Connecting the shop floor to the sales floor with intelligent CPQ

Manufacturing companies lose millions annually due to disconnected spare-parts catalogs, predictive maintenance systems, and quoting processes. When equipment fails, technicians scramble through thousands of SKUs while maintenance teams work from separate systems, creating delays that cost $50,000 per hour of unplanned downtime according to Aberdeen Group research. The solution? Integrating CPQ (Configure, Price, Quote) platforms with spare-parts catalogs and predictive maintenance triggers creates a unified workflow that reduces quote turnaround by 50%, increases preventive maintenance attach rates by 20%, and cuts equipment downtime by up to 12%.

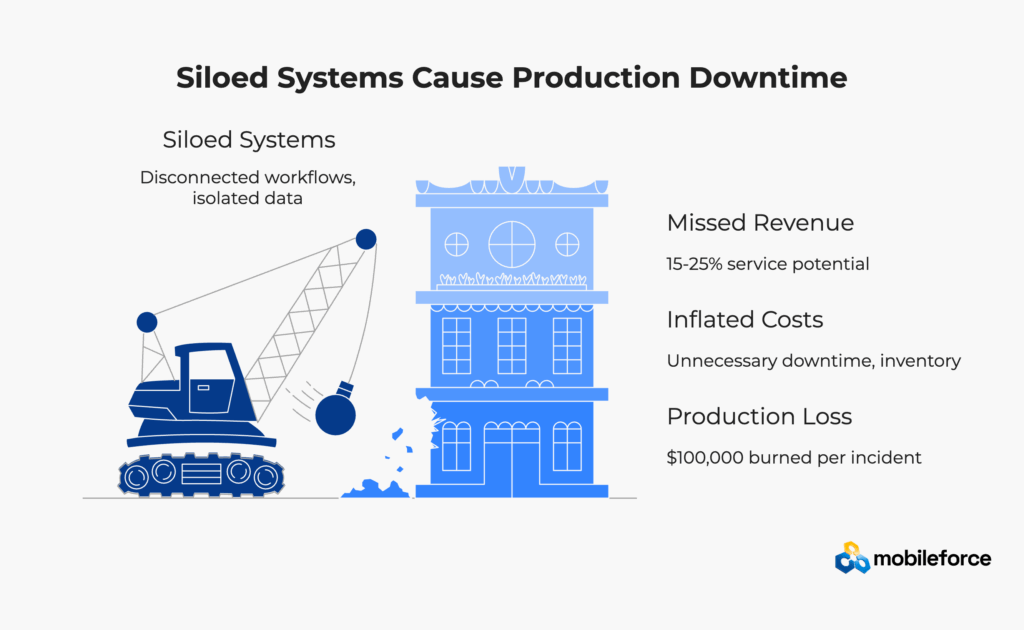

Picture this: a critical production line grinds to a halt at 2 AM. The sensor data screamed warnings for weeks, but those alerts lived in one system while the spare-parts catalog sat in another, and the service quoting happened through spreadsheets. By the time technicians identified the right part, created a quote, and scheduled maintenance, the company had burned through $100,000 in lost production—a scenario that costs U.S. manufacturers over $50 billion annually in unplanned downtime according to Deloitte analysis.

This scenario plays out daily across manufacturing facilities worldwide, but it doesn’t have to. The culprit isn’t broken equipment—it’s broken processes created by siloed systems that traditional CPQ vendors never designed to work together. When spare-parts catalogs, predictive maintenance systems, and quoting workflows operate in isolation, even the most sophisticated manufacturers face unnecessary downtime, inflated inventory costs, and missed aftermarket revenue opportunities worth an estimated 15-25% of total service potential.

While most CPQ platforms focus on new product sales, the manufacturing MRO (maintenance, repair, and operations) landscape demands a fundamentally different approach. Companies need systems that connect equipment condition data directly to parts catalogs and service quoting, creating seamless workflows from sensor alert to technician dispatch. This integration transforms reactive maintenance into proactive revenue generation while protecting equipment uptime—a critical factor when considering that every hour of downtime in automotive manufacturing costs approximately $1.3 million according to McKinsey research.

