Modern CPQ solutions built to power the next generation of industrial MRO

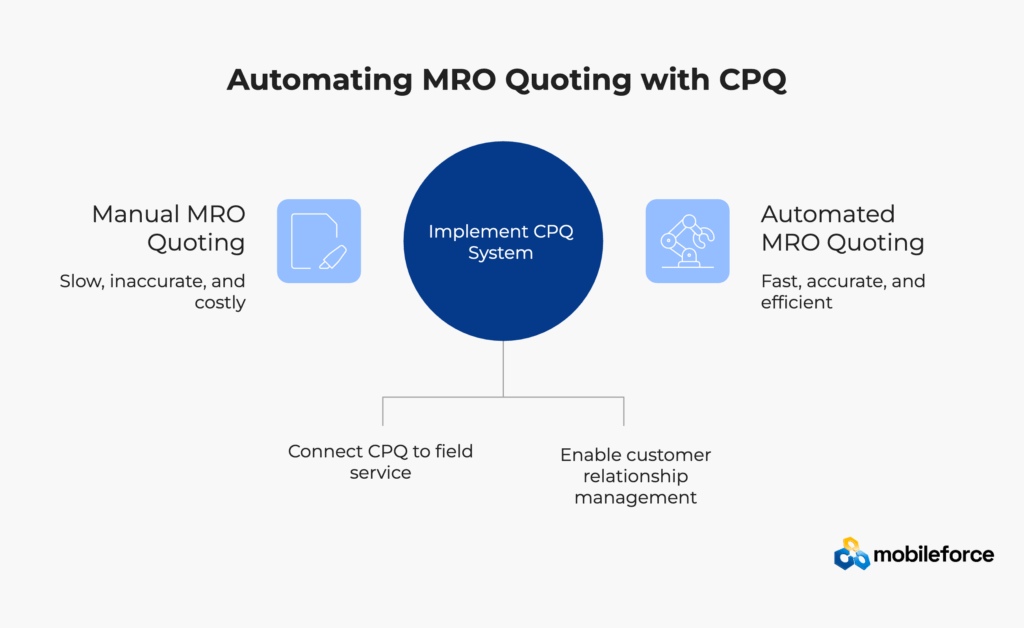

Industrial equipment manufacturers and dealers face unique challenges when quoting maintenance, repair, and operations (MRO) services. Unlike standard product sales, MRO quoting involves complex parts catalogs, warranty considerations, repair-versus-replace decisions, and integration with field service operations. Modern configure price quote software systems designed specifically for maintenance repair operations can automate these processes, reducing quote times by up to 60% while increasing parts attach rates and service contract renewals. The key lies in choosing platforms that integrate CPQ with field service management and provide self-service portals for ongoing customer relationships.

Picture this: A critical piece of mining equipment breaks down on a Friday afternoon. The dealer’s sales rep scrambles to create a quote for emergency repairs, but the pricing system doesn’t account for weekend labor rates, the parts catalog shows conflicting availability, and nobody knows if the warranty covers the failed component. Three hours later, they finally send a quote—only to discover the part number was wrong and the service contract expired last month.

This scenario plays out thousands of times across industrial sectors daily. Equipment downtime costs manufacturers an average of $50,000 per hour according to Aberdeen Research, making fast, accurate MRO quoting critical to business continuity. Yet many companies still rely on manual processes that slow response times and create costly errors.

The solution lies in intelligent quote to cash automation specifically designed for maintenance repair operations. Unlike generic quoting tools, MRO-focused configure price quote platforms understand the unique challenges of aftermarket services, from complex warranty validation to field technician scheduling integration.

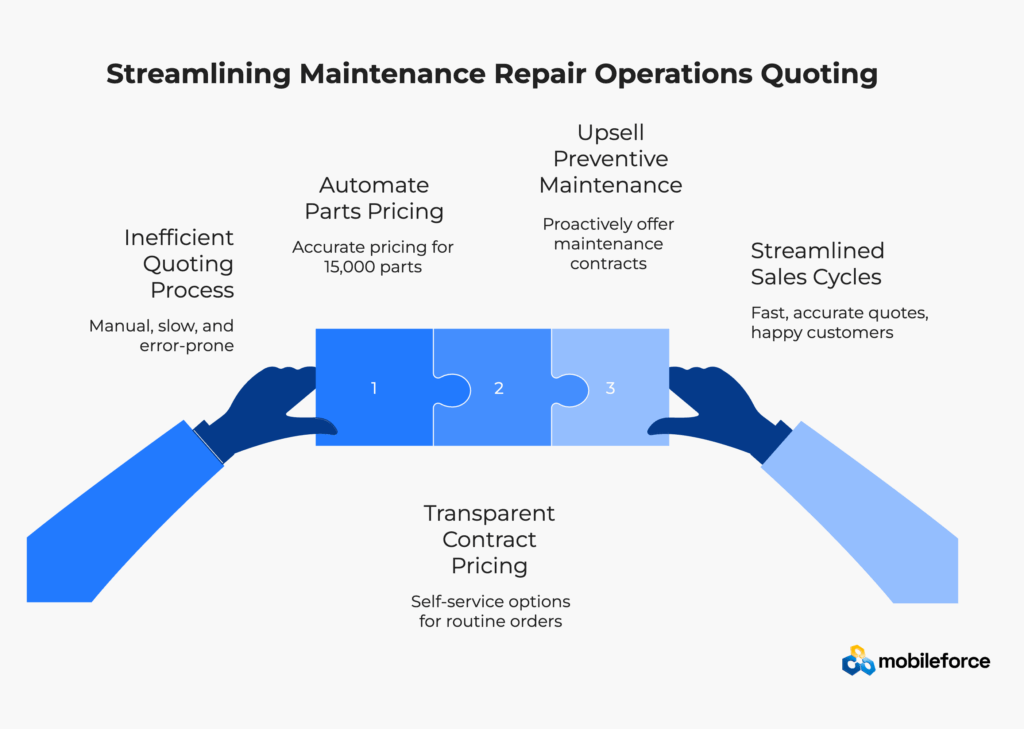

What makes maintenance repair operations quoting different from standard product sales? The complexity stems from variables that don’t exist in typical configure price quote scenarios. A single excavator might have 15,000 parts across multiple suppliers, each with different warranty terms, availability windows, and compatibility requirements. When that excavator needs service, the quote must factor in equipment age, operating hours, maintenance history, and whether repair or replacement makes economic sense.

