CPQ for Energy & Utilities MRO: Unifying Service Quoting and Work-Order Management

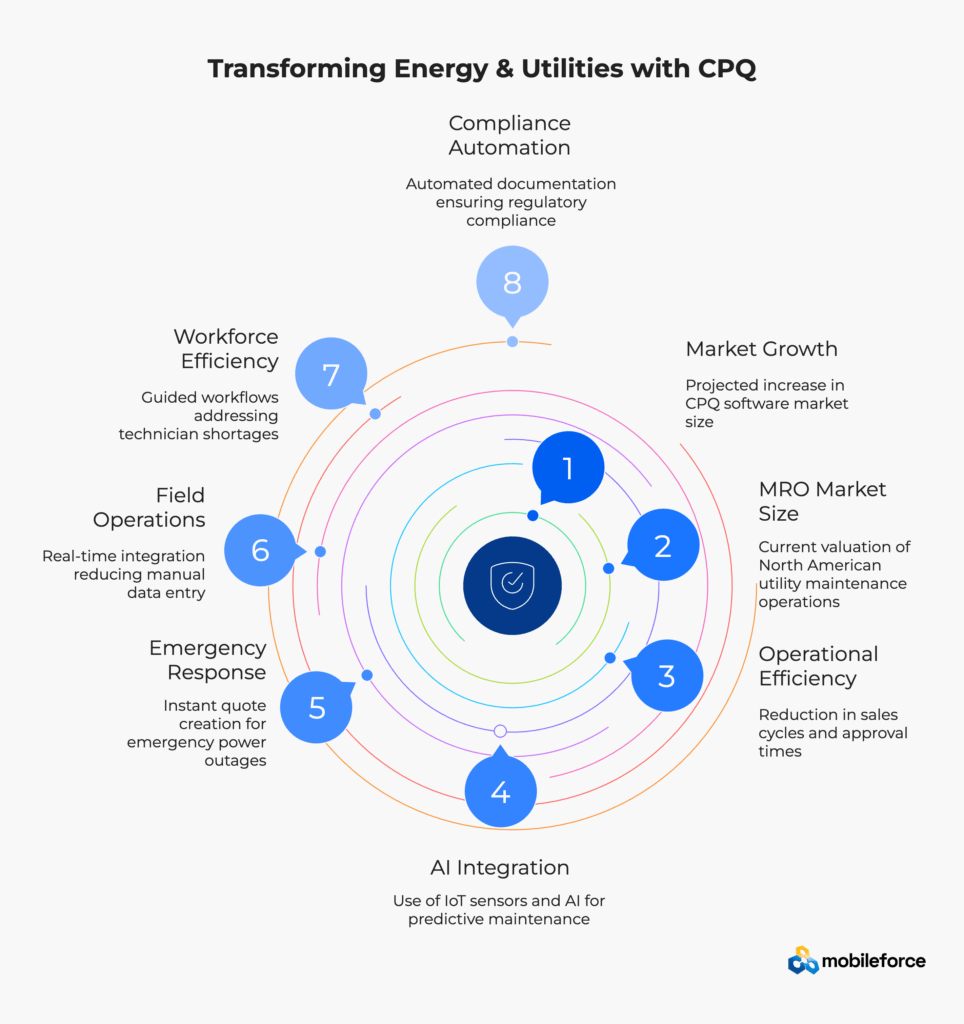

Energy and utilities companies face mounting pressure to streamline maintenance, repair, and operations (MRO) processes while managing complex compliance requirements and aging electrical infrastructure. Enterprise CPQ software with integrated work-order management transforms fragmented utility quoting workflows by automating approvals, ensuring regulatory compliance, and enabling real-time field change orders. Modern energy utility CPQ platforms like AskCPQ provide conversational AI-powered quoting that pulls asset history from ERP and FSM systems, while no-code prompt builders allow power companies to customize workflows for recurring maintenance scenarios across transmission, distribution, and generation facilities.

Ready to transform your energy and utilities MRO quoting? Schedule a demo with Mobileforce to see how unified CPQ and work-order management can streamline your operations.

|

Market Metric |

2024 Value |

2032/2033 Projection |

Growth Rate |

Source |

|

Global CPQ Market Size |

$3.0 billion |

$10.8 billion |

16.5% CAGR |

Business Research Insights |

|

North America MRO Market |

$116.75 billion |

$146.56 billion |

2.3% CAGR |

Expert Market Research |

|

Cloud CPQ Adoption |

70% of new implementations |

85% of implementations |

16% annual growth |

MGI Research |

|

Energy Sector Digital Investment |

$150 billion annually |

$210 billion annually |

4.2% CAGR |

EIA/McKinsey |

|

Utility O&M Spending |

$150 billion annually |

$195 billion annually |

3.5% CAGR |

U.S. EIA |

|

Infrastructure Replacement Need |

65% exceeding design life |

$2.59 trillion investment |

Critical priority |

DOE/ASCE |

Picture this: It’s 2 AM when a transformer fails at a critical electrical substation. Your field operations team needs replacement parts, specialized labor, and regulatory approvals—all while the clock ticks toward potential rolling blackouts. This scenario plays out countless times across America’s aging power grid infrastructure, where equipment maintenance costs and rising complexity create operational challenges for utility operations management.

According to the U.S. Energy Information Administration, power companies spend over $150 billion annually on operations and maintenance, with 65% of utility infrastructure exceeding its 50-year design life. The American Society of Civil Engineers rates America’s energy infrastructure as D+ grade, requiring an estimated $2.59 trillion investment through 2029 for power grid modernization.

