Bridge the gap between quoting and fulfillment with seamless CPQ–ERP integration

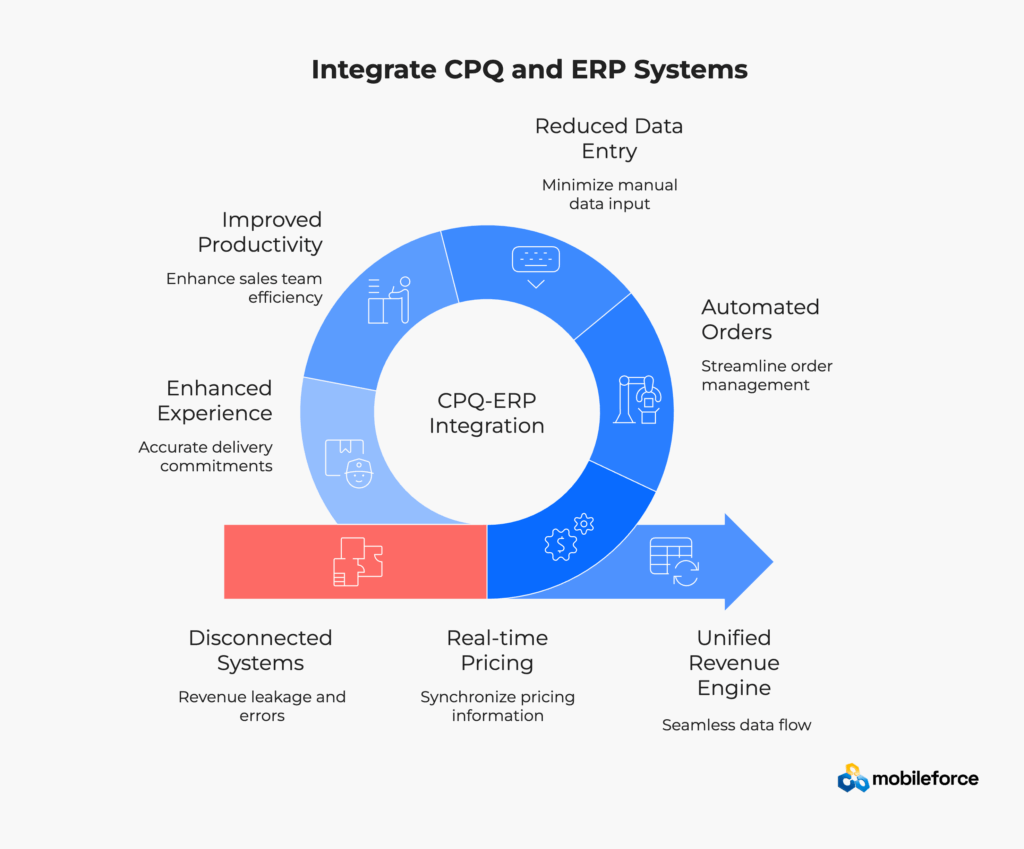

The disconnect between Configure Price Quote (CPQ) and Enterprise Resource Planning (ERP) systems costs businesses millions in pricing errors, delayed orders, and lost revenue opportunities. This comprehensive guide explores proven integration strategies, technical architecture patterns, and operational frameworks that transform fragmented quote-to-cash processes into unified revenue engines. Companies implementing proper CPQ-ERP integration typically see 40-60% reduction in quote errors and 25-35% faster order processing times. Key benefits include real-time pricing synchronization, automated order management, reduced manual data entry, improved sales productivity, and enhanced customer experience through accurate delivery commitments.

Picture this scenario: Your sales team closes a major deal worth $2.3 million. The celebration is short-lived. Three weeks later, fulfillment discovers the quoted configuration doesn’t match available inventory. The promised delivery date slips by six months. Worse yet, the pricing was based on outdated cost data, turning your profitable deal into a margin nightmare.

This isn’t fiction. According to research cited in Aberdeen Group’s CPQ implementation study, 73% of companies experience significant revenue leakage due to disconnected quoting and fulfillment systems. The root cause? CPQ and ERP systems operating in isolation, creating blind spots that compound throughout the quote-to-cash cycle.

But here’s the opportunity hiding in plain sight: Companies with integrated CPQ-ERP ecosystems report 15-20% higher win rates and 30% faster quote delivery, according to Forrester’s Configure, Price, Quote Solutions Landscape research. These organizations have cracked the code on seamless data flow between configuration logic and operational reality, enabling automated pricing updates, real-time inventory visibility, streamlined order processing, and enhanced sales team productivity.

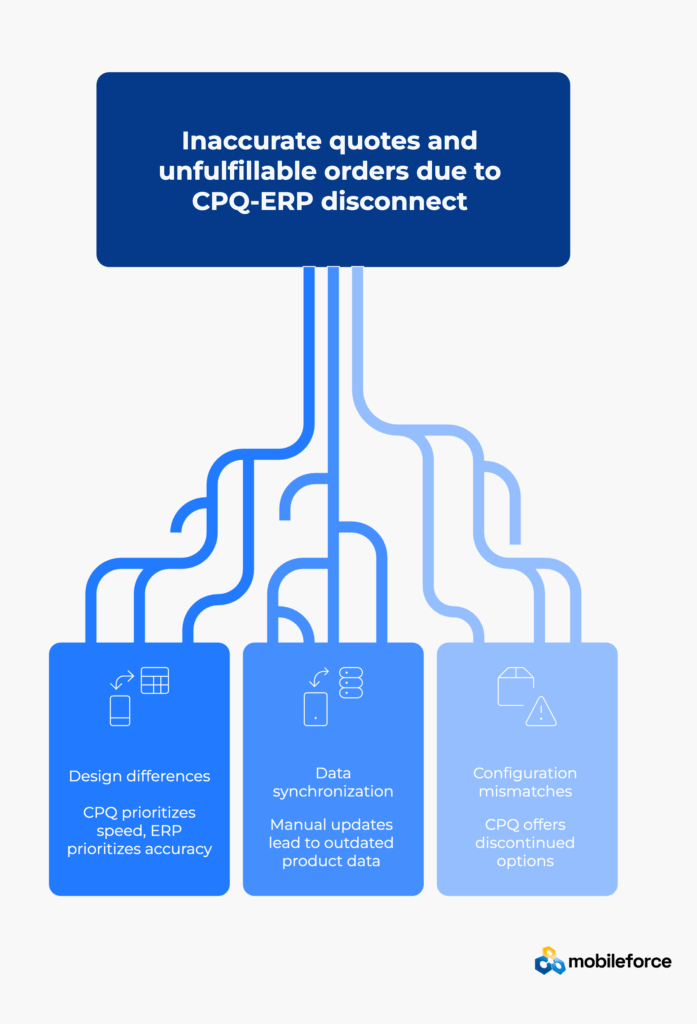

The fundamental tension between CPQ and ERP systems stems from their different design philosophies and business objectives. CPQ systems excel at handling complex configuration logic, dynamic pricing rules, discount management, and approval workflows. They’re built for speed and flexibility, enabling sales teams to generate quotes quickly while navigating intricate product catalogs, customer-specific pricing agreements, and promotional campaigns.

ERP systems, conversely, prioritize accuracy and control over operational data. They maintain the single source of truth for product master data, inventory levels, cost structures, manufacturing constraints, supplier information, and financial records. While ERP excels at operational integrity and compliance reporting, it wasn’t designed for the dynamic, customer-facing scenarios that CPQ handles daily with real-time pricing calculations and interactive product configuration.

This architectural mismatch creates predictable friction points that impact quote accuracy and order fulfillment. Product SKUs get duplicated across systems with slight variations in descriptions or specifications. Pricing rules in CPQ become outdated when cost structures change in ERP, leading to margin erosion. Configuration options remain available in CPQ long after manufacturing discontinues them in ERP, resulting in unfulfillable orders.

Consider a global manufacturing company with 50,000+ SKUs and complex bill-of-materials structures. Their sales team uses CPQ software to handle sophisticated product configurations, customer-specific pricing models, and multi-tier discount structures, but the system pulls product data that’s manually updated quarterly from ERP. During peak selling seasons, this lag results in quotes for discontinued products, pricing based on obsolete costs, and promised delivery dates that ignore current capacity constraints and supply chain disruptions.

The downstream impact ripples through the entire organization, affecting sales performance, customer satisfaction, and operational efficiency. Customer service fields complaints about delivery delays and pricing discrepancies. Finance struggles to reconcile quoted prices with actual costs, impacting profit margins and financial reporting accuracy. Operations scrambles to fulfill orders that shouldn’t have been promised in the first place, disrupting production schedules and resource allocation.

What are the main benefits of CPQ-ERP integration for manufacturing companies? The business drivers for integration have intensified dramatically as market complexity explodes and customer expectations evolve. B2B buyers now expect Amazon-like buying experiences with instant pricing, real-time availability checks, accurate delivery commitments, and self-service configuration options. Meanwhile, product portfolios have grown increasingly sophisticated, with modular designs, customizable options, subscription models, and service bundles that span multiple fulfillment channels and require complex pricing calculations.