Consider the pricing realities that MRO teams navigate daily. A hydraulic pump replacement might cost $8,000, but if the machine has 12,000 operating hours and comparable used equipment sells for $45,000, replacement often makes more financial sense for the customer. According to McKinsey’s latest industrial services research, aftermarket services account for up to 60% of industrial equipment lifetime revenue, making accurate maintenance repair operations quoting critical to business success.

The buyer behavior in MRO markets adds another layer of complexity to quote to cash processes. Dealers need instant quotes to compete for emergency repair work, where speed often matters more than perfect optimization. End customers, meanwhile, increasingly expect transparent contract pricing and self-service options for routine parts ordering. Industry data from Aberdeen Group shows that 73% of industrial buyers now prefer self-service options for standard parts purchases.

Traditional quoting systems fall short because they’re designed for configure-to-order manufacturing, not service-intensive aftermarket operations. The result? Manual workarounds, pricing errors, and missed opportunities to upsell preventive maintenance contracts. Equipment downtime costs can reach $22,000 per minute in automotive manufacturing according to McKinsey research, making fast, accurate quotes essential for customer retention.

Understanding how to streamline sales cycles becomes critical when dealing with these high-stakes scenarios where every minute of delay compounds customer frustration and potential revenue loss.

Ready to see how modern CPQ can transform your MRO operations? Schedule a 15-minute demo to explore automated parts pricing and service contract management.

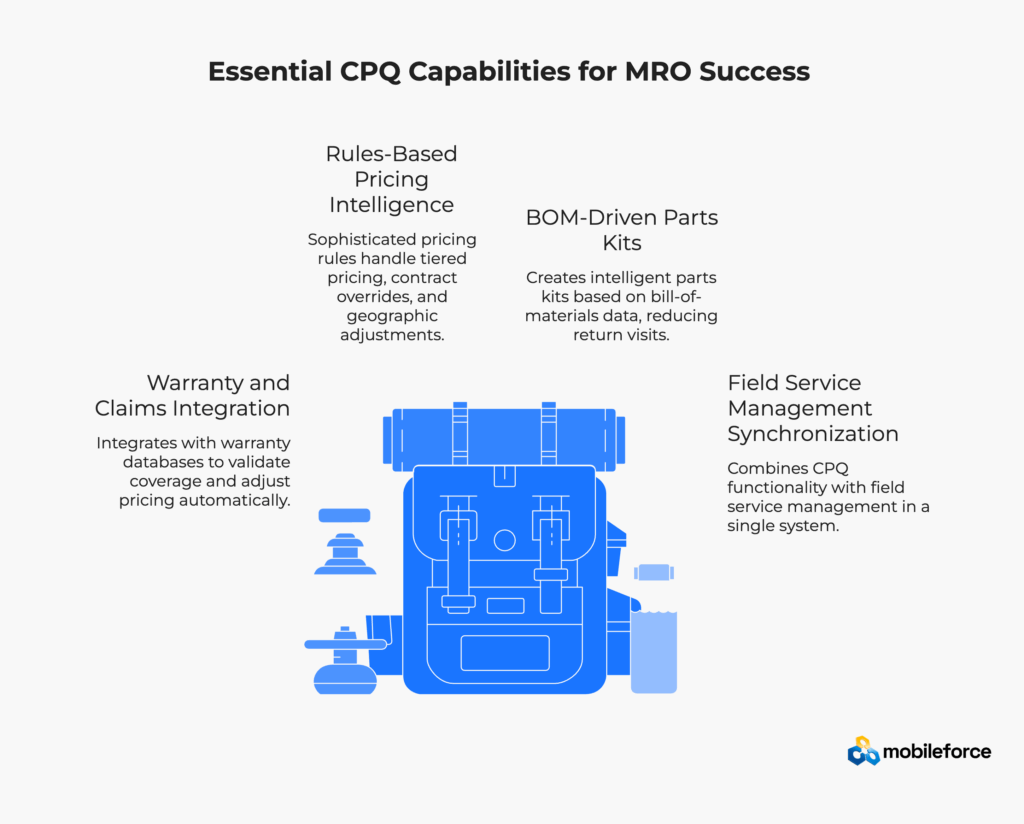

Effective maintenance repair operations configure price quote systems start with sophisticated pricing rules that go far beyond simple cost-plus calculations. The system must handle tiered pricing based on customer segments, contract overrides for preferred dealers, and geographic adjustments for labor rates that vary by region.

For example, a service contract for mining equipment in remote Australian operations requires different labor multipliers than similar work in urban Germany. The quote to cash system should automatically apply these adjustments based on customer location and equipment type, ensuring consistent profitability across markets.

Organizations implementing intelligent pricing strategies can leverage data analytics to optimize these regional adjustments and improve overall margin performance.

One of the biggest differentiators in maintenance repair operations quoting software is the ability to create intelligent parts kits based on bill-of-materials (BOM) data. When a technician identifies a failed hydraulic cylinder, the system should automatically suggest related components that commonly fail together—seals, filters, and hydraulic fluid—creating comprehensive repair kits that reduce return visits.