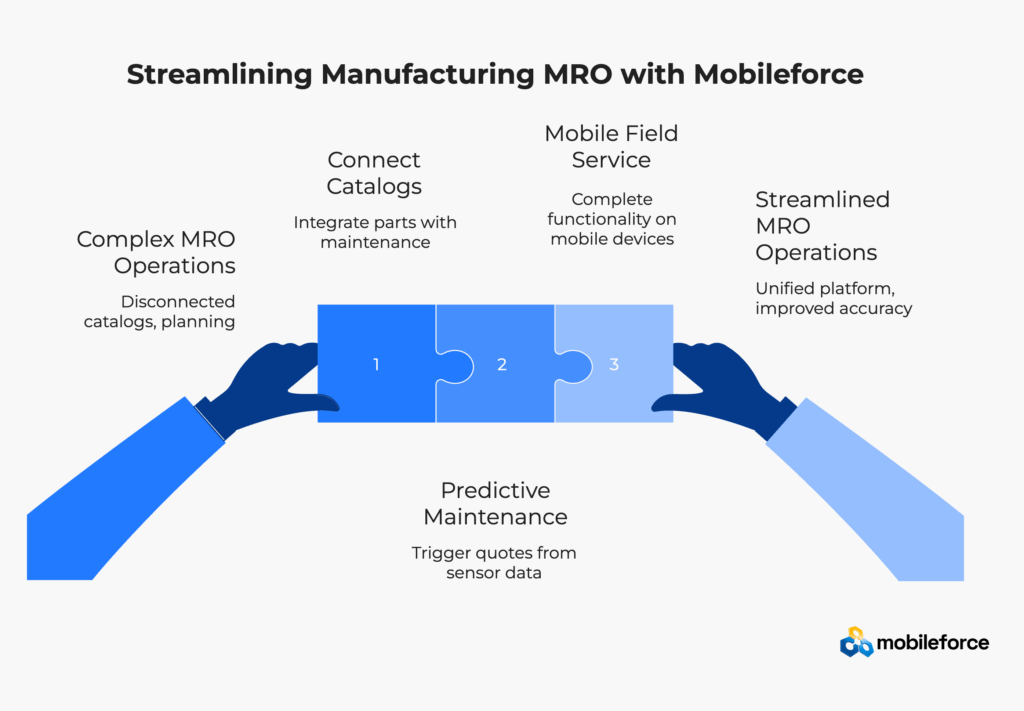

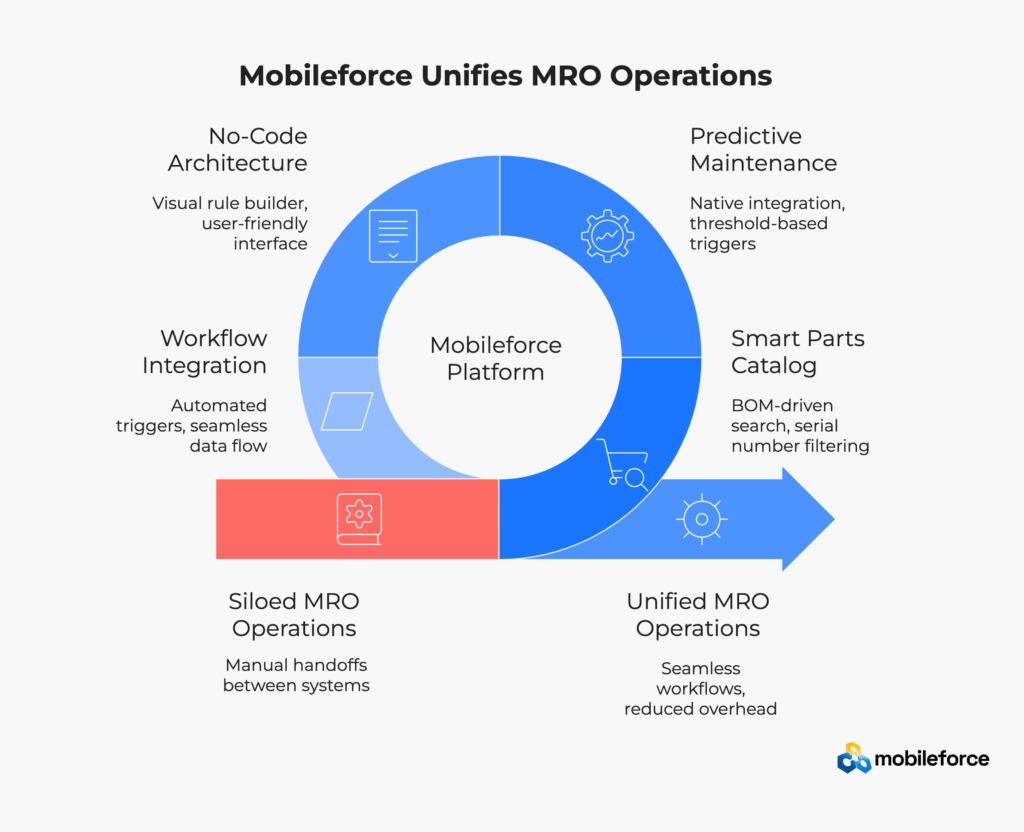

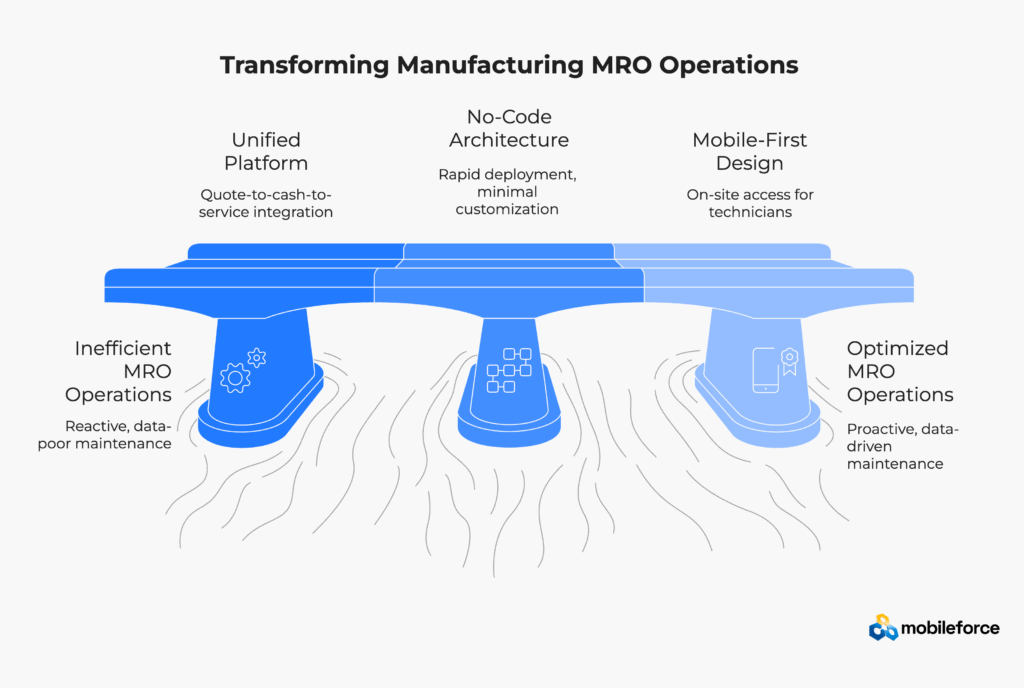

This is precisely why Mobileforce built the industry’s only unified quote-to-cash-to-service platform specifically designed for manufacturing MRO environments. Unlike traditional CPQ vendors who retrofit product sales tools for service applications, Mobileforce’s no-code platform natively integrates spare-parts catalogs with field service management and predictive maintenance workflows, eliminating the disconnects that cost manufacturers millions annually.

Manufacturing operations generate staggering complexity around spare parts management and maintenance planning. A typical automotive plant manages over 40,000 unique SKUs across production equipment, with each machine requiring specific part numbers, serial-matched components, and variant configurations.

Traditional spare-parts catalogs and inventory management systems weren’t designed for this scale. Most legacy systems struggle with basic functions like exploded view navigation, BOM-driven search capabilities, and real-time inventory visibility. Maintenance technicians report spending hours searching through catalogs to find the right part, often settling for “close enough” alternatives that create future reliability issues.

Predictive maintenance systems add another layer of complexity. Modern manufacturing relies heavily on condition-based monitoring using vibration sensors, thermal imaging, and oil analysis to predict equipment failures. These IoT systems generate thousands of data points daily, but most manufacturers struggle to translate sensor alerts into actionable maintenance quotes and parts orders.

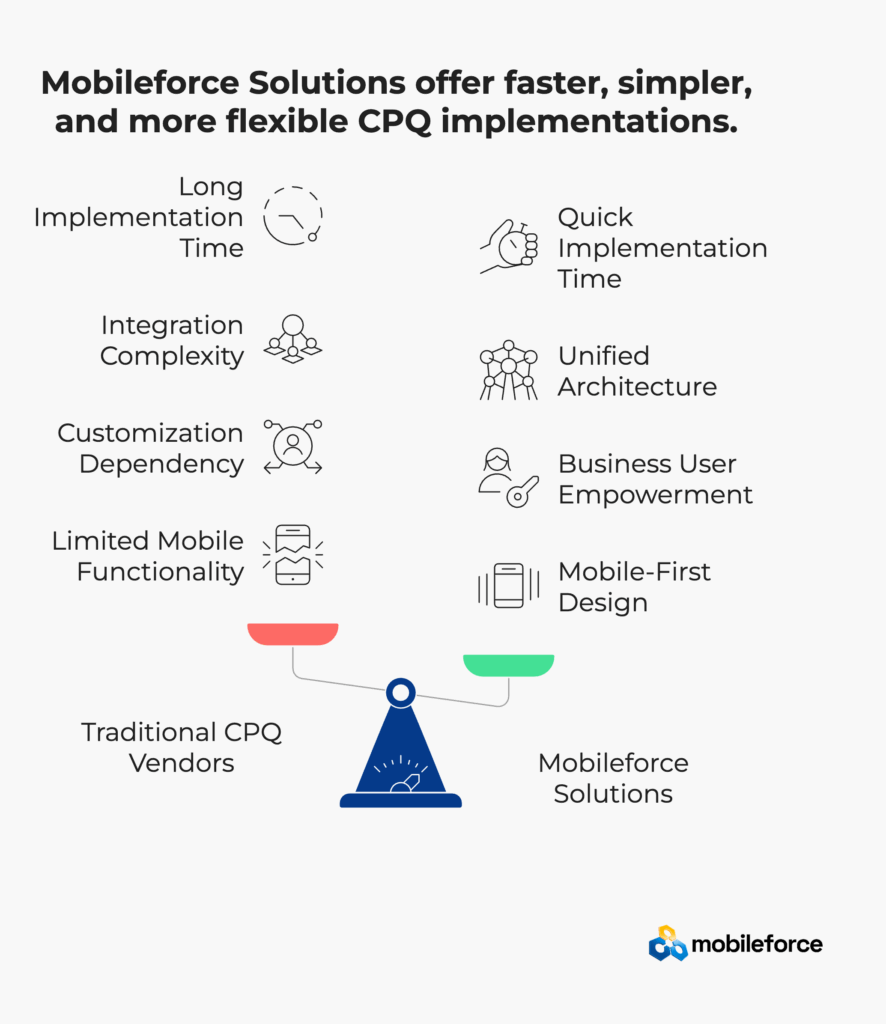

Traditional CPQ platforms built for new product sales struggle with MRO requirements including thousands of SKUs, exploded view navigation, serial-specific compatibility, and real-time inventory synchronization. Most require extensive customization just to handle basic BOM relationships, often taking 12-18 months to implement.

More critically, these platforms never anticipated predictive maintenance integration or mobile field service capabilities. The result is typically expensive custom development, brittle integrations, and ongoing maintenance headaches.

Mobileforce built the industry’s first unified quote-to-cash-to-service platform specifically for manufacturing MRO challenges. The no-code architecture eliminates customization complexity, reducing implementation timelines from 12-18 months to 8-12 weeks. The mobile-first design ensures field technicians have complete functionality on smartphones and tablets, including offline capabilities.