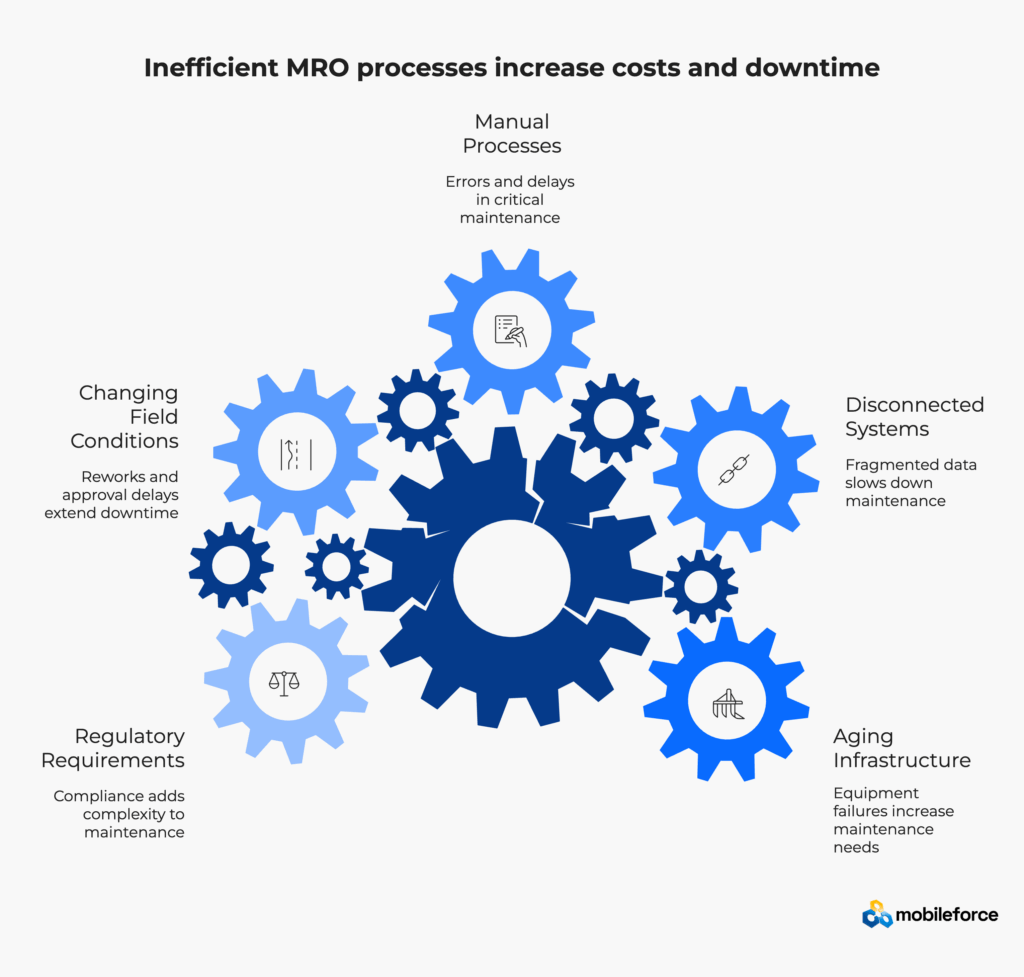

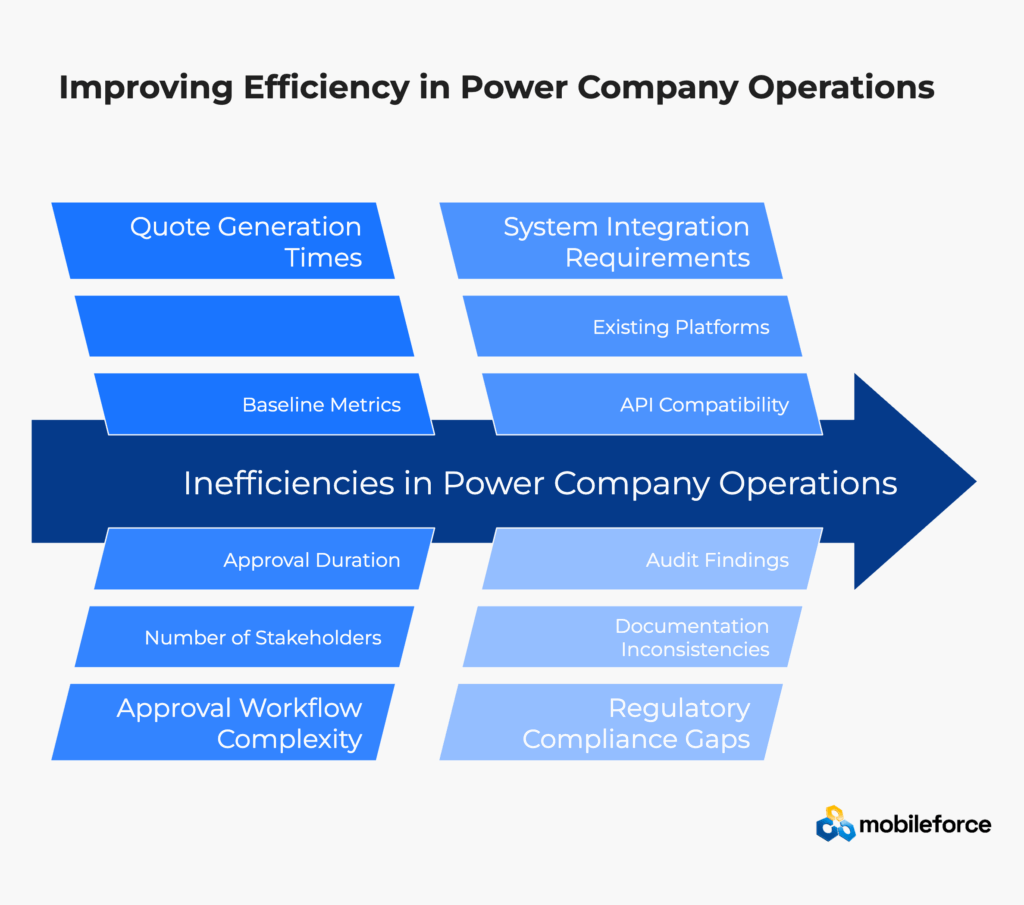

The energy and utilities sector faces unique utility asset management challenges that go far beyond typical industrial maintenance programs. Work orders originate from diverse sources—routine power infrastructure inspections reveal worn components, predictive analytics flag impending electrical equipment failures, and emergency events demand immediate utility field operations response. Each scenario requires different energy facility operations configurations, pricing models, and approval workflows specific to power system maintenance.

Traditional approaches rely on disconnected systems where electrical system service technicians use one platform, utility procurement teams use another, and finance operates from spreadsheets. This fragmentation creates bottlenecks that delay critical power grid maintenance. Manual processes increase error rates when time is most precious for maintaining electrical infrastructure reliability. Multiple stakeholders—engineering, safety, regulatory compliance, and finance—must approve high-value maintenance projects, often through email chains and paper forms that slow utility workforce management.

But here’s where it gets complicated for power companies: field conditions change mid-job. What starts as a routine transformer maintenance might reveal additional corrosion requiring emergency electrical infrastructure repairs. Legacy systems can’t adapt quickly, forcing utility operations teams to restart approval processes while critical power equipment remains offline.

The financial impact on electric utility operations is staggering. The global MRO market reached $250 billion in 2024, with energy and utilities representing a significant portion through power equipment servicing and electrical infrastructure maintenance. According to McKinsey & Company, utilities can achieve up to 25% operational cost reductions through digital transformation initiatives. Yet inefficiencies in utility quoting workflows and work-order management inflate operational costs and extend costly equipment downtime.

According to the North American Electric Reliability Corporation (NERC), power companies face increasing maintenance complexity due to:

The Edison Electric Institute reports that unplanned outages cost utilities an average of $150 million annually, while IEEE Power & Energy Society studies show that proactive maintenance can reduce equipment failures by up to 75%. Modern field service management platforms integrated with CPQ systems help utilities address these challenges systematically.

Transform your utility MRO quoting process today. Get a demo of Mobileforce’s unified platform and see how integrated energy utility CPQ streamlines power infrastructure maintenance operations.