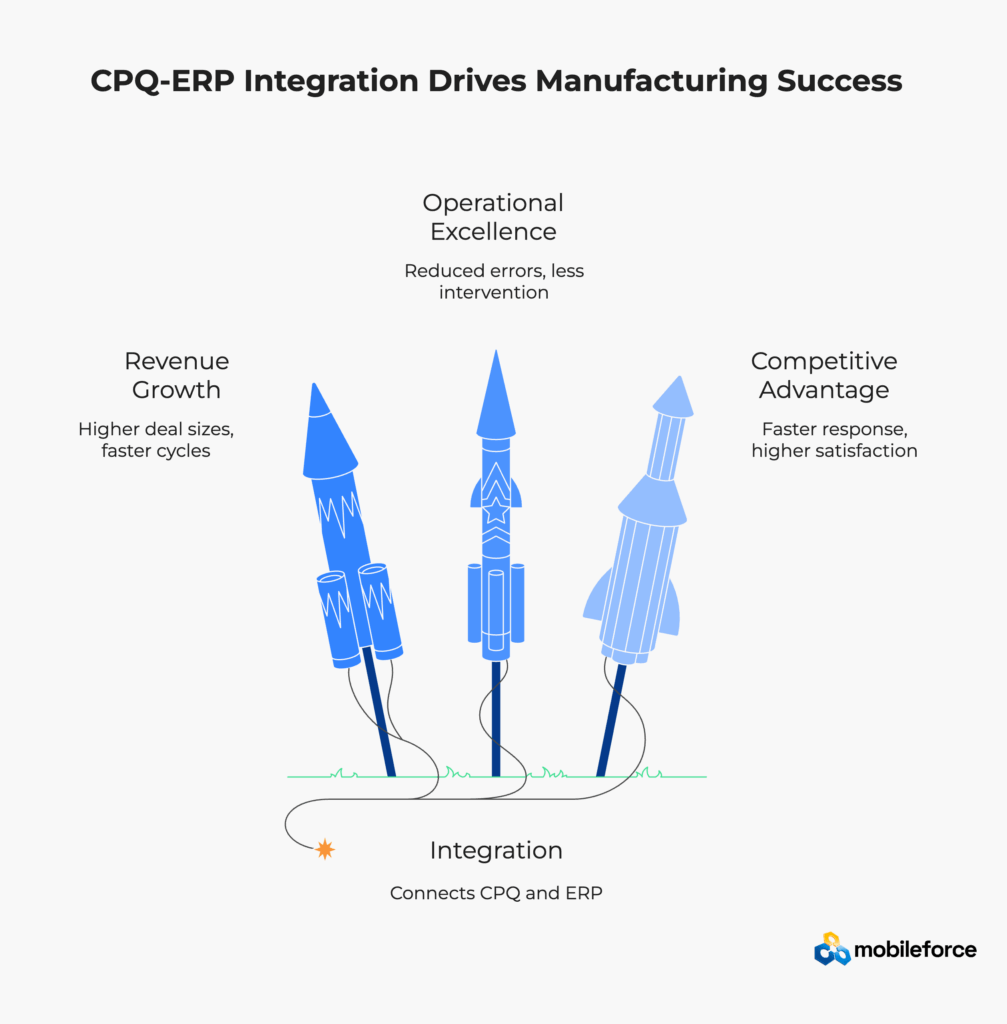

Research from Aberdeen Group’s sales profitability analysis reveals that best-in-class companies (top 20% of performers) are 3.2 times more likely to have fully integrated quote-to-cash processes. These organizations achieve remarkable results across revenue growth, operational efficiency, and competitive positioning:

The cost of inaction compounds quickly for companies delaying integration initiatives. Forrester’s quote-to-cash platform integration research estimates that pricing inconsistencies and quote errors cost the average enterprise $15-25 million annually in direct revenue leakage, not including the hidden costs of customer relationships damaged by delivery disappointments, pricing disputes, and competitive disadvantages from slow quote response times.

Ready to eliminate quote-to-cash friction and accelerate your revenue cycle? Schedule a demo with MobileForce.ai to see how integrated CPQ-ERP systems transform sales operations and drive measurable business results.

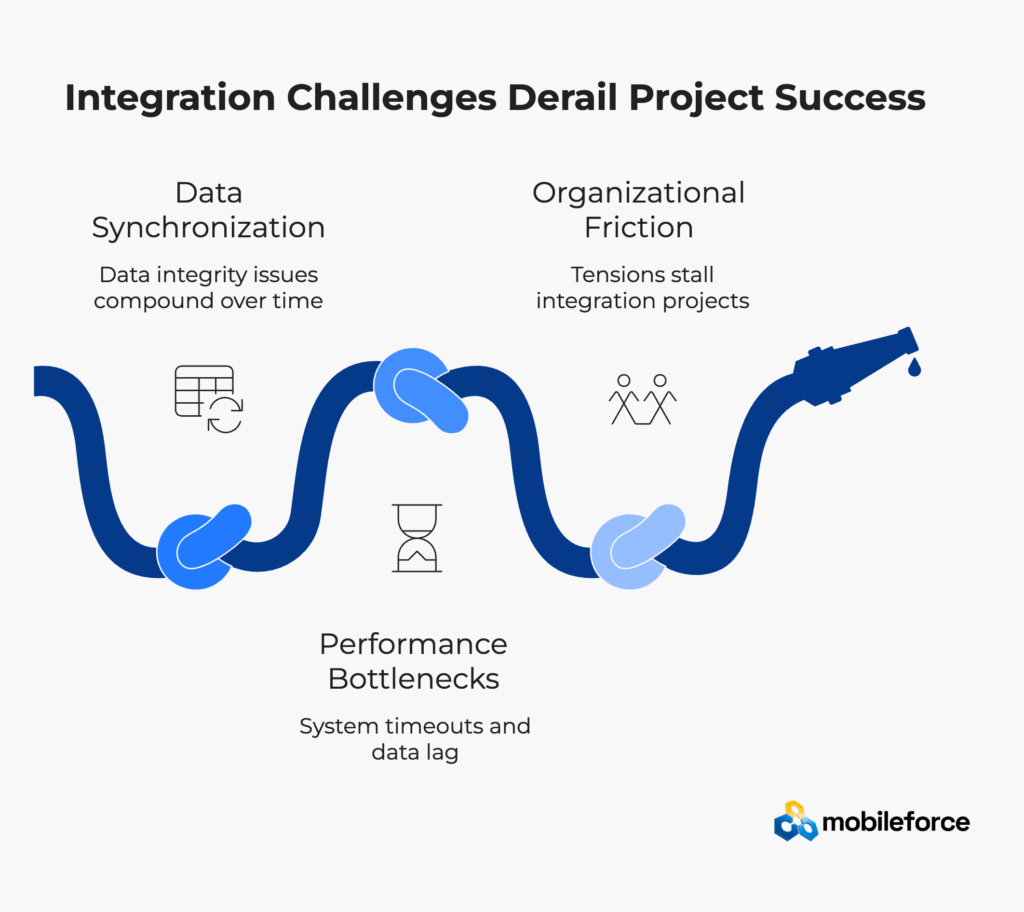

Even well-intentioned CPQ-ERP integration projects face predictable obstacles that can derail implementation timelines and business outcomes. Understanding these challenges upfront helps organizations navigate around the most expensive mistakes while building more robust integration strategies.

Data synchronization represents the most complex technical challenge in CPQ-ERP integration projects. Real-time data synchronization sounds straightforward in theory but proves devilishly complex in practice due to different data models, update frequencies, and business logic requirements. Product hierarchies rarely map cleanly between systems, creating data integrity issues. CPQ might organize products by sales categories and customer segments while ERP structures them by manufacturing processes and cost centers. When multiplied across thousands of SKUs with frequent updates, pricing changes, and promotional campaigns, these misalignments create data integrity issues that compound over time and impact quote accuracy.

A Fortune 500 technology company discovered this firsthand when their integration pushed ERP inventory data to CPQ every hour. However, their complex product configurations required real-time availability checks for multiple components simultaneously. The hourly sync created a 30-minute window where sales teams unknowingly quoted unavailable configurations, resulting in $3.2 million in order modifications during their peak quarter.

According to Gartner’s 2025 Magic Quadrant for Configure, Price and Quote Applications, 70% of integration projects face performance bottlenecks during peak usage periods, making scalability planning essential from the outset.

Integration architectures that work fine during testing often buckle under real-world volumes and concurrent user loads. Peak quoting periods—end-of-quarter pushes, seasonal campaigns, major product launches, and promotional events—stress integration points in unpredictable ways that can cause system timeouts, data lag, and user frustration.

The challenge intensifies with complex product configurations requiring multiple data lookups and calculations. A single quote might trigger dozens of ERP lookups for component availability, cost calculations, lead time estimates, and margin analysis. When sales teams generate hundreds of quotes simultaneously during busy periods, these lookup requests can overwhelm ERP systems not designed for high-frequency external queries, causing response time degradation and system instability.

Technical challenges often pale compared to organizational friction and change management issues. Sales teams resist changes that slow their quoting process, even temporarily, especially when compensation depends on meeting monthly targets. IT departments worry about system stability, security vulnerabilities, and support complexity. Finance teams want pricing controls and approval workflows that sales finds restrictive and time-consuming.

These tensions surface during implementation when cross-functional teams must agree on data ownership models, approval workflows, exception handling procedures, and performance metrics. Without clear governance frameworks and stakeholder alignment, integration projects stall in endless debates about business rules, system responsibilities, and process changes that impact daily operations.

Common Challenge | Traditional Approach | Integrated Solution | Business Impact |

Stale Product Data | Manual quarterly updates | Real-time synchronization | 67% reduction in quote errors |

Pricing Inconsistencies | Separate price lists | Unified cost-plus pricing | $2-5M annual savings |

Configuration Conflicts | Post-quote validation | Pre-quote validation | 78% fewer order modifications |

Inventory Blind Spots | Best-guess availability | Real-time inventory checks | 40% improvement in delivery accuracy |

Manual Order Entry | Sales ops transcription | Automated order generation | 15 hours weekly time savings |

Forecast Inaccuracy | Disconnected systems | Unified pipeline data | 25% improvement in forecast accuracy |