This capability requires deep integration with parts catalogs and compatibility matrices. The configure price quote system must understand that a 2019 CAT 320 excavator requires different hydraulic seals than a 2021 model, even though the part numbers look similar. This level of parts compatibility intelligence separates professional MRO quoting solutions from generic alternatives.

Industrial equipment warranties are complex, often involving multiple coverage levels, pro-rated terms based on operating hours, and overlapping manufacturer and dealer responsibilities. MRO configure price quote systems must integrate with warranty databases to automatically validate coverage and adjust pricing accordingly.

Research from ServiceMax indicates that warranty claim processing errors cost industrial companies an average of $2.3 million annually in lost reimbursements and customer disputes. Automated warranty validation within the quoting process eliminates these costly mistakes while ensuring accurate customer pricing.

For organizations focused on compliance and regulatory requirements, automated warranty processing also ensures proper documentation and audit trails for regulatory compliance.

The gap between quoting and execution kills profitability in maintenance repair operations. When a quote becomes a work order, the system must automatically reserve parts, schedule technicians with appropriate skills, and provide real-time visibility into job status.

Modern platforms like Mobileforce combine configure price quote functionality with field service management in a single system, eliminating the data handoffs that create errors and delays. When a field technician discovers additional work during a service call, they can create supplemental quotes on-site using mobile devices connected to real-time parts availability.

For organizations exploring field service management solutions, the integration between quoting and FSM modules becomes a critical differentiator in achieving operational efficiency. This unified approach to quote to cash and service delivery ensures seamless customer experiences from initial estimate through job completion.

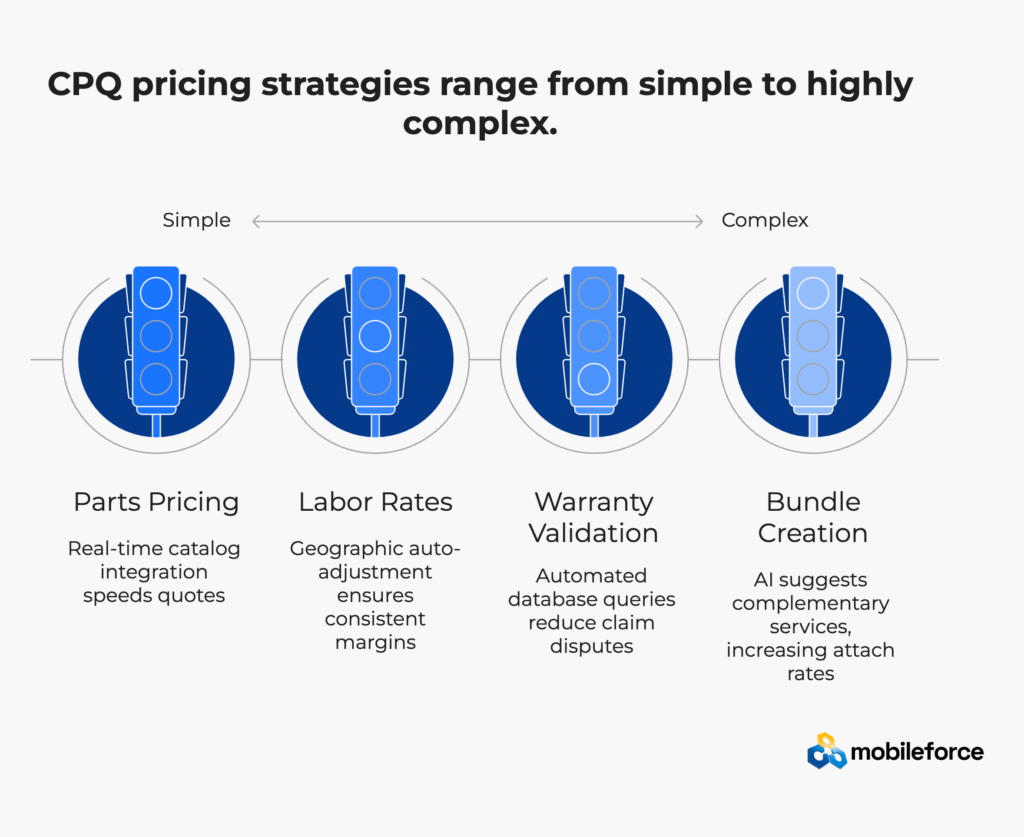

Understanding CPQ pricing strategies becomes critical when dealing with maintenance repair operations scenarios that extend beyond simple product sales. The complexity increases exponentially when you factor in equipment age, warranty status, and total cost of ownership calculations.

One of the most sophisticated aspects of MRO configure price quote systems involves automating repair-versus-replace recommendations. The system must weigh multiple factors: equipment age, remaining useful life, downtime costs, and total cost of ownership.

What factors determine whether to repair or replace equipment? A practical decision rule might look like this:

IF (Equipment_Age > 7 years) AND (Repair_Cost > 40% of Replacement_Value)

THEN Recommend_Replacement

ELSE IF (Downtime_Cost_Per_Hour * Estimated_Repair_Time) > Replacement_Premium

THEN Recommend_Replacement

ELSE Proceed_With_Repair

This logic requires integration with equipment databases, depreciation schedules, and customer-specific downtime cost factors. The quote to cash system presents both options with clear cost justifications, helping customers make informed decisions while protecting margins.

Companies seeking to optimize their sales operations tools often find that automated decision frameworks like these provide significant competitive advantages in complex B2B sales scenarios.

Service contracts in industrial markets often span multiple years with complex escalation clauses, performance guarantees, and renewal options. The configure price quote system must model these relationships accurately, considering inflation adjustments, parts price volatility, and changing labor costs.

How do you price multi-year service contracts? Successful contract pricing also involves margin protection through deal-level guardrails. If a proposed service contract falls below minimum margin thresholds, the system should trigger approval workflows or suggest alternative pricing structures.