When Mobileforce’s platform connects spare-parts catalogs directly to predictive maintenance triggers and CPQ workflows, the transformation becomes immediately visible. Quote accuracy improves dramatically because maintenance technicians access complete equipment histories and pre-validated parts lists from a unified interface, reducing parts return rates from 15-20% down to 3-5%.

Service attach rates increase substantially as Mobileforce’s intelligent recommendation engine automatically suggests preventive maintenance opportunities based on real-time equipment condition data, increasing average transaction values by 25-40%.

Customer satisfaction improves through comprehensive quotes with detailed maintenance explanations, compatibility guarantees, and transparent service agreements. The platform’s self-service customer portals provide real-time visibility into maintenance schedules and equipment health.

Ready to see how Mobileforce’s unified platform eliminates these MRO challenges? Schedule a demo to explore how our quote-to-cash-to-service solution connects spare-parts catalogs with predictive maintenance workflows in ways traditional CPQ vendors simply can’t match.

While traditional CPQ vendors struggle with basic catalog functionality, Mobileforce’s platform was designed from the ground up to handle manufacturing spare parts complexity. The system supports interactive exploded view navigation and BOM-driven search functionality that ensures technicians find exact manufacturer specifications rather than generic alternatives.

When integrated with equipment serial numbers and configuration data, the system automatically filters catalog results to show only compatible parts for specific machine configurations, preventing costly compatibility mistakes while reducing catalog navigation time from hours to minutes.

Unlike legacy systems requiring expensive middleware, Mobileforce’s native real-time synchronization connects directly with ERP platforms and supplier networks to show current availability and accurate lead times. The platform’s automated data validation tools maintain accuracy over time while reducing manual maintenance overhead.

Where traditional CPQ vendors require expensive custom development to connect with condition monitoring systems, Mobileforce’s platform includes native predictive maintenance integration. The system processes vibration analysis, thermal imaging, and oil analysis to identify potential equipment failures before they occur.

Mobileforce’s threshold-based triggers and machine learning algorithms automatically initiate quoting workflows when equipment health indicators exceed predetermined limits. The platform’s CMMS integration enables comprehensive maintenance planning that considers both real-time condition data and time-based preventive maintenance intervals.

The greatest differentiator between Mobileforce and traditional CPQ vendors lies in the no-code architecture that eliminates customization complexity. While competitors require months of expensive consultant time to configure basic pricing rules, Mobileforce’s visual rule builder enables maintenance managers to set up complex workflows in hours, not months.

Traditional CPQ vendors lock customers into rigid configurations requiring IT intervention for modifications. Mobileforce’s business-user-friendly interface ensures maintenance teams can adapt quickly without waiting for development resources.

The platform’s native field service management integration creates seamless workflows from equipment condition alerts through quote generation to technician dispatch. Most importantly, Mobileforce’s mobile-first design ensures field technicians have complete functionality including offline capabilities, while traditional vendors offer mobile apps as afterthoughts with limited functionality.

The ultimate goal involves creating seamless workflows that eliminate manual handoffs between systems. When condition monitoring identifies potential equipment issues, the integrated platform should automatically:

This level of integration requires robust API connectivity between previously siloed systems. Leading manufacturers report 30-40% reduction in administrative overhead when implementing unified workflows that eliminate duplicate data entry and manual coordination tasks. Mobileforce’s no-code approach to integration makes these connections possible without extensive IT development, enabling business users to configure workflows and rules directly.

System Component | Traditional Approach | Integrated Approach | Performance Impact |

Parts Identification | Manual catalog search across multiple systems | Automated BOM matching with serial number validation | 75% time reduction |

Maintenance Triggers | Reactive failure response after equipment stops | Predictive condition alerts with automated workflows | 60% downtime reduction |

Quote Generation | Separate pricing systems requiring manual coordination | Unified CPQ workflow with real-time data | 50% faster turnaround |

Service Scheduling | Manual coordination between multiple departments | Automated dispatch with field service integration | 40% efficiency gain |

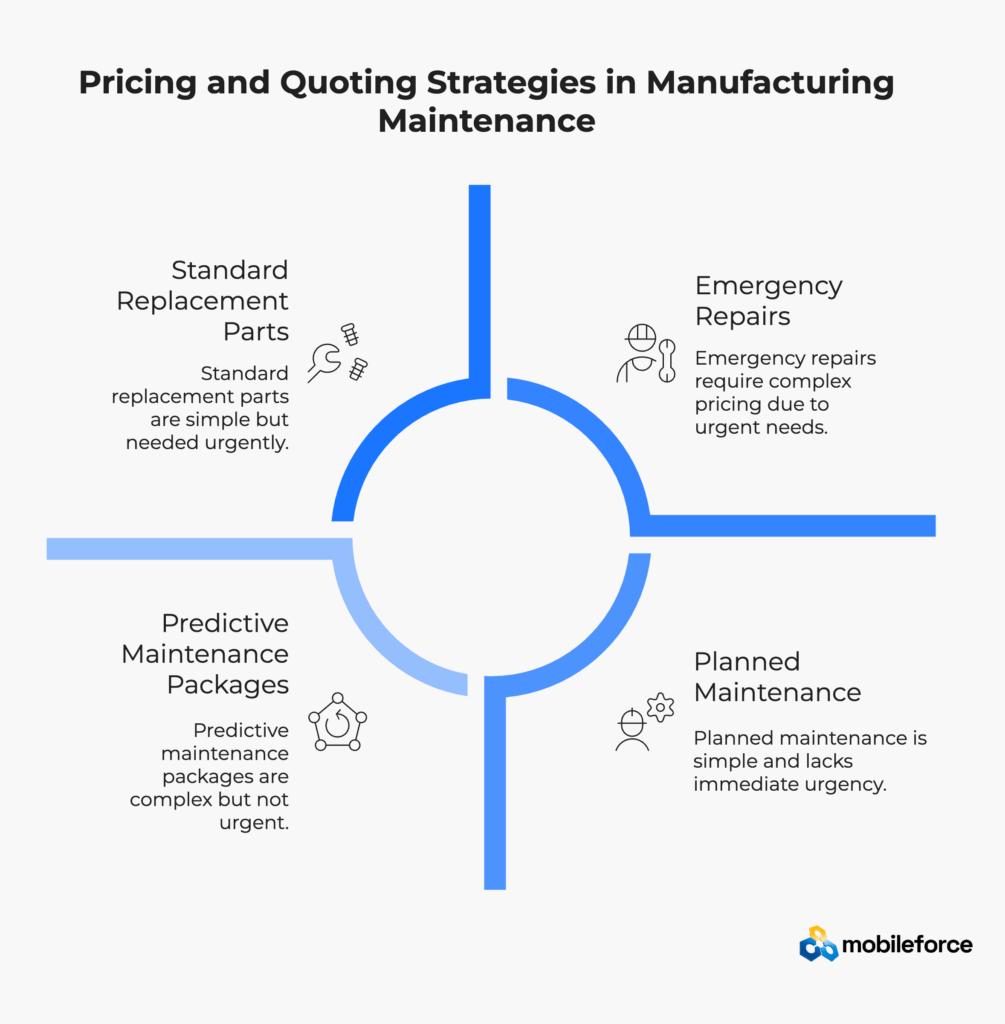

Sophisticated manufacturing operations require pricing logic that reflects the urgency and complexity of different maintenance scenarios. Emergency repairs command premium pricing due to after-hours labor, expedited parts delivery, and production impact mitigation. Conversely, planned maintenance during scheduled downtime allows for standard pricing and bulk purchasing advantages.

Rule-based pricing engines enable automatic quote adjustments based on multiple factors. When vibration sensors indicate bearing wear approaching critical thresholds, the system might quote standard replacement parts at regular pricing. But if those same sensors show imminent failure during peak production periods, pricing automatically adjusts to reflect emergency service premiums and expedited delivery costs.

Parts kit bundling becomes particularly valuable in predictive maintenance scenarios. Instead of quoting individual components, technicians can present complete repair packages that include primary parts, related consumables, and complementary maintenance items. A pump rebuild quote might automatically include seals, gaskets, lubricants, and alignment services in a single package price.