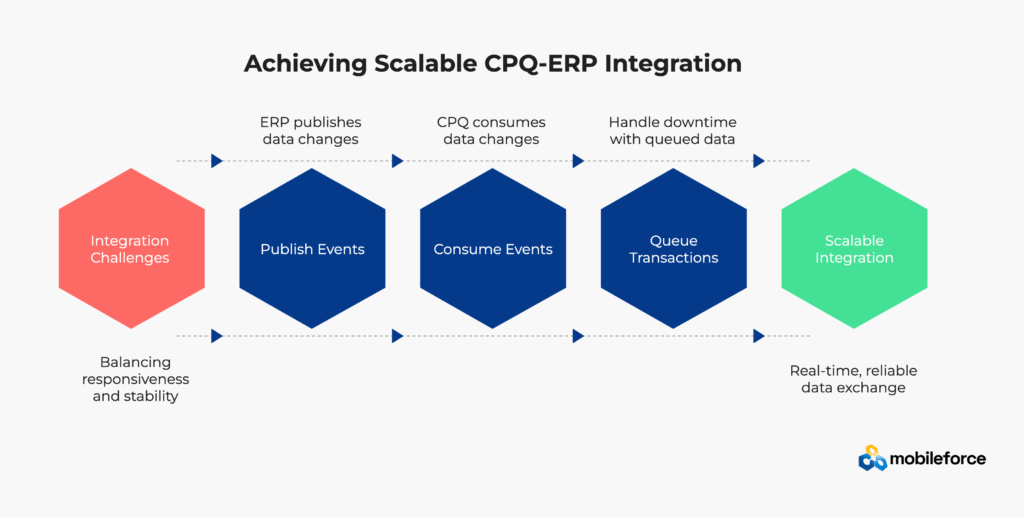

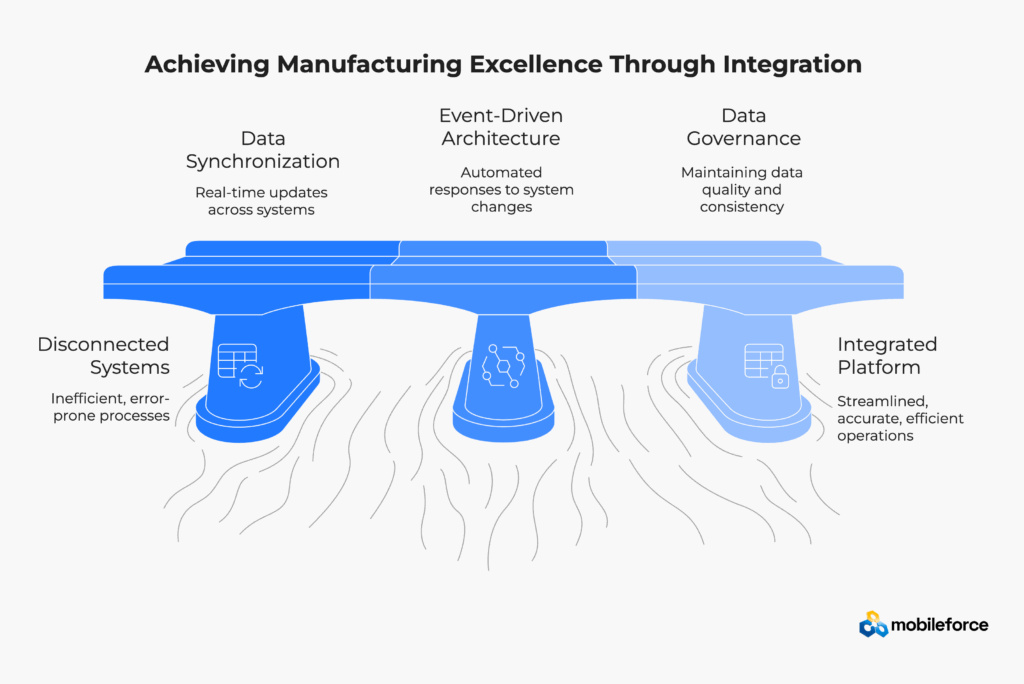

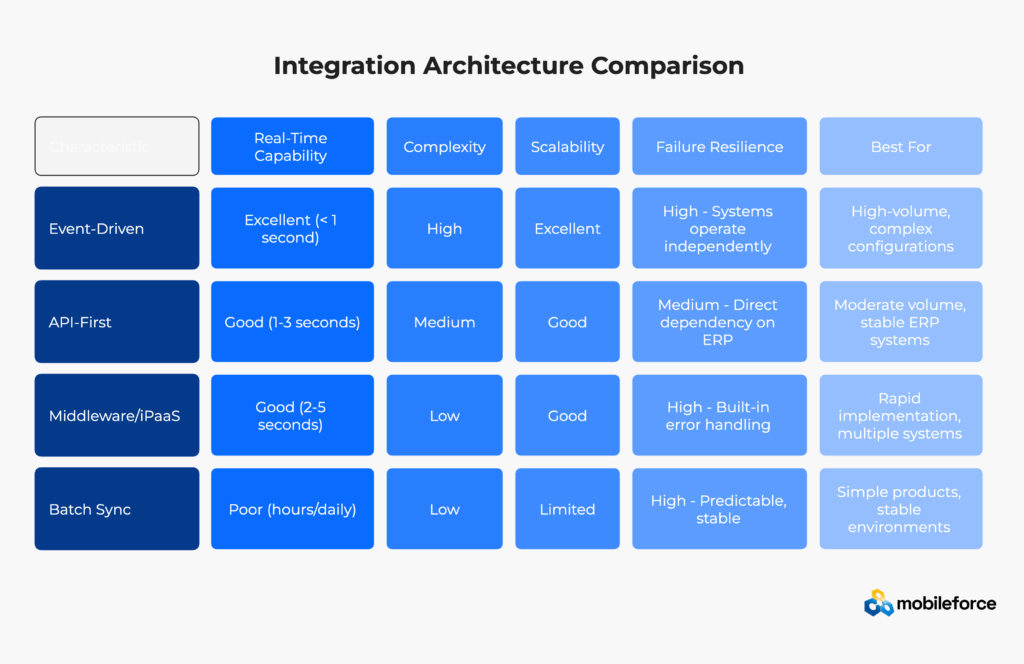

Successful CPQ-ERP integration requires thoughtful architecture choices that balance real-time responsiveness with system stability and future scalability. Three primary integration patterns have emerged, each with distinct advantages, trade-offs, and ideal use cases for different business scenarios.

Event-driven integration represents the gold standard for enterprise-scale deployments, using message queues and streaming platforms to propagate changes between systems in near real-time. When ERP updates product costs, inventory levels, or availability status, it publishes events that CPQ systems consume and process immediately. Similarly, when CPQ generates approved quotes, it publishes order events that ERP systems use to initiate fulfillment workflows and update inventory allocations.

This pattern excels at handling high volumes while maintaining loose coupling between systems and ensuring business continuity. If ERP experiences downtime or maintenance windows, CPQ continues operating with cached data and queued transactions. When ERP recovers, it processes queued events to restore synchronization without data loss or manual intervention.

A leading industrial equipment manufacturer implemented event-driven integration using Apache Kafka to handle 50,000+ product updates daily across 12 regional ERP instances feeding a global CPQ system. The architecture processes 2,000+ concurrent quote requests during peak periods while maintaining sub-second response times and 99.9% uptime availability.

McKinsey & Company’s pricing transformation research indicates that event-driven architectures deliver 40% better scalability compared to traditional synchronous integration patterns, particularly for organizations with complex product catalogs and high transaction volumes requiring real-time pricing updates.

API-based integration creates direct connections between CPQ and ERP systems using REST or SOAP interfaces, enabling real-time data access and immediate transaction processing. This approach offers simplicity in implementation and real-time data access but creates tight coupling that can propagate system failures and performance issues across integrated applications.

The pattern works well for organizations with stable, high-performance ERP systems and moderate transaction volumes that don’t require extreme scalability. However, it requires careful rate limiting, circuit breaker patterns, and error handling to prevent CPQ queries from overwhelming ERP systems during peak usage periods or system maintenance windows.

Integration Platform as a Service (iPaaS) solutions provide pre-built connectors, data transformation capabilities, monitoring tools, and drag-and-drop configuration interfaces that accelerate implementation timelines. Platforms like MuleSoft, Boomi, Dell Boomi, and Zapier handle the complexity of mapping data structures, managing retry logic, providing visibility into integration health, and supporting multiple data formats and protocols.

This approach reduces technical risk and implementation timelines but introduces additional vendor dependencies and ongoing subscription costs. For many organizations, the trade-off proves worthwhile, especially when integration requirements extend beyond CPQ and ERP to include CRM systems, marketing automation platforms, e-commerce solutions, and other business applications that require unified data management.

Sync Method | Frequency | Data Freshness | System Load | Error Recovery | Ideal Use Cases |

Real-Time Events | Immediate | Excellent | Low | Automatic | High-velocity sales, commodity pricing |

Micro-Batch (5-15 min) | Minutes | Very Good | Medium | Good | Standard manufacturing, B2B services |

Scheduled Batch (Hourly) | 1-4 hours | Good | Low | Manual | Stable products, predictable demand |

Daily Batch | 24 hours | Poor | Very Low | Manual | Simple products, low volume |

Looking to accelerate your CPQ-ERP integration timeline while minimizing technical risk? Explore MobileForce.ai’s proven integration capabilities and see how our platform handles complex product configurations, high-volume scenarios, and real-time data synchronization requirements.

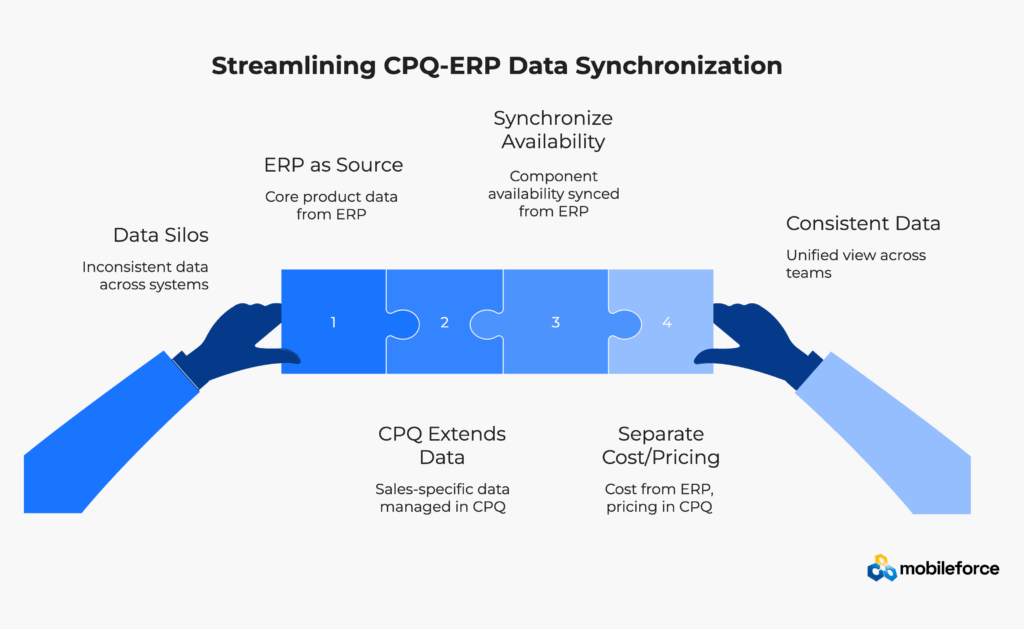

The foundation of successful CPQ-ERP integration rests on well-designed data models that accommodate both systems’ requirements while minimizing ongoing maintenance overhead and ensuring data consistency across sales and operations teams.

Product master data represents the most critical and complex aspect of CPQ-ERP integration projects. ERP systems typically maintain comprehensive product records including manufacturing details, cost structures, supplier relationships, quality specifications, and lifecycle status information. CPQ systems need selling-focused product information: customer-facing descriptions, configuration options, pricing rules, discount matrices, and compatibility constraints that enable guided selling and accurate quoting.

The challenge lies in maintaining consistency across these different product perspectives without duplicating maintenance effort or creating data silos. Leading organizations establish ERP as the authoritative source for core product attributes—SKU identifiers, cost data, manufacturing status, and inventory levels—while allowing CPQ to extend these records with sales-specific information like competitive positioning, sales messaging, and customer success stories.