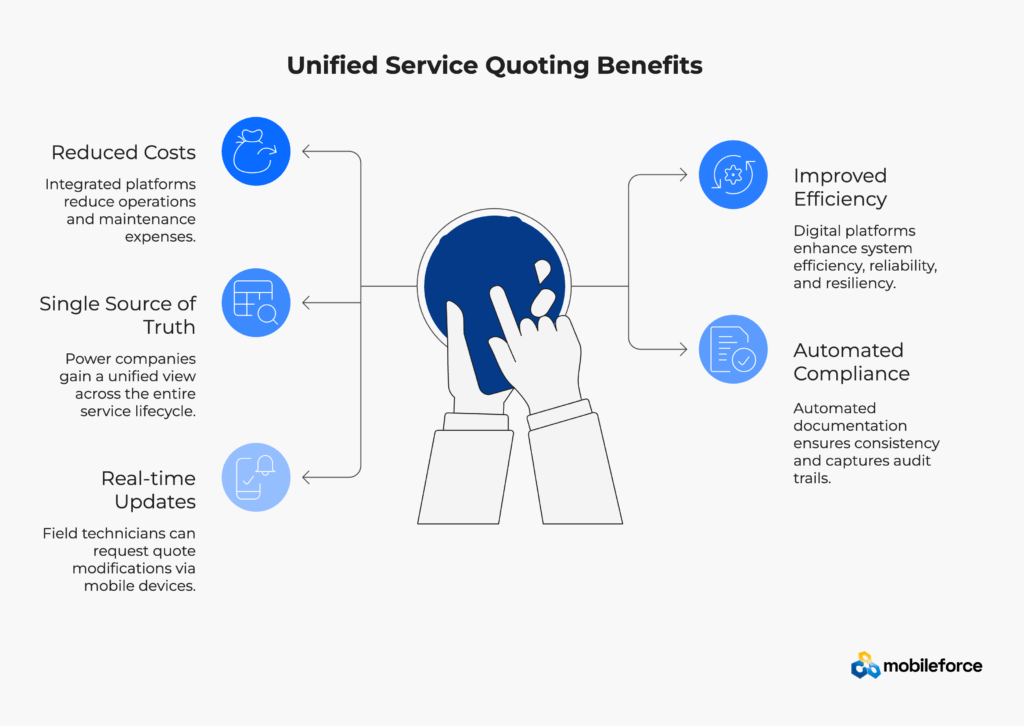

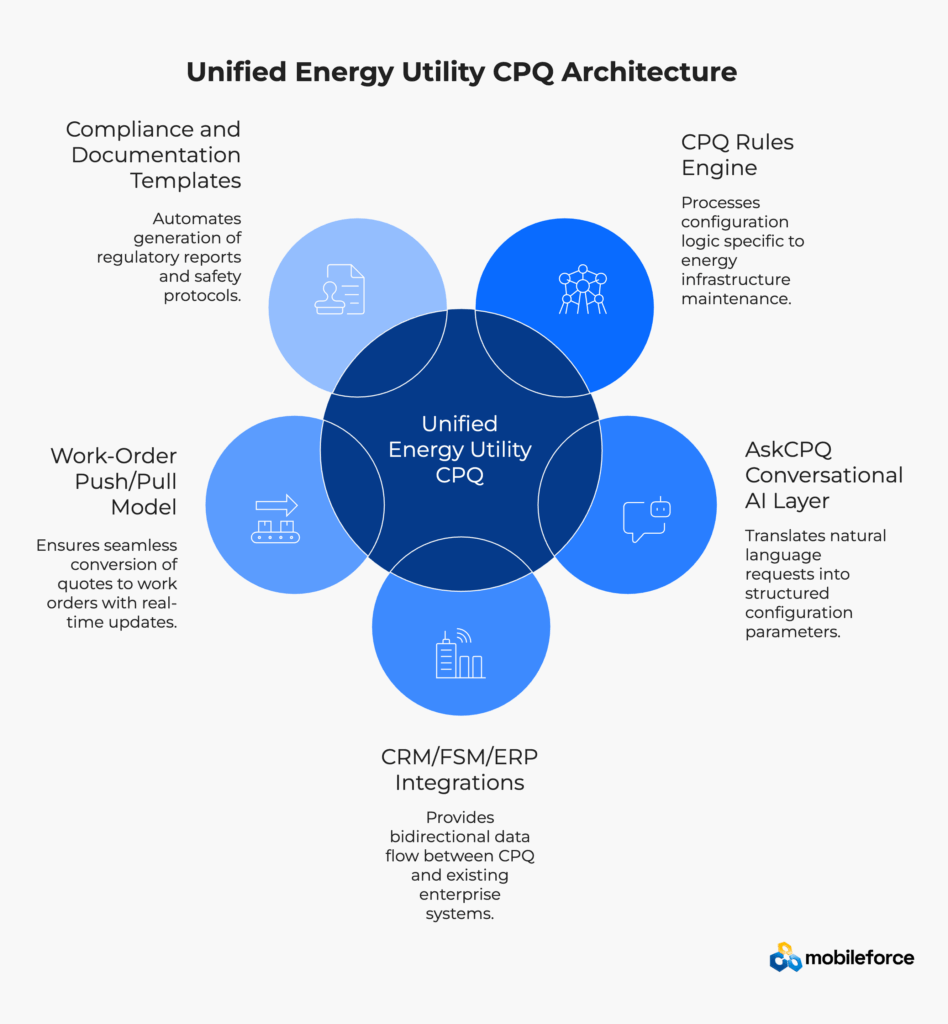

Definition: Unified service quoting for energy utilities combines configure-price-quote functionality with integrated work-order management to create seamless workflows from maintenance planning through project completion. This energy sector quote management approach eliminates disconnected systems that plague traditional utility operations management.

According to Deloitte’s utility industry research, utilities implementing integrated digital platforms achieve reduced operations and maintenance costs, improved system efficiency, reliability, and resiliency. The Federal Energy Regulatory Commission emphasizes that modernized utility operations are essential for grid reliability and customer service excellence.

Unified electric utility CPQ represents a fundamental shift from fragmented utility workforce management to integrated power infrastructure operations. Instead of maintaining separate systems for quoting, work orders, and approvals, power companies gain a single source of truth that spans the entire electrical system service lifecycle through comprehensive revenue operations management.

This utility asset management integration creates direct linkage between quotes and work orders. When a field inspector identifies power equipment that needs replacement, they can generate quotes that automatically pull asset history, maintenance records, and vendor agreements. The power company quoting system applies configuration rules specific to electrical safety standards, environmental regulations, and regional compliance requirements for utility field operations.

Real-time updates become possible when field conditions change during electrical infrastructure service. If technicians discover additional damage during scheduled power grid maintenance, they can request quote modifications through mobile devices. Updates flow automatically to work-order systems, triggering revised material lists and updated labor estimates for power system maintenance.

