parts requirements across multiple manufacturer catalogs, checked inventory availability across six regional warehouse locations, calculated labor costs using outdated spreadsheet templates, coordinated with field service technicians for availability scheduling, and obtained multiple management approvals for pricing exceptions and warranty considerations.

Quote generation typically required 48-72 hours for standard repairs and up to one week for complex overhauls or emergency situations. During peak construction seasons (April through October), these delays resulted in customers frequently seeking faster service from competitors, particularly for urgent repairs needed to maintain project schedules.

The company’s aftermarket service revenue represented only 28% of total annual sales, significantly below industry benchmark expectations of 45-55% for established equipment dealers. Service advisors dedicated approximately 65% of their time to administrative tasks including parts research, inventory checking, pricing calculations, and quote preparation, leaving minimal time for customer consultation and relationship development.

Quote accuracy problems occurred in approximately 15% of service estimates, leading to frequent rework, customer disputes, margin erosion, and damaged customer relationships. Common issues included incorrect parts selection due to manual catalog errors, outdated pricing information causing margin losses, and labor estimate inaccuracies resulting in project cost overruns.

Working with modern revenue operations platforms that integrate CPQ functionality with field service management and customer relationship management, the dealer implemented a comprehensive digital transformation solution addressing quoting processes, service delivery coordination, and customer communication workflows. Unlike traditional point solutions that create operational silos, the unified platform approach eliminated handoffs between departments while maintaining data consistency across all customer touchpoints.

The implementation leveraged no-code configuration capabilities that enabled rapid customization without extensive technical resources or vendor dependency. This approach allowed the dealer to adapt system workflows to existing operational procedures while gradually introducing process improvements based on best practice recommendations.

The comprehensive solution included several integrated components: complete equipment configuration database covering all major manufacturer models and specifications, standardized service packages for common maintenance scenarios including preventive maintenance, seasonal preparation, and emergency repairs, real-time parts inventory integration across all warehouse locations and supplier networks, mobile field service applications with offline functionality for technicians working in remote locations, automated workflow routing for approvals and customer communication, and comprehensive analytics dashboard for performance monitoring and optimization.

Integration capabilities connected the revenue operations platform with existing enterprise systems including ERP systems for inventory management and financial coordination, CRM platforms for customer data synchronization and communication tracking, accounting systems for automated billing and revenue recognition, supplier portals for real-time parts availability and pricing updates, and business intelligence tools for advanced reporting and analytics.

According to industry research, organizations implementing unified revenue operations approaches achieve 19% faster revenue growth and 15% higher profitability compared to those using disconnected systems. The dealer’s experience aligned closely with these industry benchmarks through improved operational efficiency and enhanced customer satisfaction.

Within 18 months of full implementation, the dealer achieved remarkable improvements across multiple key performance indicators, demonstrating the transformative potential of comprehensive CPQ adoption in heavy equipment service operations.

Quote Generation Speed and Customer Response: Service quotes that previously required 48-72 hours for standard repairs now generated in 12-25 minutes, representing an 88% reduction in quote turnaround time. Complex overhaul estimates decreased from 5-7 days to 2-4 hours, enabling same-day response capabilities that significantly improved competitive positioning during peak demand periods.

Service Revenue Growth and Profitability: Annual service revenue increased 42% within the first year, driven primarily by improved customer satisfaction, expanded maintenance contract offerings, faster competitive response times, and enhanced upselling capabilities through comprehensive service package recommendations. Service profit margins improved 18% due to more accurate pricing, reduced rework costs, and optimized parts procurement through automated vendor selection.

Operational Efficiency and Resource Optimization: Service advisor productivity increased substantially as administrative task time decreased from 65% to 23% of total work hours, allowing significantly more focus on customer consultation, relationship development, and solution design. Overall service department efficiency improved 35% through automated workflows, eliminating duplicate data entry and streamlining approval processes.

Customer Satisfaction and Retention Improvements: Net Promoter Score improved from 6.8 to 8.7, with customers specifically citing faster response times, more comprehensive service options, clearer communication throughout service delivery, and improved first-time fix rates. Customer retention rates increased 22%, with service contract renewals improving from 34% to 58% of eligible customers.

Preventive Maintenance Adoption and Contract Revenue: Proactive maintenance contracts grew from 18% to 52% of active service customers, providing predictable recurring revenue and reducing emergency repair requirements. This shift enabled better resource planning, improved inventory management, and enhanced customer equipment reliability through scheduled maintenance programs.