A modular approach works well for complex configurable products and custom manufacturing scenarios. ERP maintains individual component records with their manufacturing and cost details, supplier information, and quality specifications. CPQ maintains configuration rules that define valid combinations, calculate composite pricing, and guide sales representatives through complex product selection processes. Integration synchronizes component availability and costs while preserving CPQ’s flexibility to manage configuration logic and customer-facing presentation.

Manufacturing companies with complex product structures face unique integration challenges when dealing with bill of materials synchronization. Multi-level BOMs with optional components, alternative materials, configuration-dependent assembly processes, and supplier-specific variations require sophisticated mapping between ERP manufacturing views and CPQ selling views that customers can understand and navigate.

Consider an enterprise software company selling configurable hardware appliances with complex dependencies. Their ERP system tracks 15,000+ individual components across multiple BOM levels, including field-replaceable units, software licenses, service packages, and maintenance contracts. The CPQ system presents these as 200 customer-facing configuration options with dependency rules, pricing algorithms, and guided selling workflows that simplify complex decisions.The integration synchronizes component availability and costs from ERP while allowing CPQ to maintain its own abstraction layer for customer interactions and sales processes. When ERP discontinues a specific memory module or updates supplier information, the integration updates CPQ to remove that option from new configurations while preserving existing quotes that reference it, ensuring quote integrity and customer commitments.

Pricing represents another integration complexity, particularly for organizations with sophisticated pricing strategies, customer-specific agreements, and dynamic market conditions. ERP systems calculate standard costs based on materials, labor, overhead allocation, and supplier contracts. CPQ systems apply customer-specific discounts, volume tiers, promotional pricing, margin rules, and competitive adjustments that reflect market positioning and sales strategy.

Effective integration strategies separate cost data (synchronized from ERP) from pricing logic (maintained in CPQ) to enable financial control while preserving sales flexibility. This separation allows finance teams to update cost structures in ERP based on supplier changes and manufacturing efficiency while preserving sales teams’ flexibility to manage customer-specific pricing strategies, promotional campaigns, and competitive responses.

Real-time cost updates prove essential for maintaining margin integrity and competitive positioning during volatile market conditions. A global technology distributor implemented event-driven cost synchronization that updates CPQ pricing within seconds of ERP cost changes. This capability proved crucial during supply chain disruptions when component costs fluctuated daily, allowing sales teams to adjust quotes immediately rather than discovering margin erosion weeks later during financial reconciliation processes.

Deloitte’s 2024 Supply Chain Survey findings found that companies with real-time cost visibility maintained 23% better gross margins during periods of supply chain volatility compared to those relying on batch updates and manual pricing adjustments.

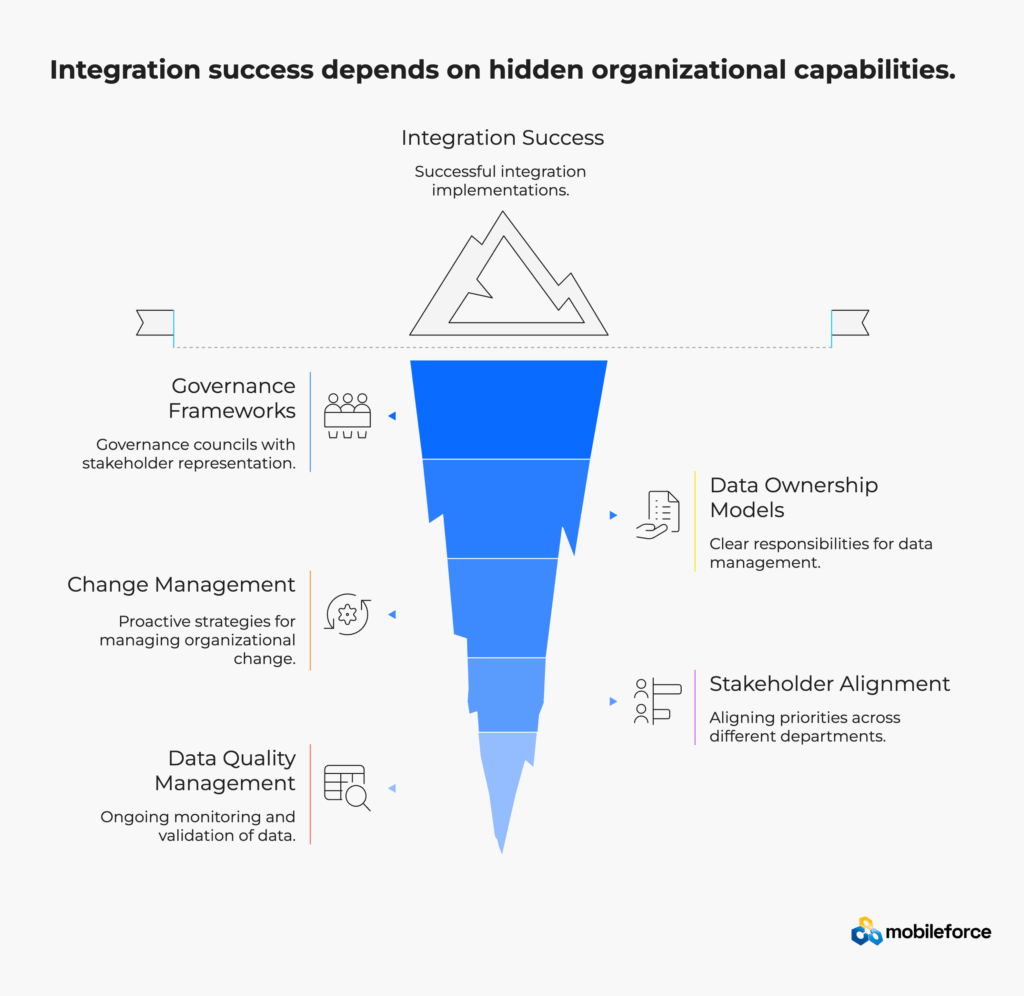

Technology choices matter, but organizational capabilities often determine integration success more than architectural decisions or software selection. Effective governance frameworks, clear data ownership models, proactive change management, and stakeholder alignment separate successful implementations from expensive failed attempts that drain resources without delivering business value.

CPQ-ERP integration impacts multiple departments with potentially conflicting priorities and success metrics. Sales wants speed, flexibility, and customer responsiveness. Operations demands accuracy, predictability, and process control. Finance requires cost controls, margin protection, and auditability. IT prioritizes stability, security, and maintainability while managing multiple system dependencies and vendor relationships.

Successful organizations establish governance councils with representation from each stakeholder group and clear escalation procedures for resolving conflicts that arise during implementation and ongoing operations. These councils define data ownership responsibilities, approve integration scope changes, establish performance metrics that balance competing priorities, and monitor key performance indicators that align with overall business objectives.

A manufacturing conglomerate with $8 billion in annual revenue credits their integration success to a governance model that includes monthly business reviews, quarterly technical assessments, and annual strategic planning sessions. The council tracks metrics like quote accuracy rates, order modification frequencies, system performance indicators, user adoption rates, and customer satisfaction scores, adjusting integration priorities based on business impact rather than technical convenience or vendor recommendations.

Research from Boston Consulting Group’s digital transformation research shows that organizations with structured governance frameworks achieve 65% higher success rates in large-scale integration projects compared to those without formal oversight structures and clear accountability models.

Integration amplifies data quality issues exponentially, turning minor inconsistencies into major operational problems. Inconsistent product descriptions in ERP become customer-facing confusion in CPQ quotes and proposals. Incomplete cost data creates pricing gaps and margin leakage. Outdated lifecycle status allows quotes for discontinued products, resulting in unfulfillable orders and customer disappointment.

Leading organizations invest heavily in data cleanup before integration and establish ongoing data quality monitoring afterward with automated validation rules, exception reporting, and regular data audits. Automated validation rules flag anomalies like missing cost data, orphaned product records, configuration rules that reference non-existent components, and pricing inconsistencies that could impact quote accuracy or customer satisfaction.

The investment pays dividends quickly through improved operational efficiency and customer experience. A global industrial supplier discovered that 12% of their product records had incomplete or inconsistent data during their pre-integration assessment. After cleanup, they achieved 95% first-quote accuracy rates compared to 60% before integration, eliminating thousands of quote revisions annually and improving sales productivity significantly.

According to IBM’s Data Quality Research, poor data quality costs organizations an average of $3.1 trillion annually in the United States alone, with manufacturing and distribution companies bearing disproportionate impacts due to complex product hierarchies, multi-tier pricing structures, and diverse customer requirements.

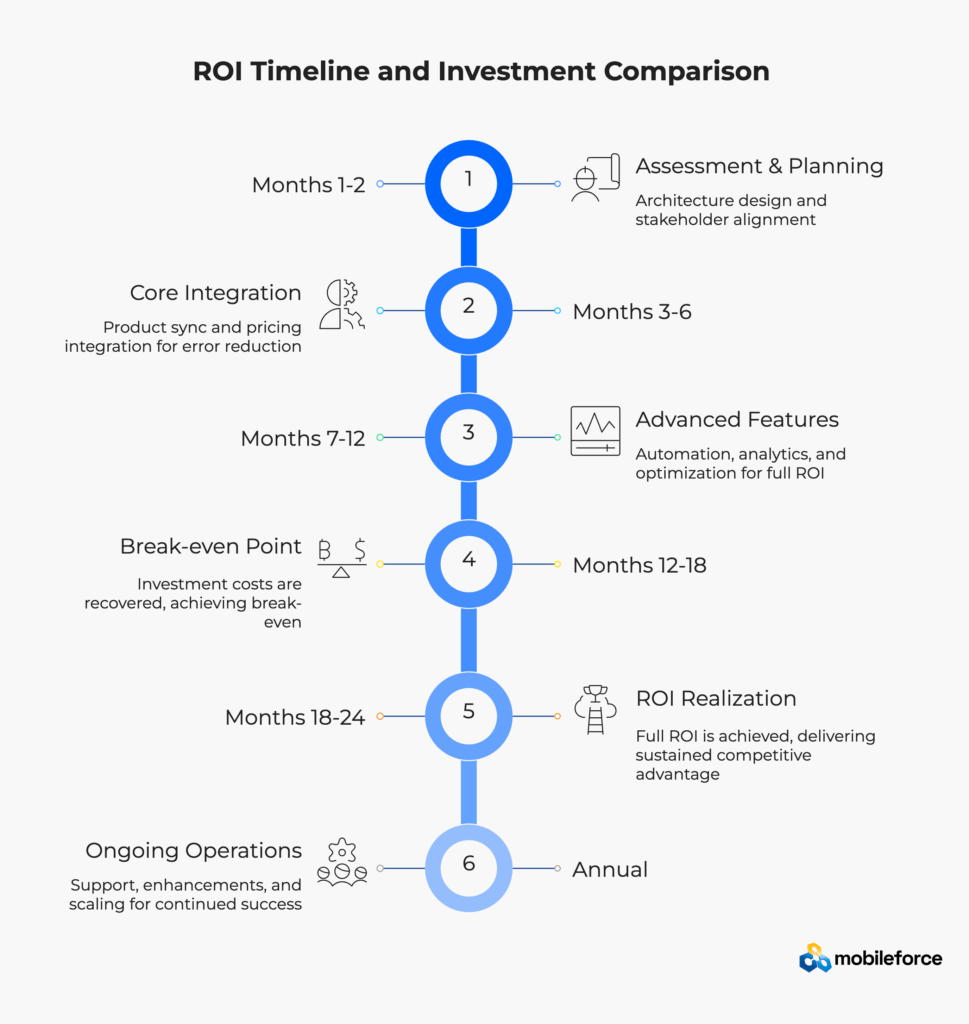

Investment Phase | Timeline | Cost Range | Key Deliverables | ROI Milestone |

Assessment & Planning | Months 1-2 | $50K-150K | Architecture design, stakeholder alignment | Foundation for success |