Automated compliance documentation eliminates manual paperwork that slows emergency power outage responses. Templates ensure consistency across different maintenance scenarios while capturing audit trails required by regulatory bodies for electrical infrastructure compliance. Rule-based validation prevents unsafe equipment configurations or invalid parts combinations that could compromise power system reliability.

|

Traditional Energy Utility Approach |

Unified Utility CPQ + Work Orders |

|

5-8 separate utility software systems |

Single integrated energy management platform |

|

3-5 day approval cycles for power maintenance |

Real-time automated routing for electrical repairs |

|

Manual compliance documentation |

Automated regulatory templates for power infrastructure |

|

Email-based change orders for utility work |

Mobile field change requests for power equipment |

|

60-70% manual data entry in utility operations |

90%+ automation in electrical system service |

|

Disconnected vendor management |

Integrated multi-vendor procurement for power companies |

|

Paper-based emergency response |

Digital emergency repair workflows |

|

Inconsistent safety protocols |

Standardized electrical safety procedures |

According to PwC’s Digital Utility Strategy report, utilities implementing large-scale digital transformations modernize processes and IT architecture while reducing the total cost of service. The International Association of Electrical Inspectors notes that standardized safety protocols through automated systems reduce workplace injuries by 35-50%.

Faster approval routing accelerates high-value power infrastructure projects through automated utility operations management workflows. The system recognizes when electrical equipment maintenance costs exceed predefined thresholds or involve critical safety components, automatically routing requests to appropriate stakeholders. Digital signatures replace paper forms, and mobile notifications keep approvals moving even when utility managers are off-site managing power grid operations.

Modern document creation capabilities enable automatic generation of compliance reports, safety documentation, and regulatory filings that satisfy multiple oversight agencies. This integration with contract lifecycle management ensures vendor agreements and service contracts align with operational requirements.