Technology Integration and Data Quality: Real-time inventory visibility eliminated stockout delays in 78% of previous problem scenarios. Automated parts compatibility checking reduced configuration errors by 91%. Integration with mobile field service applications improved first-time fix rates from 67% to 84%, significantly reducing repeat service calls and associated travel costs.

These comprehensive improvements demonstrate how strategic CPQ implementation can transform heavy equipment service operations from reactive, inefficient processes to proactive, customer-centric service delivery models that generate sustainable competitive advantages and improved financial performance.

Selecting the optimal CPQ platform for heavy machinery MRO requires systematic evaluation across multiple dimensions including technical capabilities, implementation methodology, ongoing support quality, and total cost of ownership. Organizations should develop comprehensive vendor assessment frameworks that address both immediate needs and long-term strategic objectives.

Evaluation Criteria | Weight | Key Considerations | Evaluation Questions |

Industry Expertise | 25% | Heavy equipment experience, MRO specialization | Has vendor worked with similar operations? Do they understand parts compatibility challenges? |

Technical Capabilities | 20% | Integration depth, mobile functionality, analytics | Does platform support complex configurations? Are mobile capabilities robust? |

Implementation Approach | 15% | Methodology, timeline, support quality | What is implementation timeline? How comprehensive is training? |

15% | Licensing, implementation, ongoing costs | What are hidden costs? How does pricing scale with growth? | |

Scalability & Flexibility | 10% | Growth support, customization options | Can platform adapt to changing needs? How easy are modifications? |

Customer References | 10% | Similar implementations, success stories | Can vendor provide relevant customer references? |

Security & Compliance | 5% | Data protection, regulatory compliance | Does platform meet industry security standards? |

Modern CPQ platforms for heavy equipment MRO should provide unified revenue operations capabilities that eliminate traditional silos between sales, service, and customer management functions. Organizations should prioritize platforms with native integration architecture rather than bolt-on solutions that create additional complexity and maintenance overhead.

No-code configuration capabilities enable organizations to adapt systems quickly without vendor dependency or technical expertise requirements. This flexibility becomes critical as business requirements evolve and competitive pressures demand rapid response capabilities.

Organizations considering CPQ adoption for heavy machinery MRO operations should implement proven best practices and systematic approaches to maximize implementation success, ensure sustainable adoption, and achieve optimal return on investment across all operational areas.

Success in CPQ implementation requires exceptionally clean, standardized, and well-organized data across parts catalogs, equipment specifications, service histories, customer records, and supplier information. Organizations should invest substantial time upfront in comprehensive data cleanup and standardization procedures that establish consistent data formats, eliminate duplicate records, standardize naming conventions, verify data accuracy, and create comprehensive data validation rules.

Establish ongoing data governance procedures including regular data quality audits, automated validation protocols, standardized data entry procedures, role-based data access controls, and comprehensive backup and recovery procedures. Consider this intensive process an valuable opportunity to improve overall information management practices that benefit operations far beyond CPQ requirements, including improved inventory management, enhanced customer service capabilities, and better financial reporting accuracy.

Implement master data management practices that ensure consistency across all integrated business systems. Create standardized identification schemes for parts, equipment, customers, and suppliers that support current operational needs while providing scalability for future system expansions and business growth.

Evolve beyond traditional reactive repair quoting to comprehensive service offerings that provide clear value propositions for equipment operators. Research shows that companies offering integrated service packages achieve 15-20% higher customer retention rates and 25% improvement in customer lifetime value compared to transactional approaches.

Develop sophisticated service packages that combine preventive maintenance schedules, predictable parts replacement programs, comprehensive warranty coverage options, emergency response guarantees with guaranteed response times, performance monitoring and optimization services, and operator training and certification programs. Advanced CPQ platforms enable dynamic service package configuration based on equipment type, operational environment, and customer-specific requirements.

Consider different customer segments and their unique operational requirements when designing service offerings. Construction contractors have different equipment utilization patterns, budget constraints, and seasonal demands compared to mining operations, agricultural users, or municipal fleet operators. Develop segment-specific packages that address these unique needs while maintaining operational efficiency for service delivery teams.

Create tiered service levels that accommodate different customer budgets and risk tolerance levels. Basic packages might include essential maintenance and standard response times, while premium packages could offer predictive maintenance, priority response, guaranteed uptime commitments, and advanced performance optimization services. Manufacturing industry research demonstrates that tiered service approaches increase average contract value by 30-40% while improving customer satisfaction through choice and flexibility.