Modern maintenance repair operations configure price quote systems excel at creating dynamic bundles that increase average order value while delivering customer value. When quoting a major repair, the system might automatically suggest:

Data from Deloitte’s industrial services practice shows that companies using dynamic bundling strategies in their quoting systems achieve 15-25% higher attach rates on service contracts. This aftermarket revenue optimization becomes crucial for long-term business sustainability.

Understanding how to leverage AI for sales excellence can further enhance these bundling strategies through predictive analytics and customer behavior insights.

Transform your pricing strategy with intelligent automation. See how Mobileforce CPQ handles complex MRO scenarios in a personalized demo.

|

Pricing Component |

Traditional Approach |

Modern CPQ Approach |

Business Impact |

|

Parts Pricing |

Manual lookup, static lists |

Real-time catalog integration |

60% faster quote generation |

|

Labor Rates |

Regional rate cards |

Geographic auto-adjustment |

Consistent margins across markets |

|

Warranty Validation |

Phone calls to manufacturers |

Automated database queries |

95% reduction in claim disputes |

|

Bundle Creation |

Manual add-ons |

AI-suggested complementary services |

20% increase in attach rates |

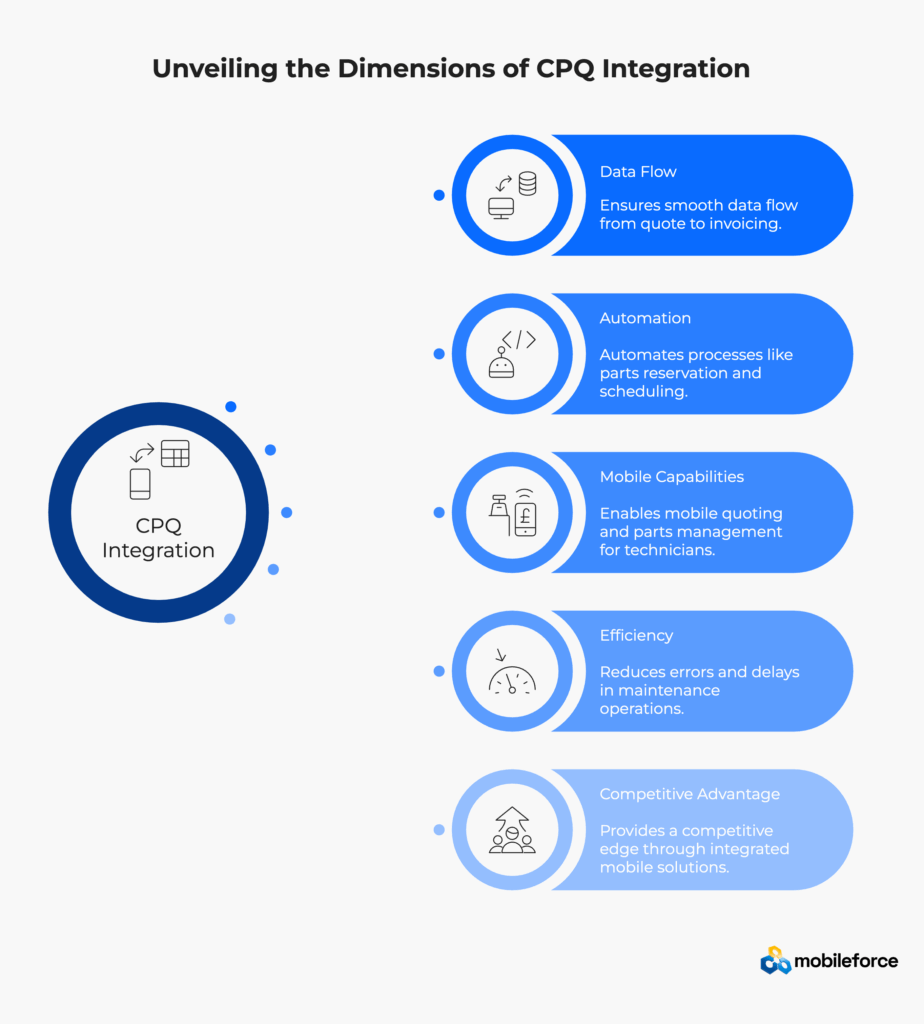

How do you integrate CPQ with existing systems? Successful maintenance repair operations configure price quote implementation requires seamless data flow from initial quote through service completion and invoicing. The ideal architecture connects quoting systems with CRM platforms, ERP systems, parts catalogs, and field service dispatch tools.

When a customer approves a quote, the system should automatically:

This level of integration eliminates the manual handoffs that create errors and delays in traditional maintenance repair operations workflows. Companies implementing integrated quote to cash solutions typically see 30-40% reduction in order processing errors according to Aberdeen Research.

Field technicians need the ability to create quotes, check parts availability, and capture additional work scope while on-site. Modern configure price quote platforms provide mobile applications that work offline, synchronizing data when connectivity returns.

What mobile features do field teams need? Critical mobile capabilities include:

Organizations implementing mobile CPQ capabilities report 25-35% improvement in first-time fix rates due to better on-site quote accuracy and parts availability visibility.

For companies exploring comprehensive mobile revolution in sales, the integration of mobile quoting with field service capabilities represents a significant competitive differentiator.

Most industrial companies operate complex technology ecosystems that require flexible integration approaches. Modern CPQ platforms provide REST APIs and pre-built connectors for common systems like Salesforce, Microsoft Dynamics, and SAP.

The integration strategy should prioritize real-time data synchronization for critical processes like parts availability and customer credit status, while allowing batch updates for less time-sensitive data like parts catalog changes and pricing updates.