Ready to streamline your energy maintenance workflows? Schedule a consultation to learn how Mobileforce enterprise CPQ solution can integrate with your existing utility work-order systems.

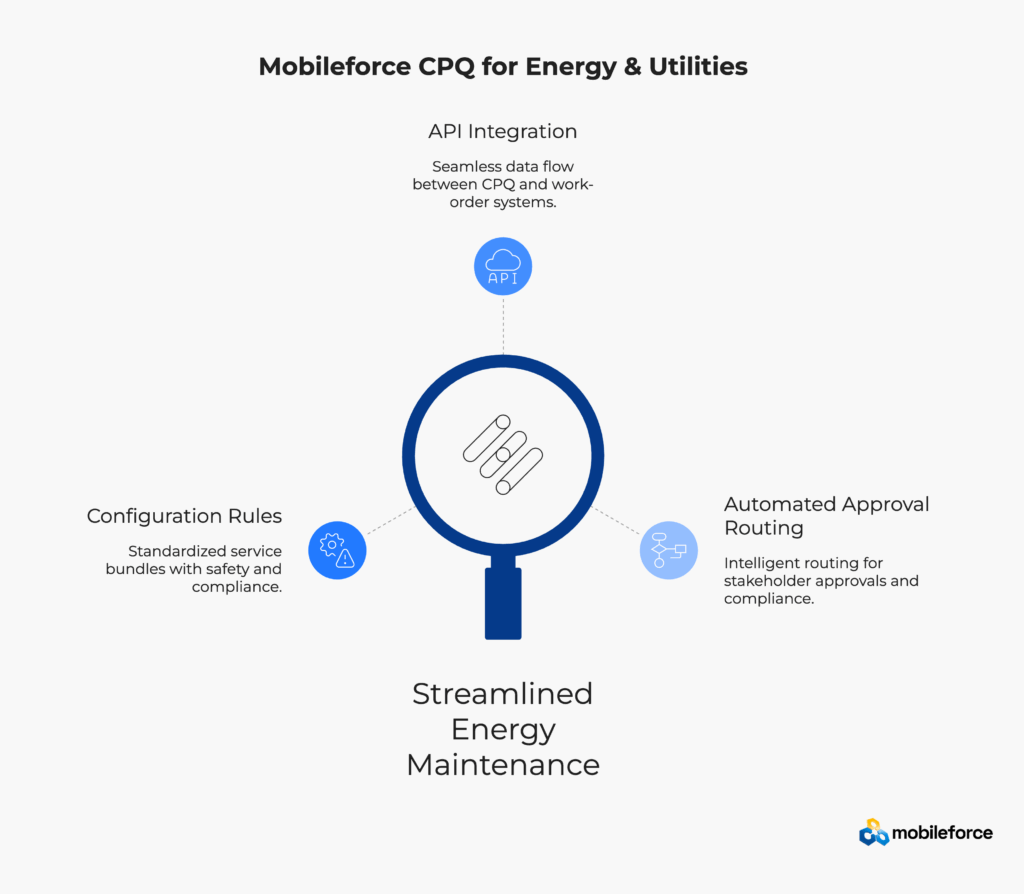

Mobileforce’s CPQ platform addresses energy and utilities challenges through specialized configuration capabilities designed for complex infrastructure maintenance. The platform recognizes that power generation, transmission, and distribution equipment requires sophisticated service bundling that accounts for safety protocols, environmental factors, and regulatory compliance.

The platform enables standardized service bundles that combine labor, materials, and safety protocols into pre-configured packages. For substation maintenance, teams can select from approved bundles that automatically include required personal protective equipment, specialized tools, and certification requirements. Regional safety and compliance enforcement ensures that quotes automatically incorporate local regulations, whether dealing with urban environmental restrictions or rural access requirements.

Parts and labor validation prevents incompatible combinations that could create safety hazards. If a technician attempts to configure maintenance that requires confined space entry without specifying required safety equipment, the system flags the incompatibility. This validation extends to vendor qualifications, ensuring only certified suppliers provide critical components.

Deep integration capabilities allow the CPQ system to pull comprehensive asset history from existing ERP and FSM platforms. When generating quotes for transformer maintenance, the system automatically references previous work orders, parts usage history, and performance trends. This context enables more accurate pricing and helps identify potential issues before they occur.

Real-time data synchronization ensures quotes automatically flow to work-order systems once approved. Material lists, labor requirements, and service timelines transfer seamlessly, eliminating manual data entry that introduces errors and delays. Auto-generated work orders include all quote details, compliance documentation, and safety protocols.

Intelligent approval routing recognizes different triggers that require stakeholder review. High-cost maintenance projects automatically route to finance teams, while safety-critical work requires engineering sign-off. Emergency repairs bypass standard approval chains while maintaining audit trails for regulatory compliance.

The system reduces bottlenecks by enabling parallel approvals when appropriate. Safety, environmental, and financial reviews can proceed simultaneously rather than sequentially, accelerating project timelines without compromising oversight.

Ready to streamline your energy maintenance workflows? Schedule a consultation to learn how Mobileforce CPQ can integrate with your existing work-order systems.