CPQ success depends fundamentally on smooth, reliable data flow between integrated systems including enterprise resource planning (ERP) for inventory management and financial coordination, customer relationship management (CRM) for customer data and communication tracking, field service management for work order coordination and technician scheduling, accounting systems for billing and revenue recognition, and supplier portals for real-time parts availability and pricing updates.

McKinsey research on digital integration indicates that organizations with fully integrated systems achieve 25% faster time-to-market for new services and 20% reduction in operational costs through eliminated redundancies and improved data quality.

Plan comprehensively for bidirectional data synchronization to maintain consistency across all integrated platforms. Ensure that CPQ systems can both retrieve information from existing systems and update records based on quote activity, service delivery completion, and customer interactions. Modern no-code integration approaches can significantly simplify this complex process while reducing integration costs and implementation timelines by up to 60%.

Establish robust integration testing procedures that validate data accuracy, system performance, and error handling capabilities across all connected systems. Implement comprehensive monitoring and alerting systems that identify integration issues quickly and enable rapid resolution to maintain operational continuity.

User adoption ultimately determines CPQ success more than technical capabilities or system functionality. Develop comprehensive, role-specific training programs that address the unique needs of service advisors (quote generation, customer consultation, system navigation), field technicians (mobile applications, work order integration, offline functionality), managers (reporting, analytics, performance monitoring), and administrative personnel (system configuration, user management, integration maintenance).

Provide ongoing support programs including refresher training sessions, new feature introductions, best practice sharing, and continuous improvement workshops. Consider establishing internal champion programs where experienced users provide peer support, assist colleagues with system questions, and identify opportunities for process improvements and optimization.

Implement gradual change management strategies that introduce new functionality incrementally rather than replacing all existing processes simultaneously. Allow users to maintain familiar backup procedures during initial implementation phases to reduce anxiety, build confidence, and demonstrate system value through successful experience.

Establish comprehensive key performance indicators covering operational efficiency metrics (quote generation speed, service delivery times, first-time fix rates), customer satisfaction measurements (Net Promoter Scores, customer retention rates, service contract renewal rates), financial performance indicators (service revenue growth, profit margin improvements, cost reduction achievements), and user adoption metrics (system utilization rates, training effectiveness, user satisfaction scores).

Implement regular review cycles to assess performance against established benchmarks, identify optimization opportunities, analyze customer feedback and suggestions, review competitive positioning, and evaluate emerging technology opportunities. Use advanced analytics capabilities to identify trends in parts usage patterns, service delivery efficiency, customer preferences and behavior, and market opportunities for service expansion.

Create continuous improvement processes that incorporate user feedback, customer suggestions, performance data analysis, and industry best practice adoption. Establish cross-functional teams that regularly review system performance and recommend configuration adjustments, process improvements, and technology enhancements.

If operating through dealer networks or service partners, ensure CPQ systems support consistent pricing strategies, standardized service delivery processes, unified customer experience across all channels, comprehensive partner training and support, and performance monitoring and optimization for all channel participants.

Provide comprehensive partner enablement programs including system access and training, marketing support and co-op programs, technical support and troubleshooting assistance, performance monitoring and feedback, and ongoing best practice sharing and collaboration opportunities.

Consider advanced portal capabilities that allow authorized partners to generate quotes independently while maintaining strict adherence to pricing policies, configuration standards, and service quality requirements. This approach enables scalable growth while ensuring consistent customer experience regardless of service delivery channel.

Strategic Priority | Implementation Timeline | Success Measures | Critical Dependencies | |||

Data Foundation Development | 3-6 months | Data quality metrics, system integration success | Executive sponsorship, dedicated resources | |||

Service Package Design | 2-4 months | Package adoption rates, customer feedback scores | Market research, competitive analysis | |||

System Integration Completion | 4-8 months | Data flow accuracy, system performance metrics | Technical expertise, vendor support | |||

Training Program Implementation | 2-3 months | User adoption rates, competency assessments | Change management, user engagement | |||

Performance Monitoring Establishment | Ongoing | KPI achievement, continuous improvement trends | Analytics capabilities, review processes | |||

Channel Partner Enablement | 3-6 months | Partner performance, customer satisfaction consistency | Partner cooperation, training effectiveness | |||

Strategic Priority | Implementation Timeline | Success Measures |

| |||

Data Foundation | 3-6 months | Data quality metrics, system integration |

| |||

Service Package Design | 2-4 months | Package adoption rates, customer feedback |

| |||

System Integration | 4-8 months | Data flow accuracy, system uptime |

| |||

Training Programs | 2-3 months | User adoption, competency assessments |

| |||

Performance Monitoring | Ongoing | KPI achievement, improvement trends |

| |||

CPQ technology serves as the foundational platform enabling heavy equipment providers to completely reimagine service delivery models, moving beyond traditional break-fix approaches to innovative, technology-enabled service strategies that provide superior value for both service providers and equipment operators.