Condition severity affects parts recommendations as well as pricing. Minor wear patterns might trigger quotes for preventive component replacement, while severe degradation requires comprehensive overhaul packages. The system should automatically escalate parts recommendations based on sensor data severity and equipment criticality.

Long-term maintenance agreements require sophisticated pricing models that balance customer value with service profitability. Annual maintenance contracts provide predictable revenue streams while giving customers budget certainty and guaranteed service availability. However, pricing these agreements requires careful analysis of equipment failure patterns, service costs, and competitive market rates.

Tiered pricing structures accommodate different customer risk tolerances and service requirements. Basic agreements might include scheduled inspections and minor adjustments, while comprehensive packages cover all parts, labor, and emergency response. The key lies in clearly defining service scope while maintaining pricing transparency.

Escalation clauses protect against inflation and unexpected cost increases over multi-year terms. Rather than fixed pricing that becomes unprofitable, agreements should include annual adjustment mechanisms tied to labor rates, parts costs, or industry indices.

Performance guarantees differentiate premium service offerings from basic maintenance contracts. Customers pay higher rates for guaranteed uptime levels, rapid response times, or equipment availability commitments. These premium services require sophisticated resource planning but generate substantially higher margins.

Integrated systems excel at identifying revenue opportunities that technicians might otherwise miss. When quoting bearing replacements, the system can automatically suggest complementary maintenance activities like alignment checks, lubrication system upgrades, or vibration monitoring enhancements.

Equipment lifecycle data enables predictive upselling based on maintenance patterns and failure histories. Customers approaching equipment end-of-life receive proactive quotes for replacement options, upgrade packages, or extended service agreements that maximize remaining asset value.

Seasonal maintenance bundling takes advantage of planned downtime periods to combine multiple maintenance activities. Rather than separate quotes for different systems, customers receive comprehensive shutdown packages that minimize production impact while maximizing maintenance efficiency.

Training and documentation services provide additional revenue streams particularly valuable for complex equipment. Customers purchasing major components receive bundled training quotes for operators and maintenance staff, ensuring proper equipment utilization and extending component life.

Manufacturing MRO operations often involve significant price pressure, particularly during emergency situations when customers feel vulnerable. Automated approval workflows protect margins by escalating heavily discounted quotes while enabling field technicians to respond quickly to customer needs.

Threshold-based approvals route quotes based on discount levels, total values, or margin percentages. Standard maintenance quotes might automatically approve within predetermined parameters, while emergency repairs or large projects require management review regardless of discount levels.

Competitive intelligence integration helps maintain market-appropriate pricing while protecting profitability. The system might flag quotes that deviate significantly from historical pricing patterns or market benchmarks, enabling managers to investigate competitive pressures or cost structure changes.

Customer-specific pricing agreements require sophisticated rule management to ensure consistent application across multiple locations and service scenarios. Large customers with negotiated rates should receive automatic pricing adjustments without manual intervention, while maintaining audit trails for contract compliance verification.

Transform your maintenance quoting process today. Book a consultation to discover how Mobileforce’s unified platform eliminates the integration challenges and customization complexity that plague traditional CPQ vendors.

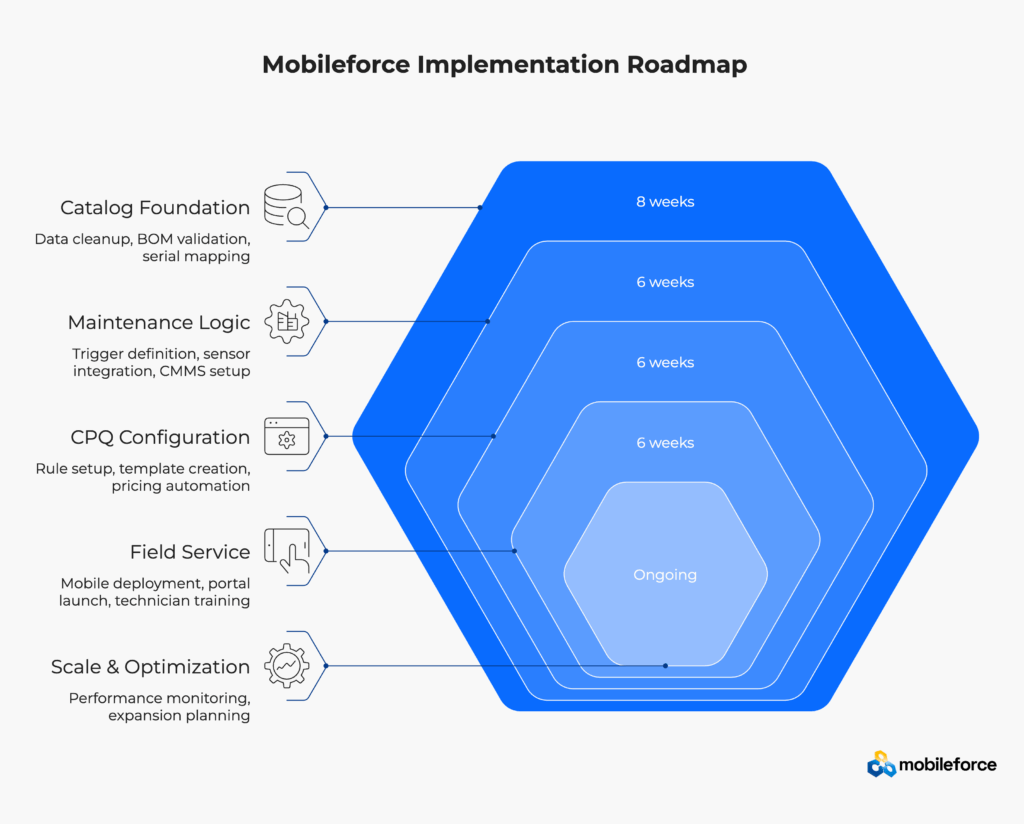

While traditional CPQ vendors require extensive customization projects lasting 12-18 months, Mobileforce’s no-code architecture and pre-built manufacturing MRO functionality enables complete implementation in 8-12 weeks. This dramatic timeline reduction stems from the platform’s purpose-built design that eliminates the custom development required by legacy vendors.

The implementation approach reflects Mobileforce’s understanding of manufacturing operations. Rather than forcing customers to adapt their processes to rigid software limitations, the platform’s flexible configuration accommodates existing workflows while introducing efficiency improvements that generate immediate value.

Success starts with clean, accurate spare-parts data. Most manufacturers underestimate the effort required to consolidate multiple catalogs, standardize part numbering systems, and establish accurate BOM relationships. This foundational work typically consumes 60-70% of total implementation effort but determines long-term system effectiveness.

Parts master cleanup involves identifying duplicate entries, standardizing descriptions, and validating manufacturer specifications. Many companies discover they’ve been stocking multiple part numbers for identical components, creating unnecessary inventory costs and supplier complexity. Consolidating these duplicates can reduce catalog size by 20-30% while improving purchasing efficiency.

BOM validation ensures accurate parent-child relationships between assemblies and components. This process requires mechanical knowledge and manufacturer documentation review, making it time-intensive but critically important. Inaccurate BOMs lead to wrong parts quotes, customer dissatisfaction, and technician productivity losses.

Serial number traceability implementation enables precise parts matching for specific equipment configurations. Modern manufacturing equipment often requires exact part specifications based on production dates, software versions, or configuration options. Without this traceability, technicians resort to physical inspection or trial-and-error approaches that waste time and create errors.

Parallel to catalog cleanup, teams must define the business rules that translate equipment condition data into maintenance recommendations. This process requires collaboration between maintenance engineers, operations staff, and equipment manufacturers to establish meaningful thresholds and appropriate responses.

Equipment criticality assessment forms the foundation for trigger logic. Production-critical equipment requires aggressive monitoring and immediate response to any condition degradation, while support systems might tolerate longer intervention timelines. These criticality ratings directly influence alert thresholds and automated quote generation rules.

Sensor integration planning determines which data streams feed into the automated decision engine. Vibration analysis, thermal monitoring, and fluid analysis each provide different insights requiring specific interpretation logic. The system must correlate multiple sensor inputs to provide comprehensive equipment health assessments.