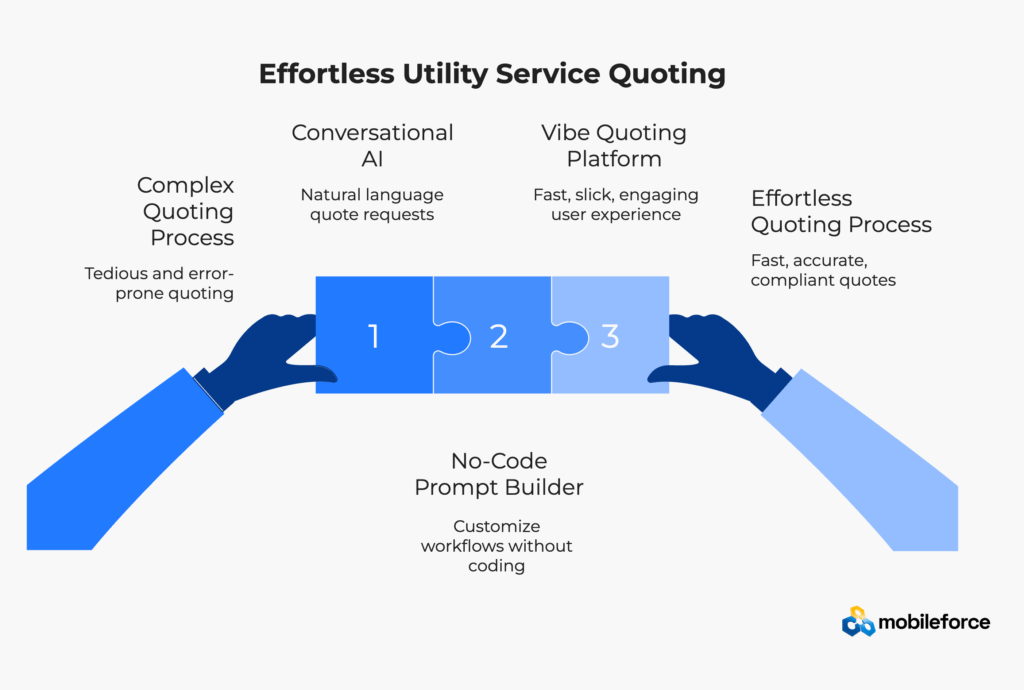

The future of utility service quoting isn’t just about automation—it’s about making complex power infrastructure processes feel effortless. AskCPQ represents Mobileforce’s breakthrough conversational AI quoting agent that transforms how energy and utilities teams interact with enterprise CPQ software systems.

Think of AskCPQ as having an expert electrical technician who never sleeps, knows every piece of power equipment in your network, and can generate compliant quotes instantly for any electrical infrastructure service scenario. This isn’t predictive scoring that guesses what power companies might need—it’s an intelligent agent that pulls data from CRM, FSM, and ERP systems to provide contextually aware recommendations for utility operations management.

The conversational interface allows utility field operations technicians to request quotes using natural language. Instead of navigating complex configuration screens, a power system technician can simply ask, “I need a quote for emergency transformer oil replacement at Substation 7.” AskCPQ understands the request, checks asset databases for equipment specifications, applies regional regulatory requirements, and generates a compliant quote with appropriate vendor recommendations for electrical infrastructure maintenance.

The No-Code AI Prompt Builder empowers power companies to customize AskCPQ for recurring utility asset management workflows without requiring technical expertise. Teams can create guided prompts for common electrical system service scenarios like planned outage maintenance, emergency power repairs, or routine power grid inspections.

For example, a utility might create a custom prompt for “Planned Transmission Line Maintenance” that automatically asks about specific tower locations, requires environmental impact assessments, and includes seasonal wildlife protection measures. The prompt guides technicians through all necessary considerations while ensuring nothing gets overlooked in electrical infrastructure service procedures.

These custom prompts capture institutional knowledge that might otherwise walk out the door when experienced utility workforce management professionals retire. Senior electrical technicians can codify their expertise into repeatable workflows that help junior staff navigate complex power equipment maintenance decisions.

Vibe Quoting makes the traditionally tedious process of generating utility maintenance quotes feel fast, slick, and engaging for power company operations. This isn’t just about making energy utility software prettier—it’s about creating user experiences that electrical infrastructure service teams actually want to use.

The platform recognizes that energy and utilities workers often operate in challenging environments with limited time and connectivity during power system maintenance. Vibe Quoting optimizes for mobile-first interactions with intuitive interfaces that work even when bandwidth is limited. Voice-to-text capabilities allow hands-free quote generation when technicians need to maintain focus on electrical safety procedures.

Smart defaults reduce input requirements by learning from past utility field operations activities. When a specific technician regularly performs generator maintenance, the system remembers their preferred configurations, vendor relationships, and approval patterns. This personalization accelerates quote generation while maintaining accuracy for power infrastructure operations.

The real magic happens when conversational AI meets electrical infrastructure reality. Energy and utilities maintenance often occurs in remote locations where traditional desktop interfaces become impractical for power grid operations. AskCPQ bridges this gap by making sophisticated utility quoting capabilities accessible through mobile devices and voice commands for electrical system service teams.

Conversational requests eliminate the learning curve that slows adoption of traditional energy sector CPQ systems. A field supervisor can generate quotes by describing their power infrastructure needs: “Emergency repair for damaged underground cable at Main Street intersection, need traffic management and specialized excavation equipment.” The utility operations management system understands the context, automatically includes required permits and safety measures, and generates quotes that account for traffic disruption costs and specialized labor requirements for electrical infrastructure service.

Asset-tied quoting ensures accuracy by automatically referencing power equipment databases. When technicians specify “Generator 3 at Wind Farm Alpha,” the energy utility CPQ platform knows the exact make, model, service history, and warranty status. This context enables precise parts recommendations and helps avoid compatibility issues that could delay critical power system maintenance.