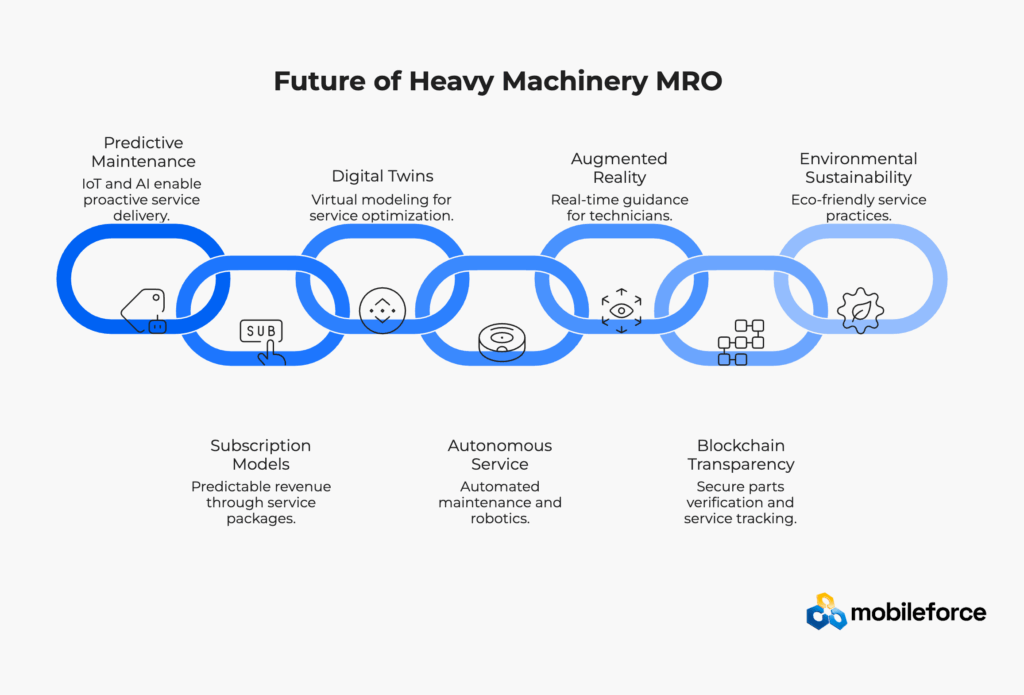

Internet of Things (IoT) sensors and advanced machine learning algorithms increasingly enable heavy equipment to communicate maintenance requirements before failures occur, creating unprecedented opportunities for proactive service delivery. CPQ systems integrated with sophisticated predictive analytics platforms can automatically generate accurate maintenance quotes based on real-time equipment data streams, operational pattern analysis, environmental condition monitoring, and historical performance trends.

This technological convergence transforms service operations from reactive emergency response to proactive partnership relationships, substantially reducing equipment downtime while creating more predictable, recurring revenue streams for service providers. Advanced predictive algorithms can forecast component failure probability, optimize maintenance scheduling for minimal operational disruption, and recommend cost-effective service packages based on actual equipment condition rather than generic maintenance schedules.

Machine learning applications in MRO operations continue expanding rapidly, with organizations implementing automated failure prediction models, intelligent parts inventory optimization systems, dynamic maintenance scheduling based on operational patterns and environmental conditions, and automated quote generation triggered by equipment condition alerts. These capabilities enable service providers to offer guaranteed uptime commitments and performance-based service contracts that align provider incentives with customer operational success.

Progressive equipment manufacturers and service organizations are experimenting with innovative subscription-based service models where customers pay predictable monthly or annual fees for comprehensive maintenance coverage rather than purchasing individual repair services. CPQ systems enable sophisticated subscription pricing models based on equipment usage patterns, operational environment severity, service level requirements, and performance guarantees.