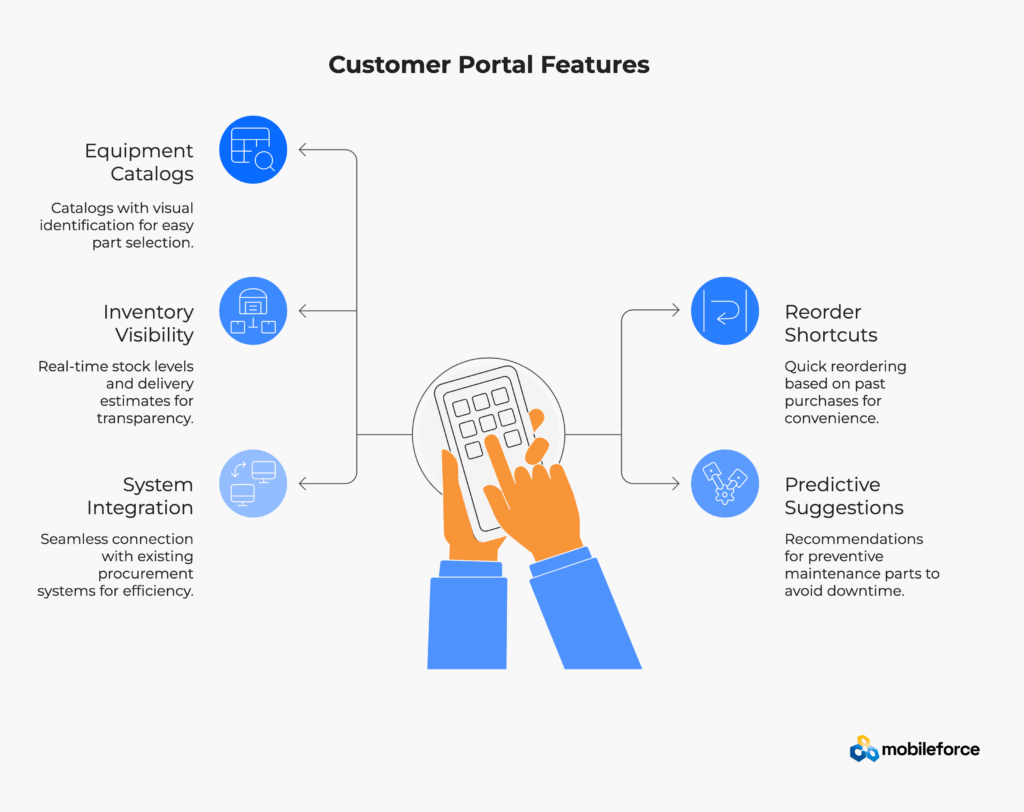

Industrial customers increasingly expect Amazon-like experiences for routine parts ordering. Branded customer portals connected to configure price quote systems enable self-service ordering while maintaining pricing integrity and customer-specific contracts.

What features should customer portals include? Effective portals feature:

Organizations implementing no-code CPQ solutions can deploy these portals without extensive development resources, accelerating time-to-value for both dealers and end customers. Studies show that self-service portals can reduce order processing costs by up to 70% while improving customer satisfaction.

Organizations looking to optimize their RevOps often find that customer self-service capabilities create significant operational leverage while improving the overall customer experience.

Service contracts represent recurring revenue opportunities that many industrial companies under-monetize. Automated renewal processes can increase retention rates while reducing administrative overhead.

How do you automate contract renewals? The configure price quote system should track contract expiration dates, trigger renewal campaigns at appropriate intervals, and enable customers to modify coverage levels or add equipment through self-service interfaces.

Research from the Technology Services Industry Association indicates that companies with automated renewal processes achieve 25% higher retention rates and 40% lower administrative costs compared to manual approaches. This automation becomes critical for aftermarket revenue optimization in competitive markets.

Companies implementing comprehensive subscription management capabilities can further enhance their recurring revenue streams through automated billing and renewal processes.

Ready to enhance your customer experience? Explore Mobileforce’s integrated portal solutions designed for industrial equipment dealers.