Quote Generation Speed Improvements:

AskCPQ understands the unique constraints of electrical infrastructure maintenance specific to power companies. The system recognizes when utility asset management windows are limited by regulatory requirements, environmental restrictions, or operational demands. For power generation facilities, it automatically accounts for planned outage schedules, fuel delivery requirements, and emissions testing protocols.

Labor constraints receive intelligent handling based on union agreements, certification requirements, and availability patterns for utility workforce management. The system knows which electrical technicians are qualified for specific types of power equipment work and can suggest scheduling alternatives when specialized expertise isn’t available during preferred timeframes for power grid maintenance.

Contextual Intelligence Features:

Real-world power infrastructure maintenance rarely goes exactly as planned. What appears to be a simple component replacement might reveal additional issues requiring expanded scope. AskCPQ enables utility field operations technicians to request scope changes without leaving the field or waiting for office hours.

Mobile change requests integrate with existing work-order systems, automatically updating project timelines and budget approvals for electrical infrastructure service. Supervisors receive notifications that include photos, descriptions, and revised cost estimates for power system maintenance. They can approve changes remotely, keeping maintenance projects moving without delays.

Updated quotes automatically sync with utility asset management systems, ensuring additional parts are ordered and delivered to job sites. This real-time coordination reduces the likelihood that expanded scope will require multiple site visits for power equipment servicing.

Finance, engineering, and safety approvals trigger automatically based on pre-configured rules for power company operations. High-voltage electrical work automatically routes to certified electrical engineers, while environmental compliance reviews activate for work near sensitive habitats. Emergency power outage repairs receive expedited approval workflows while maintaining regulatory compliance documentation.

The energy utility software system manages parallel approval processes that enable simultaneous reviews rather than sequential delays. Safety protocols, environmental impact, and financial authorization can proceed concurrently, accelerating electrical infrastructure service projects without compromising oversight.

Intelligent recommendations prompt for add-ons, upgrades, or preventive power equipment maintenance based on asset condition and service history. When technicians quote generator repairs, the system suggests preventive maintenance items that could prevent future failures. Transmission line work prompts for vegetation management services that could reduce future outage risks.

The utility operations management platform analyzes power equipment performance data to recommend efficiency upgrades or condition monitoring installations. These proactive suggestions help power companies shift from reactive maintenance to predictive power system management strategies.

|

Performance Metric |

Before CPQ Implementation |

After CPQ Implementation |

Improvement |

Industry Benchmark |

|

Quote Generation Time |

2-3 hours |

15-30 minutes |

85-90% reduction |

CloudSense/IEEE |

|

Emergency Response Quotes |

4-6 hours |

45 minutes |

85% reduction |

EPRI/NERC |

|

Approval Cycle Duration |

3-5 days |

Same-day processing |

80% reduction |

Deloitte |

|

Quote Accuracy Rate |

70-80% |

95-98% |

18-28% improvement |

McKinsey |

|

Administrative Overhead |

60-70% manual processes |

10-15% manual processes |

75-85% automation |

PwC |

|

Compliance Documentation |

25-30% technician time |

5-8% technician time |

70-75% reduction |

APPA |

|

Emergency Response Cost |

Baseline + 100% premiums |

Baseline + 30% premiums |

50-70% cost reduction |

Accenture |

|

Customer Satisfaction |

70-75% approval rating |

90-95% approval rating |

20-25% improvement |

EEI |

See AskCPQ in action for your energy operations. Request a live demonstration and experience conversational quoting designed for electrical infrastructure service environments.