Core Integration | Months 3-6 | $200K-800K | Product sync, pricing integration | 40% error reduction |

Advanced Features | Months 7-12 | $150K-500K | Automation, analytics, optimization | Full ROI realization |

Ongoing Operations | Annual | $100K-300K | Support, enhancements, scaling | Sustained competitive advantage |

Typical ROI Realization: 18-24 months | Break-even Point: 12-18 months | 5-Year NPV: 300-500% of investment

Even perfect technical integration fails without user adoption and organizational buy-in. Sales teams accustomed to manual workarounds and familiar processes resist new systems that initially slow their workflow or require additional training. Operations staff struggle with new order formats, approval procedures, and exception handling processes that differ from established routines.

Comprehensive training programs address both technical skills and business process changes while demonstrating clear value to end users. Role-specific training modules focus on relevant integration capabilities rather than overwhelming users with system-wide functionality they won’t use. Ongoing reinforcement sessions, peer mentoring programs, and regular feedback collection help teams optimize their usage patterns as they gain experience and confidence with new processes.

Change management extends beyond initial training to include performance incentives aligned with integration success and business outcomes. Sales compensation plans that reward quote accuracy alongside revenue generation encourage adoption of new validation procedures and data quality practices. Operations teams receive recognition for reducing order modification frequencies, improving fulfillment predictability, and contributing to customer satisfaction improvements.

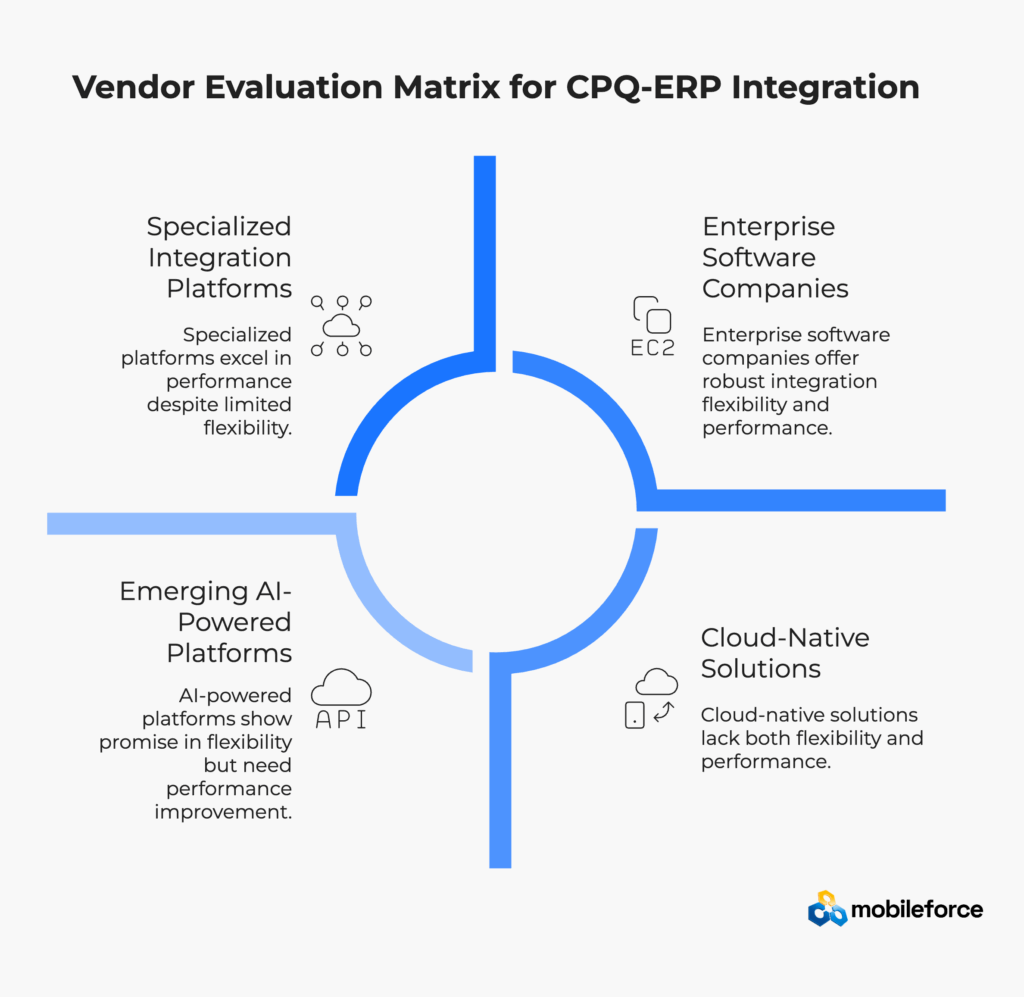

The CPQ-ERP integration vendor landscape includes established enterprise software companies, specialized integration platforms, cloud-native solutions, and emerging AI-powered platforms. Each category offers distinct advantages depending on organizational requirements, technical constraints, budget considerations, and implementation timelines.

Transform your quote-to-cash process with proven integration expertise. Connect with MobileForce.ai to evaluate how our platform addresses your specific CPQ-ERP integration challenges, scalability requirements, and business objectives.

Comprehensive vendor evaluation requires assessment across multiple dimensions beyond basic functional capabilities and pricing models. Integration flexibility, performance characteristics, ongoing support quality, implementation methodology, and long-term vendor viability often matter more than feature checklists or initial licensing costs.

Real-Time vs. Batch Synchronization Capabilities: Organizations with high-velocity sales processes, dynamic pricing strategies, and time-sensitive promotions require near real-time data synchronization capabilities. Others benefit from the stability and predictability of scheduled batch updates that reduce system complexity and infrastructure costs. Leading vendors offer both options with configuration flexibility and hybrid approaches that combine real-time critical updates with batch synchronization for less time-sensitive data.

Complex Product Configuration Support: Vendors vary significantly in their ability to handle nested product configurations, multi-level BOMs, dependency rules, and constraint-based selling scenarios. Organizations with sophisticated product catalogs, configurable manufacturing, or complex service offerings should prioritize vendors with proven experience in their specific industry vertical and similar use cases.

API Quality and Documentation: Integration success depends heavily on API reliability, performance characteristics, comprehensive documentation, and developer support resources. Vendors with well-documented APIs, SDK availability, sandbox environments, and active developer communities reduce implementation risk, accelerate development timelines, and simplify ongoing maintenance requirements.

Monitoring and Observability Tools: Integration health monitoring, error tracking, performance analytics, and business intelligence capabilities distinguish enterprise-grade solutions from basic connectivity tools. These capabilities prove essential for maintaining integration reliability at scale, troubleshooting issues quickly, and optimizing performance over time.

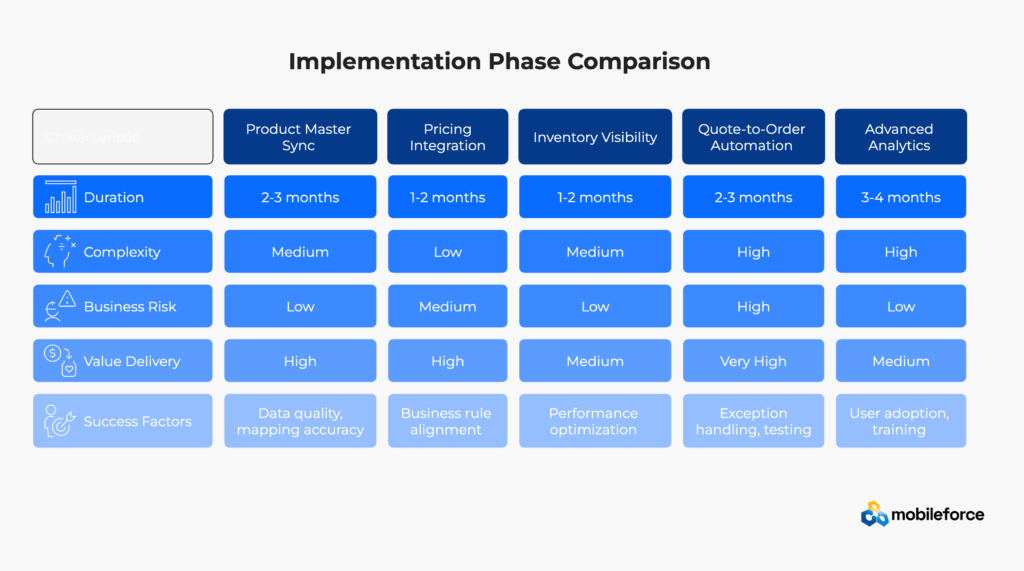

Phase | Duration | Complexity | Business Risk | Value Delivery | Success Factors |

Product Master Sync | 2-3 months | Medium | Low | High | Data quality, mapping accuracy |

Pricing Integration | 1-2 months | Low | Medium | High | Business rule alignment |

Inventory Visibility | 1-2 months | Medium | Low | Medium | Performance optimization |

Quote-to-Order Automation | 2-3 months | High | High | Very High | Exception handling, testing |

Advanced Analytics | 3-4 months | High | Low | Medium | User adoption, training |

Integration costs extend far beyond initial licensing and implementation fees, requiring comprehensive analysis across a 5-year horizon. Organizations should evaluate total cost of ownership including implementation services, ongoing maintenance, performance optimization, user training, system upgrades, and scalability investments that support business growth.

Implementation and Configuration Costs: Complex integrations require significant professional services investment for data mapping, business rule configuration, testing procedures, and user training programs. Vendors with pre-built industry templates, configuration accelerators, and proven implementation methodologies reduce these costs substantially while minimizing project risk and timeline delays.