CMMS integration ensures maintenance triggers consider both condition data and scheduled maintenance requirements. The optimal approach combines predictive alerts with planned maintenance windows to minimize production disruptions while maximizing maintenance efficiency.

Unlike traditional CPQ vendors that require months of complex configuration, Mobileforce’s visual rule builder enables rapid setup of pricing logic, approval workflows, and integration triggers. The platform’s pre-built templates for common maintenance scenarios accelerate deployment while ensuring consistency across quotes and proposals.

Mobileforce’s no-code approach means maintenance managers can configure complex business rules without technical programming skills, eliminating the consultant dependency that plagues traditional implementations. The platform’s intuitive interface enables rapid iteration based on pilot feedback, ensuring the final configuration matches operational requirements.

Integration testing validates seamless data flows between Mobileforce and existing systems including CMMS, ERP, and inventory management platforms. The platform’s native integration capabilities eliminate the middleware complexity that traditional vendors require, reducing implementation risk while ensuring reliable long-term operation.

Mobile technician enablement extends CPQ capabilities to field personnel, allowing onsite quote generation and real-time parts verification. Modern technicians expect mobile-first interfaces that provide complete functionality without requiring laptop computers or complex navigation. Solutions like Mobileforce prioritize mobile usability with touch-optimized interfaces and offline capabilities that ensure productivity regardless of connectivity conditions.

Customer portal development enables self-service quote requests and maintenance scheduling for routine activities. Many customers prefer initiating standard maintenance requests through web portals rather than phone calls, particularly for non-emergency activities that can be scheduled in advance.

Workflow automation connects quote approval to work order generation, parts ordering, and technician dispatch. This integration eliminates manual handoffs that create delays and communication errors while providing complete visibility into maintenance request status.

Training programs ensure technicians and customers can effectively utilize new capabilities. Even excellent systems fail without proper user adoption, making comprehensive training essential for implementation success.

Performance monitoring identifies opportunities for rule refinement, process improvement, and capability expansion. Key metrics include quote turnaround time, first-time fix rates, parts return percentages, and customer satisfaction scores.

Rule optimization based on historical data improves prediction accuracy and reduces false alerts. Machine learning algorithms can identify subtle patterns that improve maintenance timing and parts recommendations while reducing unnecessary interventions.

Capability expansion to additional equipment types, facility locations, or service offerings multiplies initial implementation investments. Most manufacturers find that successful pilots generate enthusiasm for broader deployment across their operations.

Continuous improvement processes ensure the system evolves with changing business requirements, new equipment additions, and market conditions. Regular review cycles identify optimization opportunities while maintaining system performance and user satisfaction.

Implementation Phase | Duration | Key Activities | Success Metrics | Tools & Resources |

Catalog Foundation | 8 weeks | Data cleanup, BOM validation, serial mapping | 95% part accuracy | Data validation tools, catalog management |

Maintenance Logic | 6 weeks | Trigger definition, sensor integration, CMMS setup | 80% alert relevance | IoT platforms, condition monitoring |

CPQ Configuration | 6 weeks | Rule setup, template creation, pricing automation | <24hr quote turnaround | No-code rule builders, workflow engines |

Field Service Enablement | 6 weeks | Mobile deployment, portal launch, technician training | 90% user adoption | Mobile apps, self-service portals |

Scale & Optimization | Ongoing | Performance monitoring, expansion planning | 15% efficiency gains | Analytics dashboards, KPI tracking |

Quote turnaround time provides the most immediate indicator of system effectiveness. Leading manufacturers target same-day turnaround for standard maintenance quotes and 4-hour response for emergency situations. Industry benchmarks show top-performing organizations achieve 60% faster quote generation compared to traditional manual processes.

First-time fix rates measure technician effectiveness and parts accuracy. When technicians arrive with correct parts and complete maintenance procedures during initial visits, customer satisfaction increases while service costs decrease. Target rates should exceed 85% for scheduled maintenance and 70% for emergency responses.

Parts return rates indicate catalog accuracy and quote precision. Excessive returns signal data quality problems, inadequate part specifications, or insufficient technician training. Best-in-class operations maintain return rates below 5% for standard maintenance parts.

Preventive maintenance attach rates demonstrate the system’s ability to identify and sell proactive maintenance opportunities. When customers accept bundled preventive services alongside reactive repairs, both parties benefit through reduced future failures and more predictable maintenance costs. Target attach rates should reach 25-30% for emergency service calls.

Service contract renewal rates reflect customer satisfaction with maintenance quality and value proposition. High-performing manufacturers achieve renewal rates exceeding 90% for multi-year agreements, indicating strong customer relationships and competitive service delivery.

Equipment uptime improvements provide the most compelling ROI justification for integrated systems. Each percentage point of uptime improvement can generate hundreds of thousands of dollars in additional production value for critical manufacturing equipment. McKinsey research indicates predictive maintenance can reduce unplanned downtime by 30-50%.

Inventory turnover for critical spares measures supply chain efficiency improvements. Better demand prediction and automated ordering reduce inventory holding costs while maintaining service levels. Target improvements range from 15-25% reduction in average inventory levels.

Average deal size growth demonstrates successful upselling and service bundling. When technicians consistently identify and sell complementary maintenance activities, both revenue per customer and customer lifetime value increase substantially.

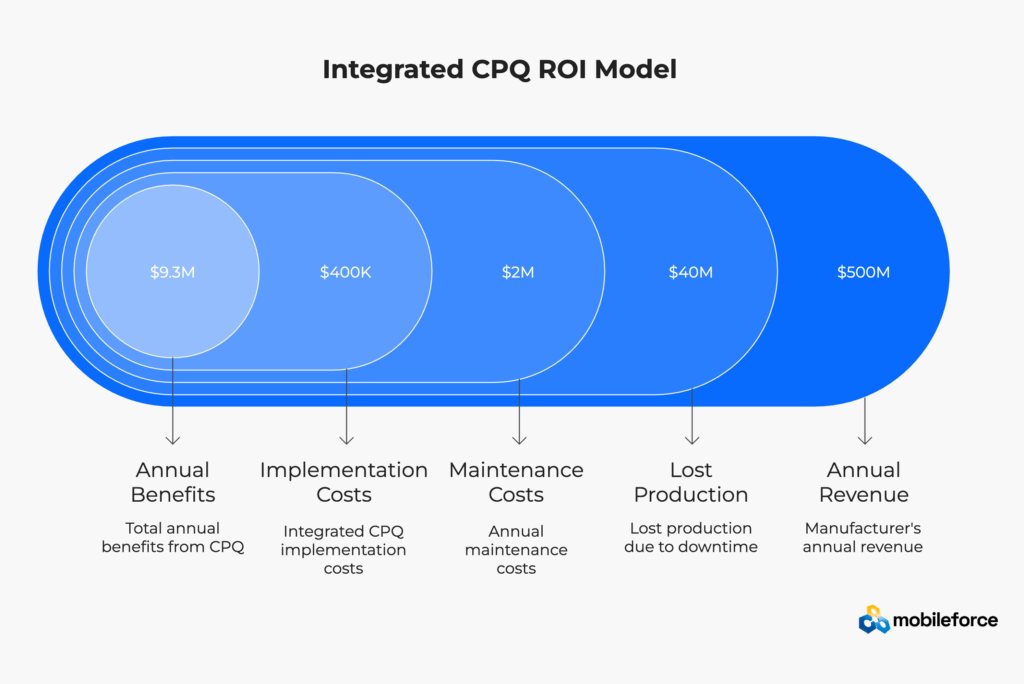

Consider a mid-size manufacturer with $500M annual revenue and 200 pieces of critical equipment. Current maintenance costs average $2M annually with 8% unplanned downtime causing $40M in lost production annually.

Implementing integrated CPQ with predictive maintenance and spare-parts catalogs typically costs $300-500K including software, implementation, and training. Conservative benefits include:

Total annual benefits of $9.3M against $400K implementation costs provide 23:1 ROI with 2-month payback period. Even achieving half these benefits generates compelling financial returns.

Predictive accuracy metrics measure the system’s ability to identify actual equipment failures before they occur. False positive rates above 30% indicate overly sensitive monitoring, while false negative rates above 10% suggest insufficient sensitivity. Continuous calibration optimizes these trade-offs.