These subscription approaches provide multiple benefits including predictable revenue streams for service providers, budget certainty for equipment operators, optimized maintenance scheduling through proactive planning, reduced emergency repair costs through preventive strategies, and improved equipment reliability through consistent professional maintenance.

Advanced subscription models might include tiered service levels with basic maintenance coverage, premium packages with guaranteed response times and priority parts access, performance-based agreements with uptime guarantees, and comprehensive fleet management services including operator training and optimization consulting.

Advanced equipment manufacturers are developing sophisticated digital representations of heavy machinery that accurately simulate operational conditions, predict maintenance requirements, and optimize performance parameters through virtual modeling and analysis. CPQ systems integrated with digital twin technology can recommend optimal service timing, configure maintenance packages based on virtual equipment condition analysis, and predict service requirements with unprecedented accuracy.

Digital twin integration enables service providers to offer highly sophisticated consultation services including performance optimization recommendations, operational efficiency analysis, predictive failure analysis with specific timeline forecasts, and customized maintenance strategies based on individual equipment usage patterns and operational environments.

This technology advancement allows for virtual testing of maintenance strategies, optimization of service procedures before implementation, and development of highly customized service packages that address specific operational challenges and performance objectives.

As automation technology continues advancing rapidly, certain routine maintenance tasks may become increasingly automated or require minimal human intervention. Future CPQ systems will need to accommodate hybrid service models that seamlessly combine automated maintenance capabilities, robotic assistance for routine procedures, human expertise for complex diagnostics and repairs, and remote monitoring and support services.

Emerging technologies include automated lubrication systems with intelligent monitoring, robotic parts replacement for routine components, drone-based equipment inspection and analysis, and remote diagnostic capabilities through augmented reality interfaces. CPQ systems must evolve to price and coordinate these mixed service delivery models while maintaining service quality and customer satisfaction.

Augmented reality (AR) technology is transforming field service delivery by providing technicians with real-time access to equipment documentation, expert guidance, and diagnostic information. CPQ systems integrated with AR platforms can generate service quotes that include virtual training components, remote expert consultation services, and guided repair procedures that improve service quality while reducing completion times.

These advanced technologies enable service providers to offer enhanced service packages including virtual reality training for equipment operators, augmented reality assistance during complex repairs, remote expert consultation during challenging diagnostics, and comprehensive documentation through digital service records with photographic and video evidence.

Blockchain technology offers potential applications in heavy equipment MRO including parts authenticity verification, supply chain transparency, warranty and service history tracking, and automated smart contract execution for service agreements. Future CPQ systems may integrate blockchain capabilities to provide customers with complete parts provenance information, automated warranty claim processing, and transparent service delivery documentation.

Increasing focus on environmental sustainability is driving demand for service strategies that extend equipment lifecycle, optimize resource utilization, and minimize waste generation. CPQ systems are evolving to support circular economy principles through remanufacturing program integration, sustainable parts sourcing options, equipment lifecycle optimization recommendations, and environmental impact assessment capabilities.

Future service packages may include carbon footprint analysis, sustainability performance metrics, remanufacturing and refurbishment services, and equipment recycling and disposal coordination to help customers meet environmental objectives while optimizing operational costs.

CPQ (Configure-Price-Quote) for heavy machinery MRO is specialized software that automates the complete process of configuring maintenance services, calculating accurate pricing including parts and labor costs, and generating comprehensive quotes for equipment repair, overhaul, and preventive maintenance programs. Unlike standard CPQ systems designed primarily for new equipment sales and simple product configuration, MRO CPQ handles complex aftermarket service scenarios including parts compatibility validation across multiple manufacturers, service history integration for informed maintenance recommendations, multi-vendor sourcing requirements with remanufactured and aftermarket options, regulatory compliance checking for safety and environmental standards, and integration with field service management systems for complete service delivery coordination.

Heavy machinery MRO CPQ software costs typically range from $15,000-$50,000 annually for small to medium dealers, with enterprise solutions ranging $75,000-$200,000+ depending on user count, integration complexity, and customization requirements. Implementation costs including data migration, training, and integration services typically add 50-100% of annual license fees. However, organizations typically achieve positive return on investment within 6-18 months through quote generation speed improvements of 70-85%, service revenue increases of 25-40%, and operational efficiency gains of 30-50%. Additional ROI drivers include reduced administrative overhead, improved customer satisfaction scores, increased preventive maintenance adoption rates, and reduced quote errors that eliminate costly rework.