Ongoing Maintenance and Support: Integration maintenance includes software updates, data model changes, performance tuning, troubleshooting support, and vendor relationship management. Cloud-native solutions typically offer lower maintenance overhead compared to on-premises installations but may involve higher subscription costs and data transfer fees.

Performance and Scalability Costs: High-volume integration scenarios may require additional infrastructure, premium support tiers, performance optimization services, or architectural upgrades as transaction volumes grow. Understanding these scaling costs upfront prevents budget surprises and enables better long-term financial planning for growth scenarios.

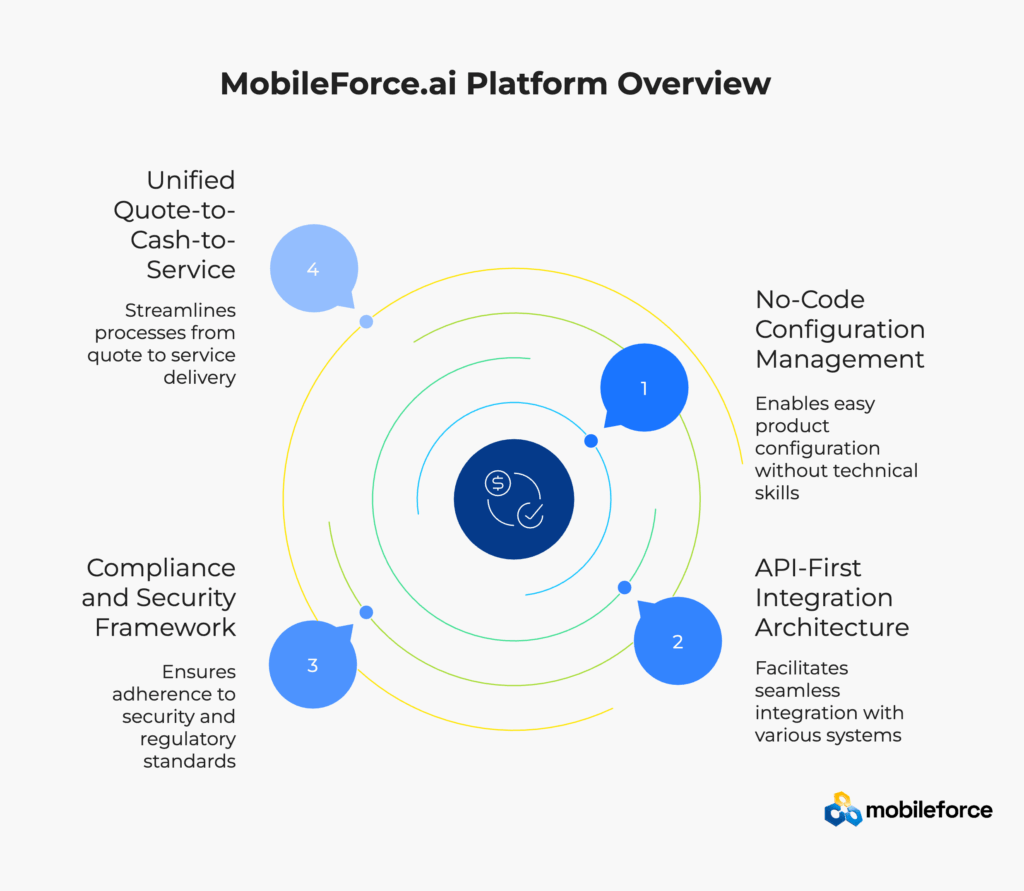

MobileForce.ai has developed a comprehensive CPQ-ERP integration platform specifically designed to address the challenges that derail traditional integration projects. The platform combines real-time synchronization capabilities with sophisticated error handling and business rule management.

MobileForce.ai’s no-code platform enables sales operations teams to manage complex product configurations without technical expertise. The platform supports multi-tiered pricing, configurable product catalogs, and sophisticated business rules that integrate bi-directionally with leading ERP systems.

The platform’s AskCPQ™ feature allows sales teams to generate quotes using natural language prompts, automatically validating product combinations against real-time inventory and pricing data from integrated ERP systems. This AI-powered approach eliminates configuration errors while accelerating quote generation.

MobileForce.ai’s API-first design enables seamless integration with CRM systems (Salesforce, HubSpot, Microsoft Dynamics) and back-office applications including ERP, inventory management, and payment systems. The platform’s bidirectional integration ensures data consistency across all connected systems.

Customer implementations demonstrate significant performance improvements, with SportSafe reporting an 80% reduction in quote generation time after integration with their existing systems. The platform’s mobile-first design includes offline capabilities, ensuring field teams can generate quotes and access CRM data regardless of connectivity.

The platform meets enterprise security requirements with SOC 2, GDPR, and ISO 22301:2019 compliance certifications. Built-in audit trails track all integration activities and user actions, supporting regulatory requirements and internal governance policies.

MobileForce.ai’s unified quote-to-cash-to-service platform extends beyond traditional CPQ functionality to include field service management, creating seamless workflows from initial quote through service delivery and ongoing customer support.

A mid-sized manufacturing company specializing in industrial automation equipment faced mounting pressure from integration challenges. Their sales team used Salesforce CPQ to handle complex product configurations, while their operations team relied on SAP ERP for inventory management and order fulfillment.

The disconnect between systems created multiple pain points. Sales representatives frequently quoted discontinued products because CPQ product data was updated manually on a quarterly basis. Pricing was based on standard costs that hadn’t been updated in six months, resulting in margin erosion on 30% of orders.

Order handoffs required manual intervention in 60% of cases, with sales operations staff spending 15 hours weekly resolving configuration mismatches between CPQ quotes and ERP orders. Customer satisfaction suffered as delivery promises made during sales processes proved unattainable due to inventory shortages or manufacturing constraints not visible in CPQ.

The company implemented a phased integration approach starting with product master data synchronization. Real-time inventory levels and cost updates followed, with full quote-to-order automation completing the integration after six months of careful testing and refinement.

Event-driven architecture enabled near real-time synchronization while maintaining system independence. When SAP updated product costs or inventory levels, integration events triggered immediate CPQ updates. Approved quotes generated order events that SAP processed automatically without manual intervention.

Customer implementations demonstrate measurable improvements across multiple dimensions:

Operational Excellence: Quote accuracy rates improved significantly, with customers reporting up to 90% fewer errors in order flows. The platform’s real-time validation capabilities eliminate configuration mismatches before quotes reach fulfillment teams.

Sales Productivity: SportSafe achieved an 80% reduction in quote generation time after implementing MobileForce.ai’s integrated platform. Sales representatives gained substantial time for customer-facing activities through automated data validation and quote generation processes.

Revenue Acceleration: Customers report up to 55% reduction in quote-to-close-to-revenue cycles through streamlined approval workflows and automated order processing. The platform’s unified approach eliminates handoff delays between sales, operations, and service teams.

System Integration: MobileForce.ai’s bidirectional integration with CRM and ERP systems provides real-time inventory visibility and pricing accuracy. The platform’s API-first architecture supports complex business scenarios while maintaining data consistency across all connected systems.

Several factors contributed to the integration’s success beyond technology choices. Executive sponsorship ensured cross-functional cooperation during challenging implementation phases. Comprehensive user training addressed both technical skills and business process changes.

Most importantly, the organization established clear data governance procedures that prevented the data quality degradation that often undermines integration benefits over time.

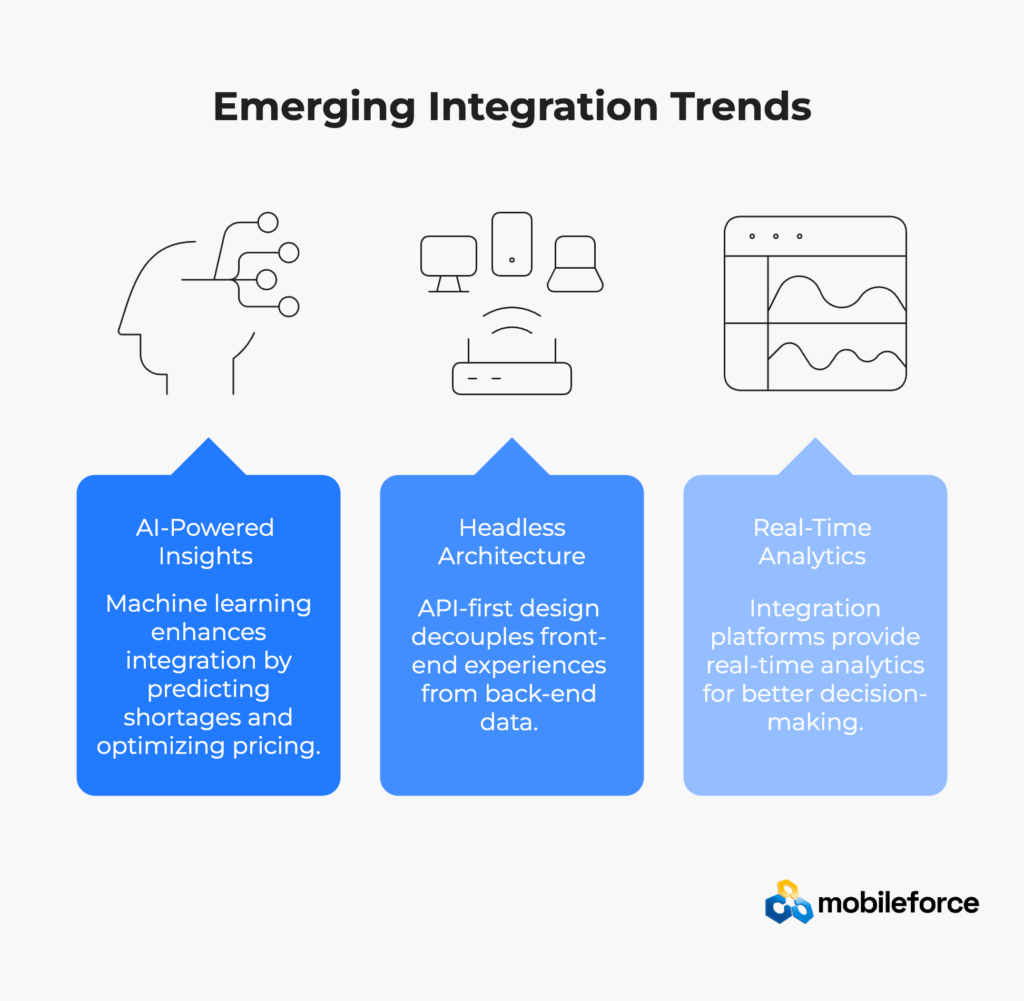

The CPQ-ERP integration landscape continues evolving rapidly, driven by advances in artificial intelligence, cloud computing, and real-time analytics. Organizations planning integration initiatives should consider these emerging capabilities to maximize long-term value.