Customer satisfaction scores track service quality improvements from integrated operations. Net Promoter Scores should improve as quote accuracy increases, response times decrease, and maintenance becomes more proactive rather than reactive.

Competitive benchmarking against industry standards validates performance improvements and identifies additional optimization opportunities. Leading manufacturers share anonymized performance data through industry associations to establish realistic targets and best practices.

Maintenance cost per unit of production provides normalized comparison metrics across different facility types and production volumes. This metric helps identify top-performing locations and scaling opportunities for successful practices.

Ready to achieve these performance improvements in your organization? Schedule a demo to see how Mobileforce’s integrated platform drives measurable ROI through connected spare-parts catalogs and predictive maintenance workflows.

A global automotive parts manufacturer operating 12 facilities across North America had spent 18 months attempting to implement a traditional CPQ solution from a major vendor. Despite investing over $800,000 in consulting fees, the project remained stalled due to integration complexities, customization requirements, and mobile functionality limitations that the vendor couldn’t resolve.

The manufacturer’s challenges exemplified the problems with traditional CPQ approaches: eight separate spare-parts catalogs across different divisions, over 15,000 unique SKUs for production equipment, and completely manual quoting processes that averaged 3-5 days for complex maintenance proposals. Their existing predictive maintenance investment wasn’t generating expected returns because the traditional CPQ vendor couldn’t integrate condition monitoring data with parts catalogs and quoting workflows.

Field technicians spent 40% of their time on administrative tasks rather than actual maintenance work due to the disconnected systems. Quote generation required multiple phone calls, email exchanges, and manual parts lookups across siloed platforms. Emergency repairs became even more problematic, often requiring 24-48 hours just to generate accurate quotes for critical equipment failures.

After terminating their relationship with the traditional vendor, the manufacturer selected Mobileforce based on the platform’s proven ability to handle manufacturing MRO complexity without extensive customization. The unified quote-to-cash-to-service architecture eliminated the integration challenges that had stalled their previous implementation.

Mobileforce’s implementation team completed the entire deployment in 10 weeks—compared to the 18+ months wasted with the traditional vendor. The no-code configuration enabled the manufacturer’s maintenance team to set up complex pricing rules and approval workflows without requiring expensive consultants or IT development resources.

The platform’s native mobile functionality provided immediate value for field technicians who could generate comprehensive quotes onsite using tablets or smartphones. Unlike the traditional vendor’s limited mobile app, Mobileforce’s offline capabilities ensured productivity even in areas with poor connectivity—a common challenge in industrial environments.

Spare-parts catalog consolidation eliminated duplicate entries and standardized part numbering across all facilities using Mobileforce’s built-in data management tools. The unified catalog included exploded view diagrams, manufacturer specifications, and cross-reference tables that helped technicians identify correct components quickly and confidently.

The manufacturer chose a phased implementation approach starting with their highest-volume facility before expanding to other locations. Phase one focused on catalog cleanup and basic CPQ functionality for the 500 most commonly replaced parts.

Phase two added predictive maintenance integration for critical production equipment including injection molding machines, automated assembly lines, and quality inspection systems. Business rules development required close collaboration between maintenance engineers, operations staff, and equipment vendors.

Phase three expanded coverage to support equipment and introduced customer self-service portals for routine maintenance requests. These portals enabled customers to initiate standard maintenance activities without direct sales interaction while providing visibility into maintenance schedules and equipment status.

The complete implementation required 18 months but delivered measurable benefits within the first quarter. Early wins built organizational confidence and secured executive support for broader deployment across all facilities.

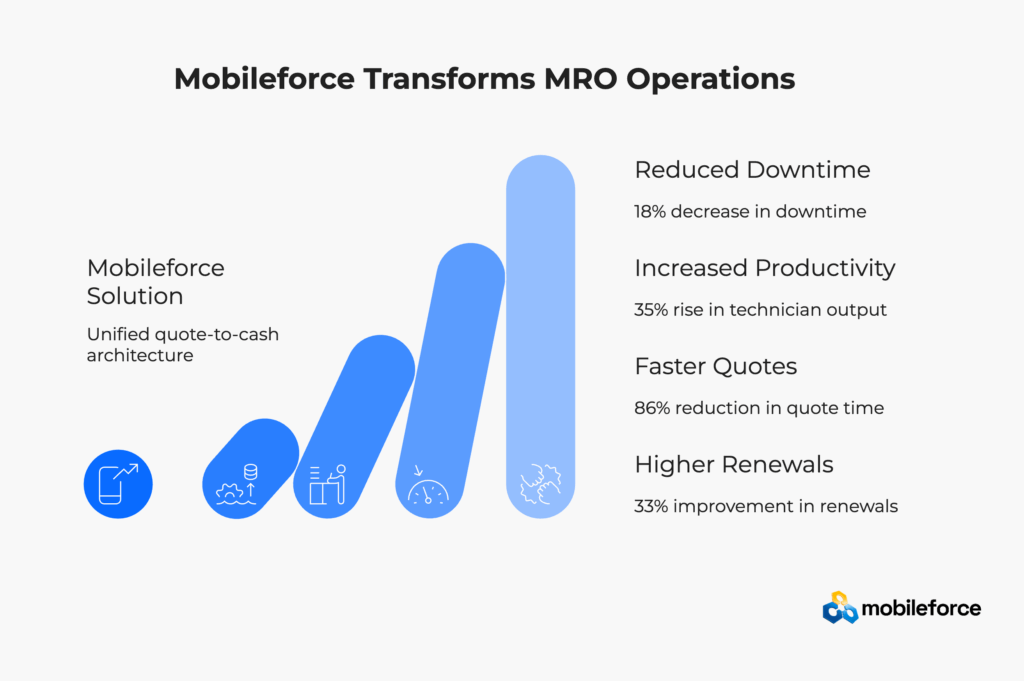

Quote turnaround time improved dramatically from an average of 3.2 days to 4.6 hours for standard maintenance quotes. Emergency quotes, previously requiring 24-48 hours, now generated within 2 hours including parts verification and technician scheduling.

Preventive maintenance attach rates increased from 12% to 31% as the integrated system automatically identified and quoted complementary maintenance activities. Customers appreciated the proactive approach and bundled pricing that provided better value than reactive maintenance.

Equipment downtime decreased by 18% through more effective predictive maintenance and faster emergency response. The financial impact exceeded $2.8M annually in avoided production losses, making this the largest single factor in the project’s ROI calculation.

Service contract renewals improved from 67% to 89% as customers experienced more reliable equipment performance and predictable maintenance costs. The revenue impact exceeded $1.2M annually while reducing sales cycle complexity for renewal negotiations.

Parts return rates dropped from 22% to 6% due to improved accuracy in parts identification and specification. This improvement reduced handling costs, customer frustration, and technician productivity losses while improving inventory management efficiency.

Field technician productivity increased by 35% as administrative tasks automated and mobile tools provided instant access to complete maintenance information. Technicians could focus on actual maintenance work rather than paperwork and parts lookup activities.

Data quality emerged as the most critical success factor. Organizations that invested adequately in catalog cleanup and BOM validation achieved substantially better results than those attempting shortcuts through this foundational work.

Change management required more attention than initially anticipated. Even excellent technology fails without proper user adoption, making comprehensive training and ongoing support essential for long-term success.

Integration complexity shouldn’t be underestimated. While modern platforms offer extensive API connectivity, achieving seamless data flow between previously siloed systems requires careful planning and thorough testing.

Continuous optimization proves essential for maximizing benefits. Initial implementations typically achieve 60-70% of potential benefits, with ongoing refinement unlocking additional value through improved rules, expanded coverage, and enhanced automation.

Performance Metric | Before Implementation | After Implementation | Improvement | Financial Impact |

Quote Turnaround Time | 3.2 days | 4.6 hours | 86% reduction | $200K annual labor savings |

Preventive Maintenance Attach Rate | 12% | 31% | 158% increase | $1.2M additional service revenue |

Equipment Downtime | 8.2% | 6.7% | 18% reduction | $2.8M avoided production losses |

Parts Return Rate | 22% | 6% | 73% reduction | $400K reduced handling costs |

Service Contract Renewals | 67% | 89% | 33% improvement | $800K retained revenue |

Technician Productivity | Baseline | +35% | 35% increase | $600K labor efficiency gains |

Traditional CPQ vendors consistently underestimate implementation complexity while overestimating their platforms’ manufacturing capabilities. These vendors approach MRO implementations as customization projects rather than deploying purpose-built functionality, leading to timeline overruns, budget bloat, and failed deployments.