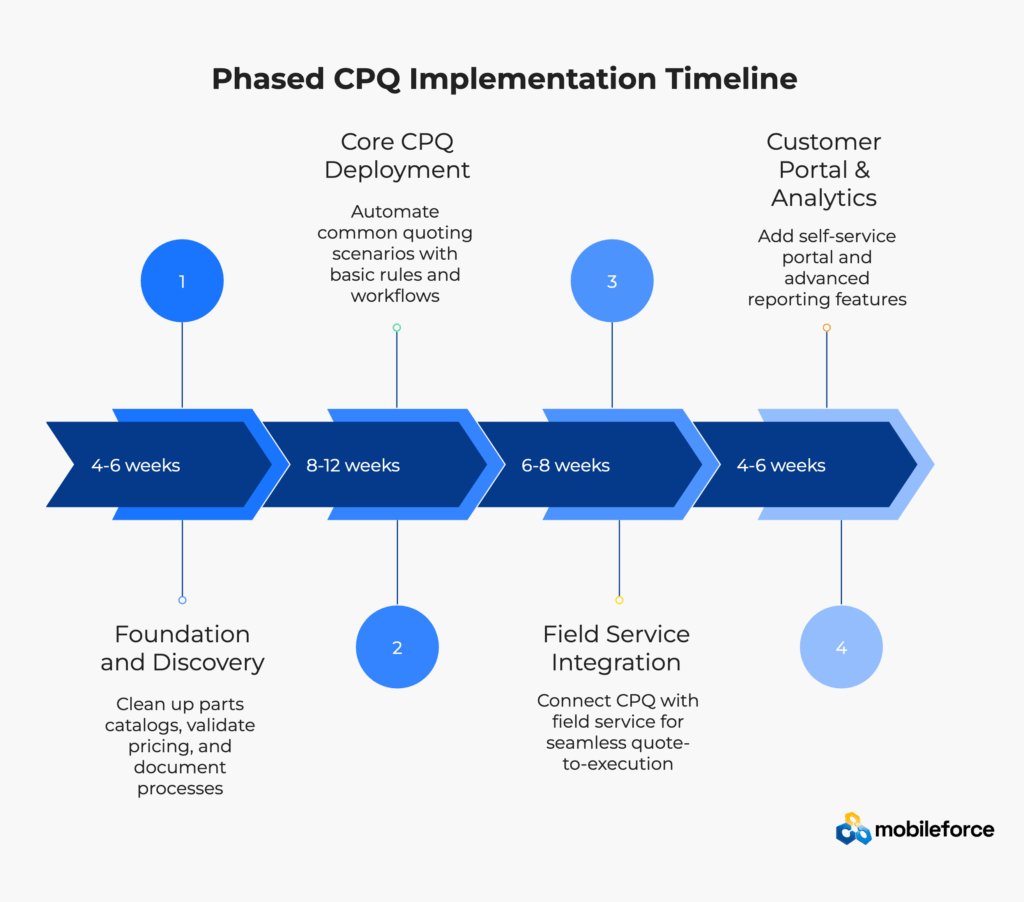

Before implementing configure price quote functionality, companies must clean up parts catalogs, validate pricing data, and document existing quoting processes. This preparatory work prevents garbage-in-garbage-out scenarios that plague rushed implementations.

What should you prepare before CPQ implementation? Key activities include:

The initial deployment focuses on automating the most common quoting scenarios with basic pricing rules and approval workflows. This phase typically covers 60-70% of quoting volume while establishing the foundation for advanced features.

How do you measure Phase 1 success? Success metrics for Phase 1 include:

The second phase connects configure price quote systems with field service operations, enabling seamless handoffs from quote approval to work execution. This integration typically delivers the highest ROI by eliminating manual processes and improving first-time-fix rates.

The final phase adds customer self-service capabilities and advanced reporting features. This stage focuses on driving customer adoption and providing insights for continuous improvement.

Companies taking this phased approach typically achieve faster time-to-value compared to big-bang implementations that attempt to deploy all features simultaneously. Industry data shows phased quote to cash implementations have 75% higher success rates than comprehensive rollouts.

Organizations considering their implementation approach can benefit from understanding key considerations for quote-to-cash solutions to ensure successful deployment and adoption.

Successful maintenance repair operations configure price quote implementations impact multiple operational metrics that directly affect business performance:

Quote-to-Cash Cycle Time: Leading companies achieve 50-70% reduction in average quote-to-invoice cycles through automation and integration. This acceleration improves cash flow and customer satisfaction simultaneously.

First-Time Fix Rate: Improved parts availability visibility and technician mobile access typically increase first-time fix rates by 10-15 percentage points. This metric directly impacts customer satisfaction and operational efficiency.

Parts Attach Rate: Automated bundling and upsell suggestions drive 15-20% increases in parts attach rates on service calls. This aftermarket revenue optimization becomes crucial for long-term profitability.

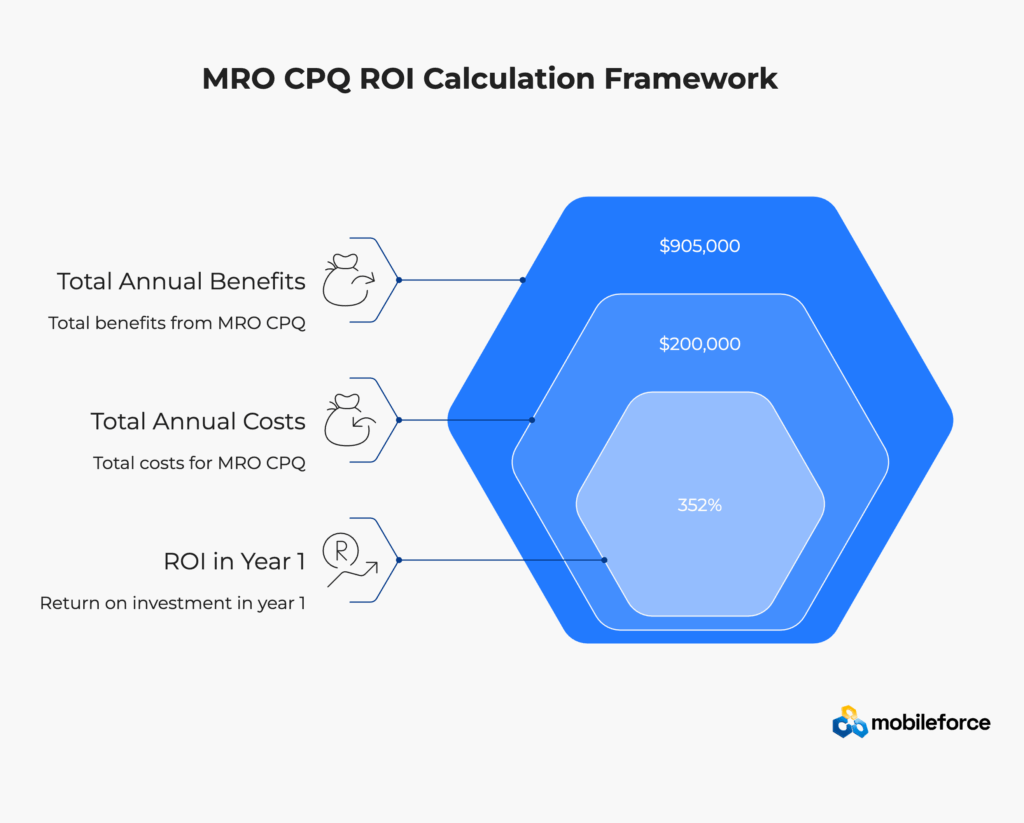

The financial benefits of maintenance repair operations configure price quote systems extend beyond operational efficiency:

What ROI can you expect from MRO CPQ? Revenue Growth: Companies typically see 8-12% increases in aftermarket revenue through improved quote conversion and contract attach rates.