Machine learning algorithms increasingly enhance CPQ-ERP integration by predicting inventory shortages, optimizing pricing strategies, and identifying configuration patterns that cause fulfillment delays. These predictive capabilities enable proactive rather than reactive integration management.

Advanced analytics can identify seasonal demand patterns that inform inventory positioning and pricing strategies. When integrated CPQ-ERP systems detect quote velocity increases for specific product categories, they can trigger automatic reorder points and adjust pricing to optimize margin and availability balance.

MIT Technology Review’s AI business applications research reports that organizations leveraging AI in their quote-to-cash processes achieve 28% better inventory turnover rates and 19% improvement in pricing optimization compared to traditional rule-based systems.

Modern integration architectures emphasize API-first design principles that decouple front-end user experiences from back-end data management. This approach enables organizations to customize sales tools and customer portals without disrupting core integration logic.

Headless CPQ platforms allow organizations to embed quoting capabilities directly into customer portals, e-commerce platforms, or mobile applications while maintaining unified data management with ERP systems. This flexibility proves increasingly important as B2B buying processes become more self-service oriented.

Accenture’s Digital Commerce Report found that 84% of B2B buyers prefer self-service options for routine purchases, driving demand for embedded quoting capabilities that maintain integration with back-office systems.

Integration platforms increasingly provide real-time analytics that help sales teams make better decisions during the quoting process. Margin analysis, competitive positioning insights, and deal probability scoring enhance sales effectiveness while maintaining integration with operational systems.

These capabilities transform CPQ from a quote generation tool into a comprehensive sales intelligence platform that leverages the full breadth of ERP data to guide customer interactions.

Ready to future-proof your quote-to-cash process with next-generation integration capabilities? Schedule a consultation with MobileForce.ai to explore how AI-powered integration can transform your sales operations.

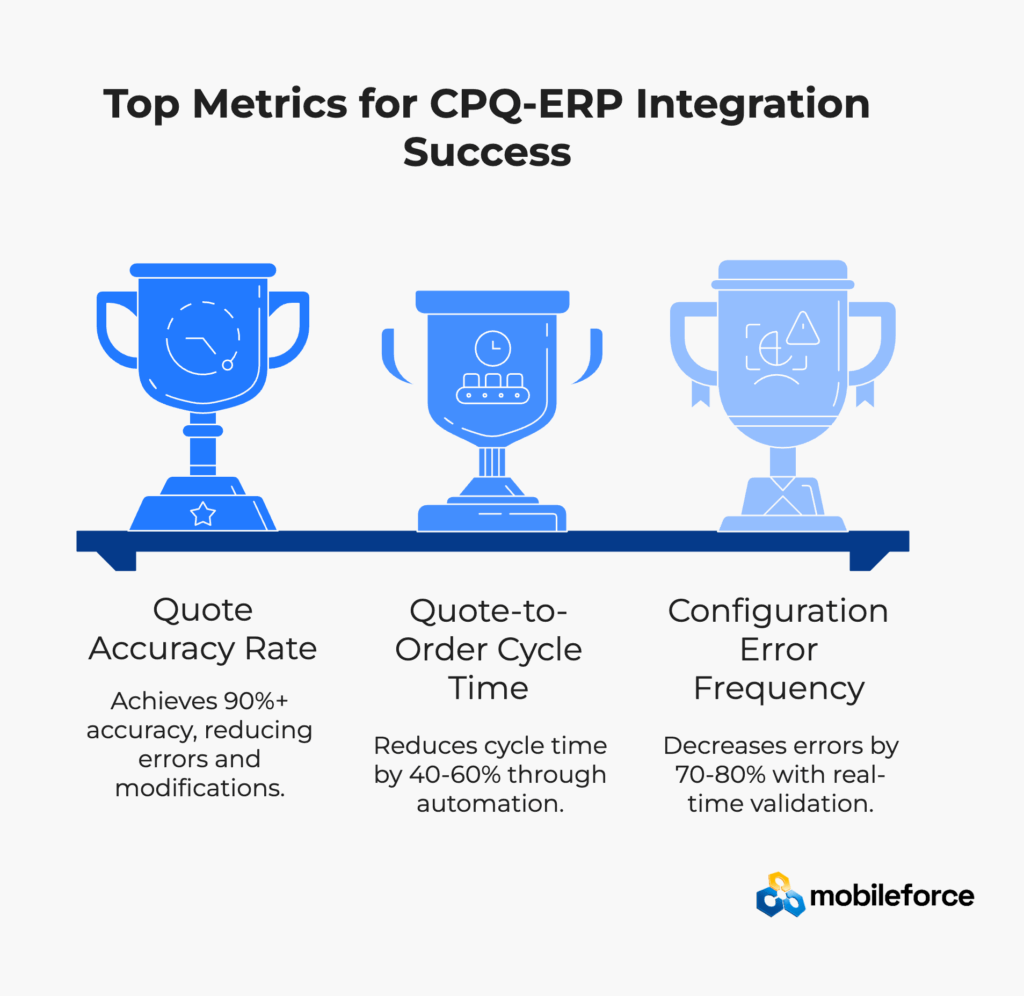

Successful CPQ-ERP integration requires comprehensive measurement frameworks that track both operational improvements and business outcomes. Leading organizations monitor multiple categories of metrics to ensure integration delivers sustained value.

Quote Accuracy Rate: The percentage of quotes that require no modifications after customer acceptance. Best-in-class organizations achieve 90%+ accuracy rates, compared to 60-70% for companies with disconnected systems.

Quote-to-Order Cycle Time: Average time from initial quote generation to order entry in ERP. Integrated systems typically reduce this cycle by 40-60% through automated handoffs and validation.

Configuration Error Frequency: Number of orders requiring modification due to configuration issues. Effective integration reduces these errors by 70-80% through real-time validation.

According to PwC’s Operations Survey, companies with integrated quote-to-cash processes report 32% fewer customer complaints related to order accuracy and delivery commitments.

Revenue Leakage Reduction: Quantified savings from eliminated pricing errors, configuration mistakes, and delivery commitments that can’t be fulfilled. Organizations typically see $2-5 million annual savings per billion dollars in revenue.

Sales Productivity Gains: Time savings from automated processes, reduced quote revisions, and eliminated manual data lookups. Sales representatives often gain 10-15 hours weekly for customer-facing activities.

Customer Satisfaction Improvements: Measured through Net Promoter Scores, customer retention rates, and complaint frequencies related to pricing and delivery issues.

Forecast Accuracy: Improvement in demand forecasting enabled by connected quote and order data. Integrated systems typically improve forecast accuracy by 15-25%.

Time-to-Market for New Products: Acceleration of new product launches through streamlined product data management and configuration setup.

Competitive Win Rates: Improvement in competitive situations enabled by faster quote response times and more accurate pricing.

Harvard Business Review’s competitive dynamics research indicates that companies with integrated quote-to-cash processes win 34% more competitive deals due to superior responsiveness and pricing accuracy.

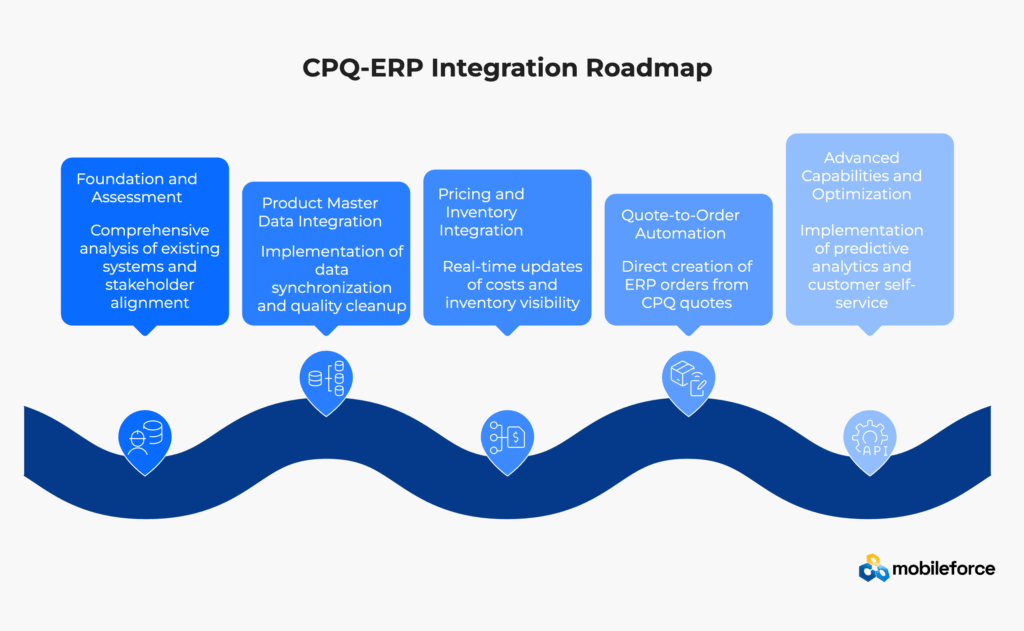

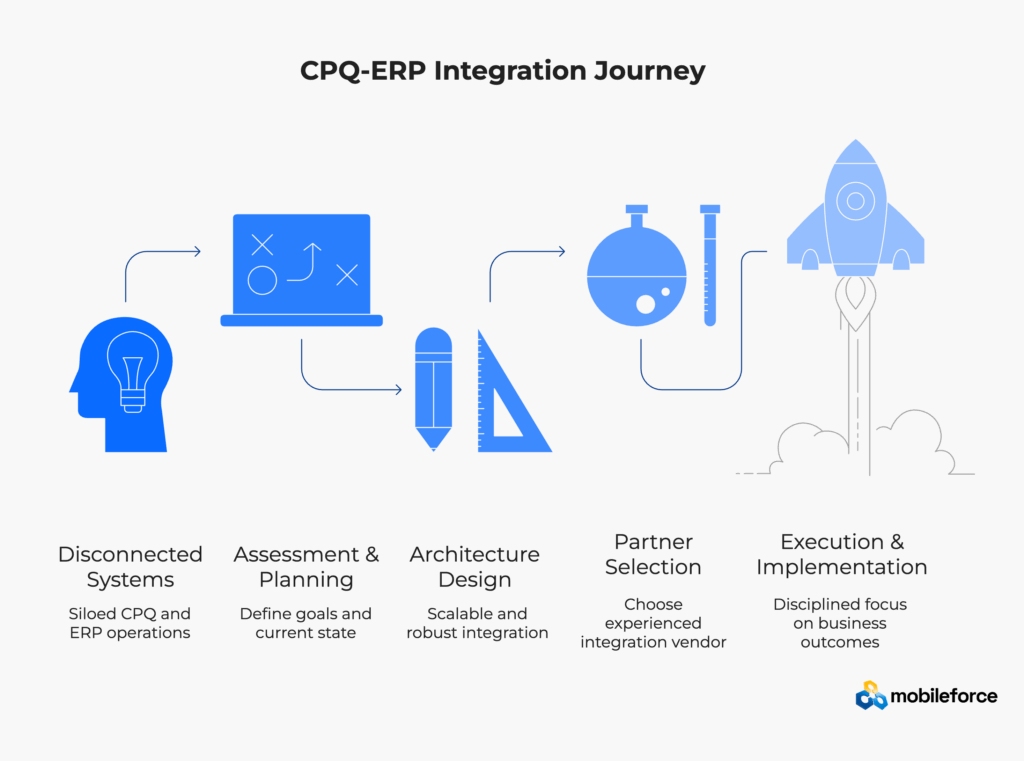

Successful CPQ-ERP integration requires careful planning and phased execution that minimizes business disruption while delivering incremental value. This proven roadmap has guided hundreds of successful implementations across various industries.