Legacy vendors typically require 60-70% of project time for catalog cleanup using their inadequate data management tools, then struggle with integration challenges their platforms weren’t designed to handle. The result: 12-18 month implementations that often exceed budgets by 200-300% while delivering limited functionality.

Mobileforce Solution: Purpose-built data management tools and native manufacturing functionality enable complete implementation in 8-12 weeks. The platform’s no-code architecture eliminates customization complexity while built-in integration capabilities connect seamlessly with existing systems.

Traditional CPQ vendors treat field service management, customer portals, and predictive maintenance as separate products requiring expensive integration projects. These vendors struggle with basic requirements like mobile functionality, offline capabilities, and real-time data synchronization across multiple systems.

Most legacy implementations create brittle integration points that break with system updates, require ongoing IT maintenance, and limit future flexibility. The resulting system fragmentation perpetuates the problems manufacturers sought to solve.

Mobileforce Solution: Unified quote-to-cash-to-service architecture eliminates integration complexity by delivering CPQ, field service management, and customer portals from a single platform. Native mobile capabilities and offline functionality work reliably without custom development.

Traditional vendors require expensive consultants for basic configuration changes, creating ongoing dependency that increases total cost of ownership while reducing business agility. Simple pricing rule modifications can require weeks of development time and thousands in consulting fees.

This dependency becomes particularly problematic for manufacturing operations where business requirements change frequently based on new equipment, evolving maintenance strategies, and market conditions. Traditional vendors lock customers into rigid configurations that can’t adapt quickly.

Mobileforce Solution: No-code visual rule builder enables maintenance managers to configure complex pricing logic, approval workflows, and integration triggers without technical expertise. Business users can adapt quickly to changing requirements without waiting for IT resources or vendor support.

Traditional CPQ vendors offer mobile apps as secondary features with limited functionality, often requiring technicians to use laptops or return to offices for complex quotes. These mobile limitations force manufacturers to maintain hybrid workflows that reduce efficiency gains.

Legacy mobile apps typically lack offline capabilities, struggle with industrial connectivity conditions, and provide incomplete functionality compared to desktop versions. This approach fails to meet the real-world requirements of field maintenance operations.

Mobileforce Solution: Mobile-first architecture provides complete functionality on smartphones and tablets, including offline capabilities that work regardless of connectivity. Field technicians can generate comprehensive quotes, access complete equipment histories, and update customer records from any location.

Avoid these costly vendor mistakes. Connect with Mobileforce specialists to learn how our purpose-built manufacturing platform eliminates the implementation risks and ongoing limitations that plague traditional CPQ vendors.

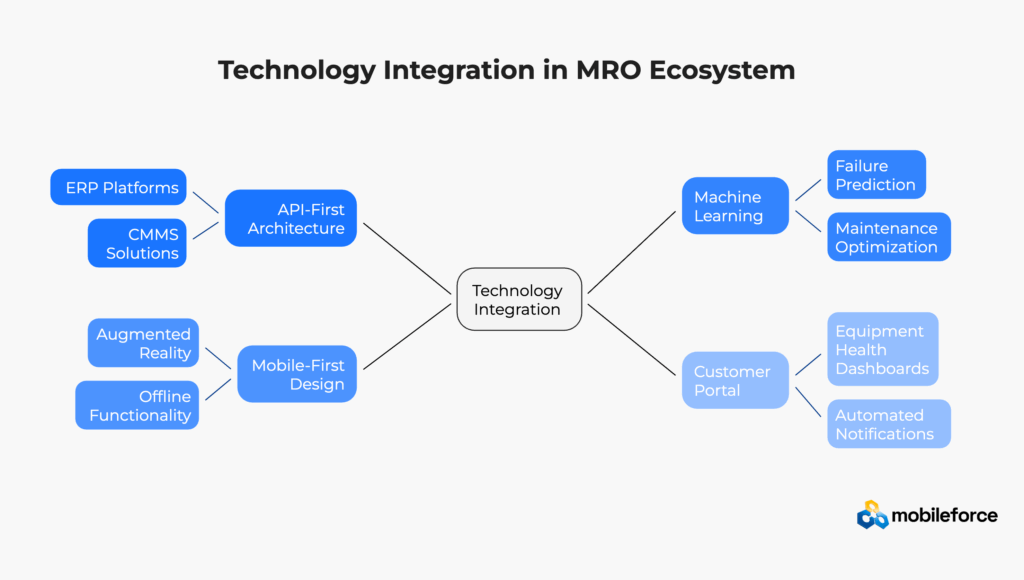

Modern manufacturing environments require platforms capable of integrating with diverse systems including ERP platforms, CMMS solutions, inventory management systems, and IoT monitoring networks. API-first architecture enables these connections without costly custom development or ongoing maintenance overhead.

Effective integration strategies prioritize real-time data synchronization over batch processing for critical information like inventory levels, equipment status, and customer contract terms. When technicians generate quotes, they need current information to ensure accuracy and avoid customer disappointment from stockouts or outdated pricing.

Industry analysis shows that organizations with well-integrated systems achieve 25-30% better operational efficiency compared to those relying on manual data transfer between platforms. The cumulative effect of eliminating duplicate data entry, reducing errors, and improving information currency creates substantial competitive advantages.

Standardized data formats and communication protocols reduce integration complexity while improving long-term maintainability. Platforms supporting industry standards like OPC-UA for equipment monitoring and REST APIs for business system integration provide greater flexibility and reduced vendor lock-in risks.

Advanced analytics capabilities transform basic condition monitoring into sophisticated failure prediction and maintenance optimization. Machine learning algorithms analyze historical failure patterns, operational conditions, and maintenance outcomes to identify subtle indicators that traditional threshold-based systems miss.

Predictive models become more accurate over time as they process additional data from equipment sensors, maintenance activities, and operational outcomes. This continuous learning enables increasingly precise failure prediction and optimal maintenance timing that maximizes equipment availability while minimizing intervention costs.

Natural language processing capabilities can analyze maintenance technician reports, equipment manuals, and failure documentation to identify patterns and recommend improved maintenance procedures. This capability proves particularly valuable for complex equipment where failure modes vary based on operating conditions and maintenance history.

Automated parts forecasting based on predictive maintenance schedules optimizes inventory levels while ensuring parts availability for planned maintenance activities. The system can automatically generate purchase orders for long-lead-time components based on predicted maintenance timing and current inventory levels.

Modern field technicians expect mobile-native interfaces that provide complete functionality without compromising usability on smartphones and tablets. Touch-optimized navigation, voice input capabilities, and offline functionality ensure productivity regardless of connectivity or environmental conditions.

Augmented reality integration enables technicians to overlay digital information onto physical equipment, providing real-time access to schematics, parts identification, and maintenance procedures. This capability reduces training requirements while improving maintenance accuracy and speed.

Photo and video capture integrated with quote generation enables technicians to document equipment conditions, share visual information with customers, and create comprehensive maintenance records. These capabilities improve communication while providing valuable data for predictive analytics improvement.

Barcode and QR code scanning streamlines parts identification and inventory management during field operations. Technicians can quickly verify part numbers, check availability, and update inventory records without manual data entry that creates errors and delays.

Self-service portals enable customers to initiate routine maintenance requests, track service progress, and access equipment documentation without direct interaction with sales or service staff. This capability reduces administrative overhead while improving customer satisfaction through increased visibility and control.

Equipment health dashboards provide customers with real-time visibility into their equipment performance, upcoming maintenance schedules, and historical trends. This transparency builds trust while encouraging proactive maintenance decisions and service contract renewals.

Automated notifications keep customers informed about maintenance schedules, parts orders, and service completion without requiring manual communication from service staff. Integration with customer communication preferences ensures notifications reach appropriate personnel through their preferred channels.

Document management capabilities provide centralized access to equipment manuals, maintenance procedures, warranty information, and service histories. This self-service access reduces support calls while ensuring customers have current information for their equipment.