Margin Improvement: Automated pricing rules and margin protection features often deliver 2-3 percentage point margin improvements through better pricing discipline.

Cost Reduction: Reduced manual processes and improved accuracy typically cut administrative costs by 20-30% while freeing up staff for higher-value activities.

A simplified ROI model for maintenance repair operations configure price quote might include:

Benefits (Annual):

Costs (Annual):

ROI: 352% in Year 1

Industry benchmarks suggest that companies implementing comprehensive quote to cash automation typically achieve payback within 8-12 months, with continued benefits scaling over time. cost savings from automation: $180,000

Costs (Annual):

ROI: 352% in Year 1

Calculate your specific ROI potential. Request a customized business case analysis based on your current operations.

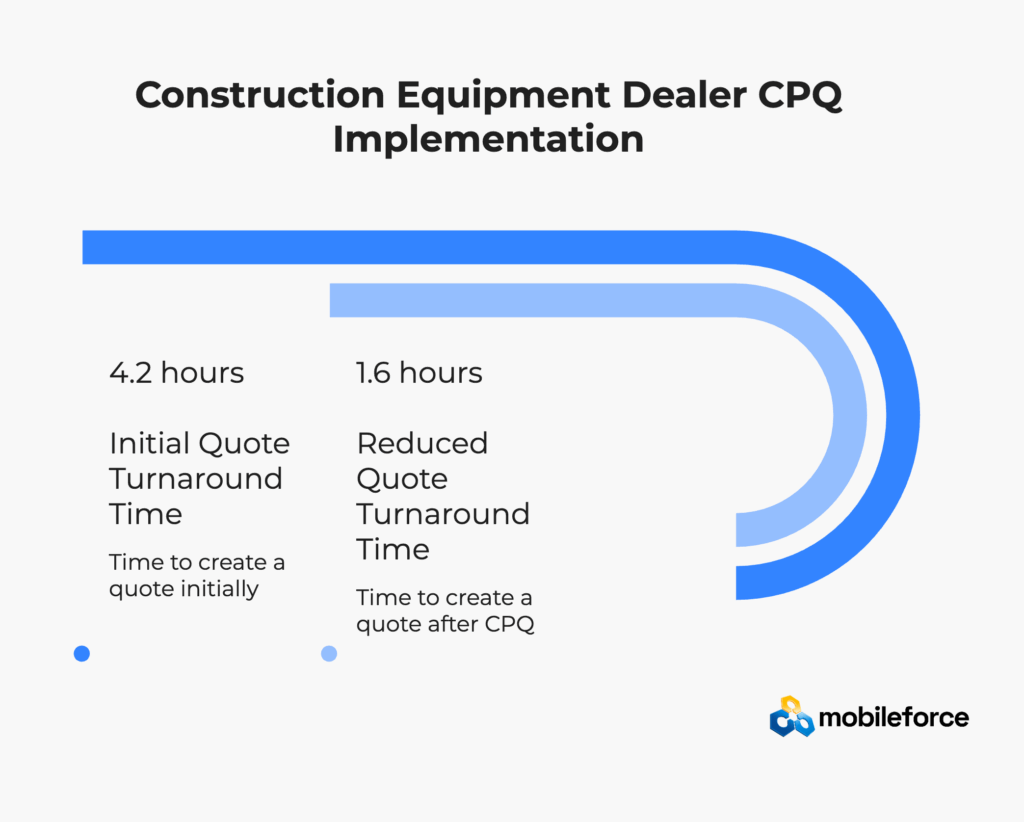

To illustrate the potential impact of MRO-focused configure price quote implementation, consider a hypothetical regional construction equipment dealer with 12 locations facing common industry challenges with inconsistent pricing, long quote turnaround times, and missed opportunities for service contract sales. This conceptual scenario reflects typical issues seen across the construction equipment dealer network.

What problems would manual quoting create? Such a dealer might face:

In this scenario, the dealer would implement a phased configure price quote deployment focusing on:

The implementation would follow industry best practices for maintenance repair operations automation, prioritizing high-volume scenarios first while building toward comprehensive quote to cash integration.

For organizations seeking detailed guidance, exploring three keys to closing deals faster with CPQ can provide valuable insights into implementation prioritization.

How much improvement could CPQ deliver? Based on industry benchmarks, such a dealer might expect:

Industry data suggests such implementations also typically result in improved customer satisfaction scores and increased sales team productivity, with representatives able to handle 35% more quote requests without additional headcount. Aftermarket revenue growth of 20-25% year-over-year demonstrates the potential financial impact of systematic quote to cash optimization, based on aggregated industry performance data.

|

Metric |

Before CPQ |

After CPQ |

Potential Improvement |

|

Quote Turnaround Time |

4.2 hours |

1.6 hours |

62% reduction |

|

Service Contract Attach Rate |

23% |

41% |

78% increase |

|

Pricing Error Rate |

18% |

3% |

83% reduction |

|

Manual Effort per Quote |

85 minutes |

28 minutes |

67% reduction |

When evaluating maintenance repair operations configure price quote solutions, companies should prioritize platforms that offer comprehensive capabilities aligned with industrial requirements.

What features should you prioritize in CPQ software? Key capabilities include:

No-Code Configuration: Business users should be able to modify pricing rules and approval workflows without developer intervention, enabling faster response to market changes and reducing IT dependencies.

Native Field Service Integration: Platforms combining configure price quote with field service management eliminate integration complexity and provide unified customer experiences from estimate through completion.

Mobile-First Design: Field sales teams and technicians need full functionality on mobile devices, including offline capabilities for remote locations. Mobile CPQ capabilities become essential for equipment dealers serving remote industrial sites.

Flexible Pricing Engine: The system must handle complex pricing scenarios including tiered pricing, contract overrides, geographic adjustments, and dynamic bundling rules.