CPQ systems reduce equipment downtime through multiple mechanisms: quote generation acceleration from days or weeks to minutes or hours enables immediate repair decision-making, automated parts compatibility checking prevents incorrect orders that delay repairs, real-time inventory visibility eliminates stockout delays by identifying alternative suppliers automatically, integration with predictive maintenance systems enables proactive service scheduling before failures occur, and mobile field service integration improves first-time fix rates by ensuring technicians have correct parts and information. Advanced maintenance strategies can reduce equipment downtime by 30-50% while lowering maintenance costs by 15-25%, allowing scheduled repairs during planned downtime rather than emergency situations that disrupt operations and increase costs.

The best CPQ software solutions for heavy equipment operations include platforms specifically designed for complex manufacturing and service environments. Key evaluation criteria include native integration with ERP and CRM systems, comprehensive parts catalog management with compatibility validation, mobile field service capabilities with offline functionality, advanced pricing engines supporting complex service scenarios, workflow automation for approvals and customer communication, and robust analytics for performance monitoring. Leading platforms like Mobileforce provide comprehensive revenue operations capabilities that unify CPQ, field service management, and customer analytics into seamless workflows designed specifically for heavy equipment operations. Advanced no-code configuration capabilities enable rapid customization without technical expertise, while industry-specific functionality for manufacturing addresses unique heavy equipment requirements including complex parts compatibility, service history integration, and regulatory compliance management. Organizations should evaluate vendors based on implementation methodology, ongoing support quality, proven success with similar heavy equipment operations, and ability to provide unified revenue operations rather than point solutions that create operational silos.

Heavy machinery MRO CPQ implementation timelines typically range from 4-8 months depending on system complexity, data quality, and integration requirements. The process includes several phases: data cleanup and standardization (1-3 months) for parts catalogs, customer records, and equipment databases, system configuration and integration (2-4 months) with existing ERP, CRM, and field service systems, user training and pilot testing (1-2 months) with select service teams and customer scenarios, and full deployment and optimization (1 month) across all users and processes. Organizations with clean data and simple integration requirements may complete implementation in 3-4 months, while those requiring extensive customization or legacy system integration may need 6-9 months. Modern platforms with proven migration methodologies can accelerate timelines through automated data migration tools, pre-built integration templates, and comprehensive change management programs that ensure rapid user adoption and minimize business disruption during transition periods.

Advanced CPQ systems manage complex parts compatibility through sophisticated database structures that encode equipment specifications, component relationships, and validation rules. These systems maintain detailed databases of equipment models with serial number ranges, software versions, and regional variations, component compatibility matrices showing valid and invalid combinations, supplier information including OEM, aftermarket, and remanufactured options, regulatory compliance requirements for different applications and geographic markets, and substitution recommendations when preferred parts are unavailable. When service advisors configure maintenance quotes, the system automatically validates selections against these rules, checks real-time inventory across multiple warehouse locations, suggests optimal alternatives based on availability and cost, and prevents configurations that could compromise safety or performance. Integration with supplier systems provides real-time pricing updates and delivery timeframes.

Training requirements for heavy machinery MRO CPQ systems typically include role-specific programs addressing different user needs: service advisors receive training on quote generation, customer consultation, and system navigation (typically 2-3 days), field technicians learn mobile application usage, work order integration, and offline functionality (1-2 days), managers focus on reporting, analytics, and system administration (1-2 days), and administrators learn system configuration, user management, and integration maintenance (3-5 days). Modern platforms emphasize intuitive interfaces that minimize learning curves through guided workflows and contextual help. Ongoing support typically includes regular refresher training, system updates and new feature introduction, performance optimization assistance, and technical support for integration issues. Successful implementations often establish internal champion programs where experienced users assist colleagues with system questions and process improvements.

MRO CPQ platforms provide comprehensive integration capabilities with existing business systems through multiple connection methods. ERP system integration enables real-time inventory visibility, automated procurement workflows, parts pricing synchronization, and financial data coordination for billing and revenue recognition. CRM integration ensures customer data consistency, service history access, equipment asset information, and unified communication tracking across all customer touchpoints. Field service management integration coordinates work order generation, technician scheduling, mobile application synchronization, and service completion reporting. Advanced platforms offer no-code integration capabilities that simplify setup and maintenance through pre-built connectors, API-based connectivity, and standard protocol support. Integration architecture typically supports bidirectional data synchronization to maintain consistency across all platforms while avoiding duplicate data entry and ensuring real-time information updates.