Current State Analysis: Comprehensive audit of existing CPQ and ERP systems, data quality, integration points, and business processes. This assessment identifies the biggest pain points and highest-value integration opportunities.

Stakeholder Alignment: Cross-functional workshops to define integration objectives, success criteria, and governance structures. Early stakeholder buy-in prevents scope creep and reduces organizational resistance.

Architecture Planning: Technical architecture design that addresses scalability, security, and maintainability requirements while supporting defined business objectives.

Data Synchronization Setup: Implementation of real-time or near real-time product data synchronization between ERP and CPQ systems. This foundation enables all subsequent integration capabilities.

Data Quality Cleanup: Correction of product data inconsistencies, incomplete records, and mapping conflicts identified during assessment phase.

Validation Rule Implementation: Business rules that ensure data consistency and catch integration errors before they impact customer-facing processes.

Cost Data Synchronization: Real-time updates of product costs from ERP to CPQ, enabling accurate margin calculations and pricing decisions.

Inventory Visibility: Integration of current inventory levels and lead times to support realistic delivery commitments during quoting.

Advanced Pricing Rules: Implementation of sophisticated pricing logic that considers customer segments, volume tiers, and promotional strategies.

Automated Order Generation: Direct creation of ERP orders from approved CPQ quotes, eliminating manual intervention and reducing errors.

Exception Handling: Comprehensive error handling and escalation procedures for edge cases that require human intervention.

Performance Optimization: Fine-tuning of integration performance to handle peak transaction volumes without degradation.

Predictive Analytics: Implementation of AI-powered insights that enhance quoting accuracy and identify optimization opportunities.

Customer Self-Service: Extension of integration capabilities to support customer portals and self-service quoting tools.

Continuous Improvement: Establishment of ongoing optimization processes that adapt integration capabilities to changing business requirements.

Architecture Pattern | Real-Time Capability | Complexity | Scalability | Failure Resilience | Best For |

Event-Driven | Excellent (< 1 second) | High | Excellent | High – Systems operate independently | High-volume, complex configurations |

API-First | Good (1-3 seconds) | Medium | Good | Medium – Direct dependency on ERP | Moderate volume, stable ERP systems |

Middleware/iPaaS | Good (2-5 seconds) | Low | Good | High – Built-in error handling | Rapid implementation, multiple systems |

Batch Sync | Poor (hours/daily) | Low | Limited | High – Predictable, stable | Simple products, stable environments |

Business Area | Without Integration | With Integration | Improvement Range |

Quote Accuracy | 60-70% first-time accuracy | 90-95% first-time accuracy | 25-35% improvement |

Quote-to-Order Time | 3-7 days average | 1-2 days average | 40-60% reduction |

Revenue Leakage | $15-25M annually (enterprise) | $3-8M annually | 60-80% reduction |

Sales Productivity | 40% time on admin tasks | 15% time on admin tasks | 10-15 hours weekly savings |

Order Modifications | 35-45% require changes | 8-15% require changes | 70-80% reduction |

Forecast Accuracy | 65-75% accuracy | 80-90% accuracy | 15-25% improvement |

Capability | Weight | Enterprise Vendors | Cloud-Native Solutions | Integration Platforms |

Real-Time Sync | 20% | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

Complex Configurations | 18% | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ |

Implementation Speed | 15% | ⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

Scalability | 15% | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ |

Total Cost of Ownership | 12% | ⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ |

Support Quality | 10% | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ |

API Quality | 10% | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ |

Rating Scale: ⭐ = Poor, ⭐⭐ = Fair, ⭐⭐⭐ = Good, ⭐⭐⭐⭐ = Very Good, ⭐⭐⭐⭐⭐ = Excellent

Ready to transform your quote-to-cash process with seamless CPQ-ERP integration? Contact MobileForce.ai today to schedule a personalized demonstration and discover how our proven integration platform can eliminate pricing errors, accelerate sales cycles, and drive revenue growth for your organization.

The integration of CPQ and ERP systems represents more than a technical upgrade—it’s a strategic transformation that touches every aspect of the quote-to-cash process and competitive positioning. Organizations that approach this integration thoughtfully, with proper planning, stakeholder alignment, and proven methodologies, position themselves for sustained competitive advantage in an increasingly complex B2B landscape characterized by demanding buyers, dynamic pricing pressures, and operational complexity.

The evidence is overwhelming across industries and company sizes. Companies with integrated CPQ-ERP ecosystems consistently outperform their peers across every meaningful metric: higher win rates, faster sales cycles, improved profit margins, enhanced customer satisfaction, and greater operational efficiency. The question isn’t whether to integrate these critical systems, but how quickly you can implement integration capabilities that turn operational friction into revenue acceleration and competitive differentiation.

Success requires more than selecting the right technology platform or vendor partnership. The most successful integrations combine robust technical architecture with comprehensive change management, clear governance frameworks, ongoing optimization processes, and strong executive sponsorship. Organizations that invest in these foundational elements realize sustainable competitive advantages that compound over time and create lasting business value.

Your customers expect accuracy, speed, reliability, and transparency in every interaction across all touchpoints. Integrated CPQ-ERP systems deliver exactly that while providing your teams with the insights, efficiency gains, and automation capabilities they need to excel in competitive markets. The companies that recognize this imperative today will define the competitive landscape tomorrow.

The path forward is clear: assess your current state capabilities, design your target architecture with scalability in mind, select proven integration partners with industry expertise, and execute with disciplined focus on business outcomes and user adoption. The revenue acceleration and operational excellence that await make this one of the highest-impact investments your organization can make for sustainable growth and market leadership.

Core data synchronization typically includes product master data (SKUs, descriptions, technical specifications), current inventory levels and availability status, standard costs and pricing information, bill of materials structures and component relationships, and product lifecycle status. Advanced integrations also sync customer-specific pricing agreements, lead times and delivery schedules, manufacturing capacity constraints, and promotional pricing rules. The specific data requirements depend on your product complexity, sales processes, customer requirements, and operational workflows.

Real-time synchronization isn’t always required, but it’s increasingly important for competitive advantage and customer satisfaction. Companies with fast-moving inventory, frequent price changes, dynamic promotional campaigns, or complex configurations benefit significantly from real-time updates and immediate data availability. However, organizations with stable products, predictable demand patterns, and less time-sensitive operations may succeed with hourly or daily batch synchronization, which reduces technical complexity and infrastructure costs while maintaining operational efficiency.

Complex BOM integration requires mapping ERP manufacturing views to CPQ selling views while maintaining data integrity and business logic. Leading solutions maintain component-level inventory and cost data in ERP while allowing CPQ to manage configuration rules, dependency relationships, and customer-facing product options. Multi-level BOMs need special attention to ensure configuration changes propagate correctly through dependent relationships, alternative components are properly managed, and pricing calculations reflect all configuration dependencies and manufacturing constraints.

Integration platforms must maintain comprehensive audit trails showing all data synchronization activities, user actions, system changes, and business transactions. This includes tracking quote modifications, price overrides, approval workflows, and order handoffs with timestamps and user identification. For regulated industries like pharmaceuticals, aerospace, or financial services, integration logs must meet specific retention and reporting requirements that vary by jurisdiction and may include data encryption, access controls, and periodic compliance reporting.

Performance optimization strategies include intelligent caching of frequently accessed data, asynchronous processing for non-critical updates, load balancing across multiple integration endpoints, and database query optimization. Event-driven architectures typically outperform synchronous API calls for high-volume scenarios by reducing system dependencies and improving scalability. Regular performance testing under realistic load conditions, monitoring of system metrics, and proactive capacity planning identify bottlenecks before they impact users and business operations.

Update frequency depends on your business model, market volatility, and competitive positioning requirements. Manufacturing companies with commodity-based pricing or volatile raw material costs may need hourly cost updates to maintain margin integrity. Service organizations or companies with stable pricing models might update weekly or even monthly. The key is balancing data freshness with system performance and operational complexity. Most successful integrations use event-driven updates triggered by significant cost changes rather than fixed schedules, ensuring critical pricing updates happen immediately while reducing unnecessary system load.

Implementation timelines range from 6-18 months depending on system complexity, organizational readiness, data quality, and integration scope. Simple integrations with standard products and straightforward workflows might complete in 6 months, while complex configurations with custom workflows, multiple ERP instances, and extensive data cleanup require 12-18 months. Total costs typically range from $500K to $3M including software licenses, professional services, infrastructure upgrades, and internal resources. ROI usually realizes within 18-24 months through reduced errors, improved efficiency, faster sales cycles, and enhanced customer satisfaction.

Data quality requires both upfront cleanup and ongoing governance with automated monitoring systems. Pre-integration assessment identifies and corrects data inconsistencies, incomplete records, duplicate entries, and mapping conflicts that could impact integration success. Post-integration monitoring includes automated validation rules, exception reporting, regular data audits, and performance dashboards that track data quality metrics. Successful organizations establish clear data ownership responsibilities, regular review processes, and continuous improvement programs to prevent quality degradation over time and ensure long-term integration success.

Ready to transform your quote-to-cash process with seamless CPQ-ERP integration? Contact MobileForce.ai today to schedule a personalized demonstration and discover how our proven integration platform can eliminate pricing errors, accelerate sales cycles, and drive revenue growth for your organization.