Modern industrial companies operate diverse technology ecosystems requiring flexible integration approaches. Successful configure price quote platforms provide comprehensive connectivity options:

The integration architecture should support both current systems and future technology roadmaps, ensuring long-term quote to cash scalability.

Companies exploring modernizing their CRM and CPQ infrastructure should consider how integration patterns will evolve with emerging technologies and business requirements.

Key factors in vendor selection include multiple dimensions beyond basic functionality:

Implementation Track Record: Look for vendors with specific experience in industrial equipment and maintenance repair operations, not just general configure price quote deployments. Companies can learn from best practices in manufacturing CPQ implementations when evaluating vendor experience.

Support and Training: Complex MRO scenarios require ongoing support and user training programs that go beyond basic platform operation. Evaluate vendor responsiveness and training methodology.

Scalability: The platform should accommodate growth in users, transactions, and complexity without performance degradation or architectural limitations.

Total Cost of Ownership: Consider not just licensing costs but implementation, training, integration, and ongoing maintenance expenses. Understanding CPQ total cost of ownership helps organizations make informed investment decisions that align with long-term business objectives.

Ready to evaluate your options? Compare Mobileforce against your current solutions with our interactive assessment tool.

The industrial equipment aftermarket represents a massive revenue opportunity that many companies fail to fully monetize due to outdated quoting processes and disconnected systems. Modern configure price quote solutions designed specifically for maintenance repair operations can transform these challenges into competitive advantages.

Success requires more than just software deployment. Companies must take a strategic approach that aligns technology capabilities with business processes, ensures seamless integration with existing systems, and provides comprehensive training for users across sales, service, and customer-facing roles.

The companies that embrace MRO-specific configure price quote systems today will establish sustainable competitive advantages in an increasingly service-centric industrial landscape. Those that continue relying on manual processes and disconnected systems risk losing market share to more agile competitors.

Organizations ready to modernize their operations can explore enterprise CPQ solutions designed specifically for complex industrial scenarios, or learn more about quote-to-cash automation strategies that drive sustainable growth.

For companies dealing with legacy systems, understanding Salesforce CPQ end-of-sale implications can help inform strategic decisions about platform migration and future-proofing investments.

Additionally, organizations can explore AI-powered quoting solutions that eliminate common quote-to-cash bottlenecks through intelligent automation.

Ready to transform your MRO operations? Schedule a comprehensive consultation to develop your CPQ strategy and implementation roadmap.

Product configure price quote systems focus on configuring manufactured goods with standard options and pricing rules. Service and aftermarket CPQ handles complex scenarios involving parts catalogs, warranty considerations, labor rates, and service contracts. Aftermarket CPQ must also integrate with field operations and account for equipment lifecycle factors that don’t exist in product sales. The key difference lies in complexity: maintenance repair operations involve thousands of variables, real-time inventory considerations, and field service coordination that standard product quoting cannot handle.

Modern configure price quote systems integrate with warranty databases to automatically validate coverage, calculate pro-rated costs based on equipment age or operating hours, and determine responsibility between manufacturers and dealers. This automation eliminates manual lookup processes and reduces claim disputes by ensuring accurate coverage determination upfront. The system can automatically apply warranty credits, calculate customer responsibility, and generate proper documentation for reimbursement claims, streamlining the entire warranty management process.

Yes, mobile configure price quote capabilities allow field technicians to generate quotes on-site using smartphones or tablets. The system can check real-time parts availability, reserve inventory for approved quotes, and even process orders for immediate delivery to job sites. Offline functionality ensures technicians can work in remote locations without internet connectivity, with automatic synchronization when connection returns. This capability improves first-time fix rates and customer satisfaction while reducing return visits.

Implementation timelines vary based on complexity and scope, but most companies see initial value within 12-16 weeks using a phased approach. Core quoting functionality typically deploys in 8-12 weeks, with field service integration and customer portals adding another 6-8 weeks. This phased approach delivers faster time-to-value than attempting to implement all features simultaneously. Companies with clean data and well-defined processes can sometimes achieve faster deployment, while complex integrations may extend timelines.

Key performance indicators include quote turnaround time, pricing accuracy, service contract attach rates, first-time fix rates, and overall aftermarket revenue growth. Operational metrics like manual effort per quote and user adoption rates provide insights into system effectiveness and areas for improvement. Financial metrics should track margin improvement, cost reduction, and return on investment to demonstrate business value. Leading companies also monitor customer satisfaction scores and sales team productivity to ensure the implementation delivers comprehensive benefits.

Integration eliminates manual handoffs between sales and service teams, automatically reserves parts when quotes are approved, schedules technicians with appropriate skills, and provides real-time visibility into job status. This seamless flow reduces errors, improves customer communication, and increases first-time fix rates. The integration enables technicians to create supplemental quotes on-site, ensures accurate parts availability, and streamlines the entire quote to cash to service process. Companies typically see 20-30% improvement in operational efficiency through this integration.

Most companies achieve 200-400% ROI in the first year through reduced labor costs, improved pricing accuracy, increased attach rates, and faster quote-to-cash cycles. Specific results vary based on current process efficiency and implementation scope, but payback periods typically range from 6-12 months. Leading implementations deliver quote time reductions of 40-60%, margin improvements of 2-3 percentage points, and aftermarket revenue increases of 8-15%. The key is measuring both operational improvements and financial impact to capture total value.

Advanced configure price quote platforms can automate repair-versus-replace recommendations using configurable business rules that consider equipment age, repair costs, downtime impacts, and total cost of ownership. The system presents both options with clear cost justifications, helping customers make informed decisions while protecting margins. This capability requires integration with equipment databases, depreciation schedules, and customer-specific factors. The automation improves decision quality while reducing the expertise required from individual sales representatives.