Integration Component | Business Impact | Technical Requirements | Implementation Priority | Mobileforce Capability |

ERP Connectivity | Real-time inventory, pricing accuracy | REST APIs, data mapping protocols | High | Native CRM integrations with bi-directional sync |

CMMS Integration | Unified maintenance workflow automation | Database sync, trigger automation | High | Automated workflow triggers and maintenance scheduling |

IoT Sensor Networks | Predictive maintenance triggers | OPC-UA protocols, edge computing | Medium | Condition-based alert processing and parts recommendation |

Mobile Field Apps | Technician productivity, onsite quoting | Offline capability, AR support | High | Mobile-first design with offline quote generation |

Customer Portals | Self-service automation, transparency | Web APIs, notification systems | Medium | Self-service portals with real-time status updates |

Analytics Platforms | Performance optimization, reporting | Data lakes, ML algorithms | Low | Built-in analytics with customizable dashboards |

The transformation of manufacturing MRO operations represents a fundamental shift toward proactive, data-driven maintenance strategies that maximize equipment availability while optimizing service profitability. However, success depends entirely on choosing the right platform partner.

Traditional CPQ vendors struggle with manufacturing MRO requirements because their platforms were never designed for this complexity. The pattern is consistent: lengthy implementations, excessive customization costs, integration failures, and limited mobile capabilities.

Mobileforce built the industry’s only unified quote-to-cash-to-service platform specifically for manufacturing environments. The no-code architecture, mobile-first design, and native integration capabilities deliver results in weeks rather than years while providing functionality that legacy vendors claim is impossible.

The question isn’t whether to pursue MRO integration, but whether to choose a platform designed for manufacturing success or risk another failed implementation with a traditional vendor.

Transform your MRO operations with confidence. Contact Mobileforce to discover how our proven quote-to-cash-to-service platform can connect your spare-parts catalogs with predictive maintenance workflows and drive measurable improvements in equipment uptime and service profitability. Our manufacturing specialists are ready to help you avoid the pitfalls of traditional vendors while building the connected MRO ecosystem that will power your competitive advantage.

Manufacturing equipment sales CPQ focuses on configuring complex new products with multiple options, calculating volume-based pricing discounts, managing lengthy sales cycles with multiple stakeholders, and handling complex financing arrangements. The primary goal is selling new capital equipment with specifications that meet customer production requirements.

MRO quoting serves existing equipment throughout its operational lifecycle, requiring different capabilities including spare-parts catalog navigation, equipment history analysis, condition-based maintenance triggers, emergency service pricing, field service integration, and ongoing service contract management. The focus shifts from new product sales to maximizing equipment uptime and lifecycle value.

Key differences include:

MRO environments also deal with thousands of existing equipment configurations rather than standardized new product offerings, requiring access to equipment histories, maintenance schedules, parts compatibility matrices, and warranty status information that new equipment sales don’t require.

Spare-parts catalogs integrated with predictive maintenance systems enable automatic parts recommendation and quote generation based on real-time equipment condition data and failure prediction algorithms. When vibration sensors indicate potential bearing failure, IoT monitoring detects motor overheating, or oil analysis reveals contamination, the integrated system automatically identifies compatible replacement parts, required tools, and complementary maintenance items for comprehensive quotes.

The integration process works through:

BOM-driven catalog navigation ensures technicians select manufacturer-specified components rather than generic alternatives that might compromise equipment performance or void warranties. Serial number integration enables precise parts matching for specific equipment configurations, reducing compatibility errors and return rates from 15% to under 5%.

Cross-reference capabilities and recommendation engines suggest complementary maintenance activities based on parts being quoted. Bearing replacement quotes might automatically include precision alignment services, lubrication system upgrades, vibration monitoring equipment, and extended warranty coverage that address related maintenance needs and increase service revenue.

Modern mobile-enabled CPQ platforms provide complete quoting functionality through smartphones and tablets, enabling technicians to generate comprehensive quotes during equipment inspections or service calls. Offline capabilities ensure functionality regardless of connectivity limitations in industrial environments. Mobileforce’s mobile app exemplifies this capability with full offline quote generation that syncs automatically when connectivity returns.

Mobile interfaces include photo capture, barcode scanning, and voice input capabilities that streamline data collection and quote generation. Technicians can document equipment conditions, verify part numbers, and capture customer requirements without manual data entry that creates delays and errors.

Real-time integration with inventory systems, pricing databases, and customer contract terms ensures mobile quotes reflect current information. Technicians receive immediate feedback on parts availability, pricing accuracy, and service scheduling without requiring office coordination.

Digital signature capabilities enable quote approval and work authorization during onsite visits, eliminating delays associated with paper-based processes. Customers appreciate immediate service authorization that reduces equipment downtime and accelerates problem resolution.

Effective automation requires integration of multiple data streams including equipment sensor data, historical maintenance records, parts failure patterns, and operational conditions. Vibration analysis, thermal imaging, oil analysis, and electrical monitoring provide complementary insights into equipment health and failure prediction.

Equipment configuration data including serial numbers, software versions, and modification history enables precise parts recommendation and compatibility verification. This information proves critical for complex equipment where minor configuration differences affect parts selection and maintenance procedures.

Maintenance history analysis identifies patterns that improve prediction accuracy and maintenance timing optimization. Historical data reveals seasonal variations, operational impacts, and maintenance effectiveness that refine automated decision-making algorithms.

Customer contract information including service level agreements, response time requirements, and pricing terms ensures automated quotes comply with negotiated terms. Integration with customer relationship management systems provides complete context for quote generation and approval workflows.

Implementation timelines vary significantly based on catalog complexity, system integration requirements, and organizational readiness. Typical deployments require 12-18 months for comprehensive implementation across multiple facilities, though pilot deployments can achieve initial benefits within 3-4 months.

Catalog cleanup and data preparation typically consume 60-70% of total implementation time but determine long-term system effectiveness. Organizations with clean, well-organized parts data can accelerate implementation significantly compared to those requiring extensive catalog consolidation and cleanup.

Phased deployment approaches reduce risk while delivering incremental benefits throughout the implementation process. Starting with high-volume facilities or critical equipment enables organizations to demonstrate value and build user confidence before expanding to additional locations or equipment types.

Change management and training requirements often extend timelines beyond technical implementation completion. User adoption rates directly impact benefit realization, making comprehensive training and ongoing support essential for project success rather than optional activities.

Leading manufacturers report ROI ratios exceeding 15:1 within 24 months of full deployment, driven primarily by reduced equipment downtime costs, increased aftermarket service revenue, and improved operational efficiency across maintenance operations. Aberdeen Group research indicates best-in-class organizations achieve 30-50% improvement in maintenance productivity through integrated systems that eliminate manual processes and improve decision-making speed.

Financial benefits typically include:

ROI Category | Improvement Range | Annual Value (Large Manufacturer) | Payback Period |

Unplanned Downtime Reduction | 15-25% decrease | $2-8M in avoided production losses | 3-6 months |

Service Revenue Increase | 20-30% growth | $1-3M through better attach rates | 6-9 months |

Parts Cost Reduction | 10-15% savings | $500K-1.5M inventory optimization | 6-12 months |

Labor Productivity Gains | 25-35% improvement | $400K-800K efficiency gains | 9-12 months |

Contract Renewal Improvements | 15-20% increase | $600K-1.2M retained revenue | 12-18 months |

Unplanned downtime reduction provides the largest financial impact for most manufacturing operations. Each percentage point of uptime improvement generates substantial production value, particularly critical equipment in high-volume manufacturing environments. Conservative estimates show 15-20% downtime reduction within the first year of implementation, translating to millions in avoided production losses.

Service revenue increases occur through improved preventive maintenance of attach rates, more accurate competitive pricing, enhanced customer satisfaction, and better service bundling capabilities. Organizations typically see 20-30% growth in service contract renewals and 15-25% increase in average transaction values through integrated quoting systems that enable comprehensive service proposals.

Ready to achieve these performance improvements without the risks of traditional vendors? Schedule a demo to see how Mobileforce’s manufacturing-specific platform drives measurable ROI through connected spare-parts catalogs and predictive maintenance workflows.