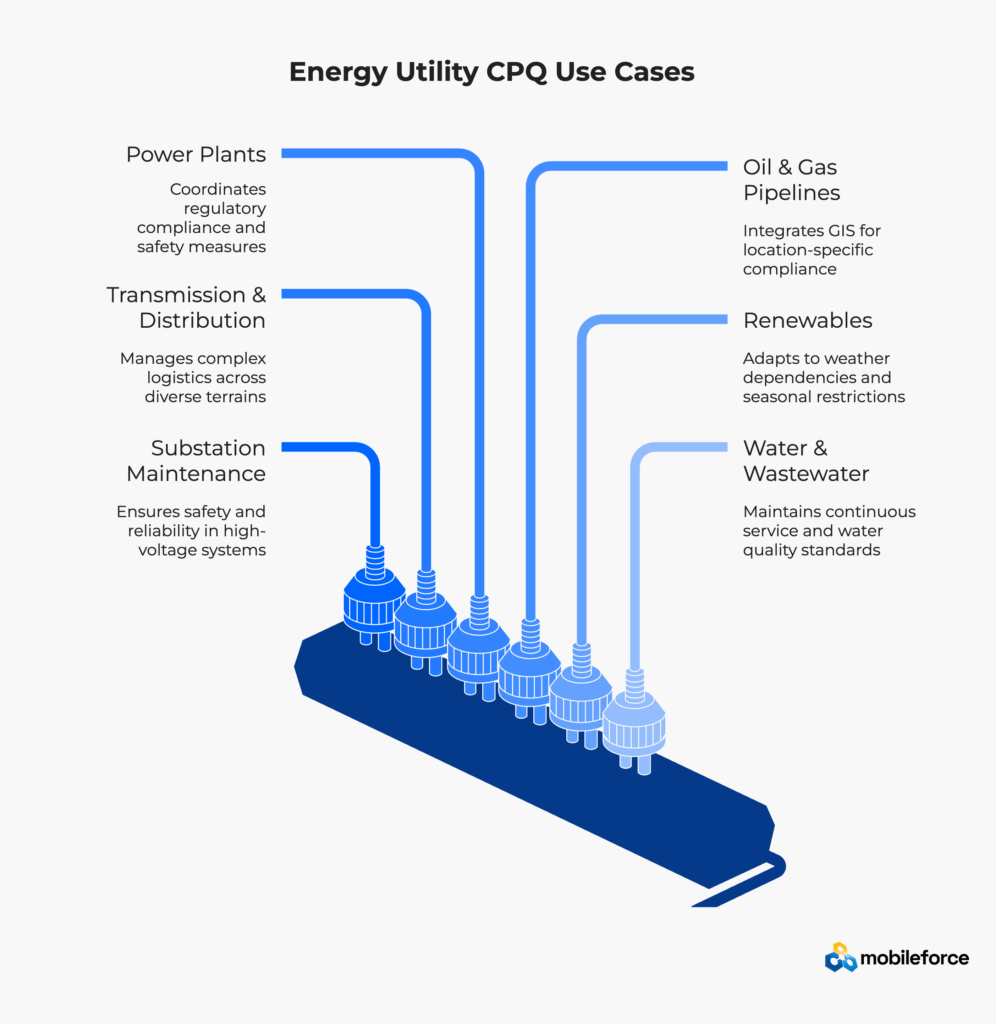

Energy and utilities encompass diverse operational environments, each requiring specialized utility asset management approaches and unique electrical infrastructure service requirements. Understanding how unified energy utility CPQ platforms address specific scenarios helps illustrate the platform’s practical value for power company operations.

Electrical substations require meticulous maintenance procedures that balance safety, reliability, and regulatory compliance for power grid operations. Standardized service bundles ensure that quotes automatically include specialized safety equipment, certified electrical technicians, and environmental protection measures specific to high-voltage electrical system service. Parts validation prevents incompatible components that could compromise power system reliability or create safety hazards.

Configuration rules account for voltage levels (distribution, transmission, extra high voltage), manufacturer specifications, and regional safety standards for electrical infrastructure maintenance. When technicians configure maintenance for high-voltage equipment, the utility operations management system automatically includes appropriate isolation procedures, testing protocols, and restoration checklists.

Substation-Specific Configuration Elements:

Power line maintenance involves complex logistics that span multiple jurisdictions and environmental conditions for electrical infrastructure service. Labor calculations must account for terrain difficulty, weather restrictions, and specialized equipment requirements. Environmental factors influence scheduling, materials selection, and access procedures for power grid maintenance.

Automated quotes include helicopter services for remote line sections, specialized vehicles for difficult terrain, and environmental mitigation measures for sensitive habitats. The energy utility CPQ system coordinates with utility dispatch to ensure power system maintenance occurs during optimal system conditions.

T&D Maintenance Complexity Factors:

Generation facility maintenance requires extensive regulatory and engineering approvals due to the complexity and safety implications of power equipment servicing. Automated documentation ensures compliance with nuclear safety standards, environmental regulations, and performance testing requirements for power generation operations.

Multi-stakeholder approval workflows coordinate safety, engineering, environmental, and regulatory reviews. Emergency bypass procedures enable critical safety repairs while maintaining proper oversight and documentation for electrical infrastructure service.

Power Plant Maintenance Requirements:

Pipeline maintenance involves documentation-heavy inspections and repairs that must satisfy multiple regulatory agencies for energy infrastructure operations. Automated compliance templates ensure proper documentation for environmental impact, safety protocols, and performance monitoring.

Integration with GIS systems enables location-specific requirements based on terrain, population density, and environmental sensitivity. Emergency response procedures automatically include environmental containment measures and community notification protocols.

Wind and solar facilities require specialized maintenance approaches that account for weather dependencies and seasonal access restrictions for power equipment servicing. Preventive maintenance scheduling coordinates with weather forecasting and equipment availability.

Large component replacement, such as wind turbine gearboxes, requires specialized transportation and installation equipment. Quotes automatically include crane services, road permits, and coordination with aviation authorities for installations near flight paths.

Renewable Energy Maintenance Specialization:

Utility systems serving water and wastewater treatment require maintenance that ensures continuous service while maintaining water quality standards. Asset variability across treatment plants demands flexible configuration options that account for different technologies and capacity requirements for utility operations management.

Regional compliance requirements vary significantly based on water source protection, environmental discharge permits, and public health regulations. Automated templates ensure quotes include appropriate testing, monitoring, and reporting requirements for water utility asset management.

|

Infrastructure Type |

Key Challenges |

CPQ Solutions |

Regulatory Requirements |

Typical Project Duration |

|

Electrical Substations |

High-voltage safety, equipment compatibility |

Automated safety bundles, voltage-specific rules |

NERC, OSHA, IEEE standards |

2-8 hours (emergency) to 2-4 weeks (planned) |

|

Transmission Lines |

Weather dependency, environmental compliance |

Helicopter services, terrain-specific equipment |

EPA, Endangered Species Act |

4-12 hours to 6-8 weeks |

|

Power Plants |

Multi-stakeholder approvals, complex testing |

Automated documentation, parallel workflows |

NRC, EPA, FERC oversight |

8-24 hours to 12-16 weeks |

|

Distribution Systems |

Urban coordination, customer impact |

Traffic management, outage coordination |

Local permits, utility commission |

2-6 hours to 1-2 weeks |

|

Renewable Facilities |

Weather windows, specialized equipment |

Predictive scheduling, crane coordination |

FAA, environmental permits |

6-12 hours to 4-6 weeks |

|

Pipeline Infrastructure |

Environmental sensitivity, documentation |

GIS integration, containment protocols |

EPA, PHMSA, state agencies |

4-8 hours to 8-12 weeks |

Transform specialized energy maintenance operations across all facility types. Contact Mobileforce to learn how industry-specific CPQ configurations optimize your power infrastructure maintenance workflows.

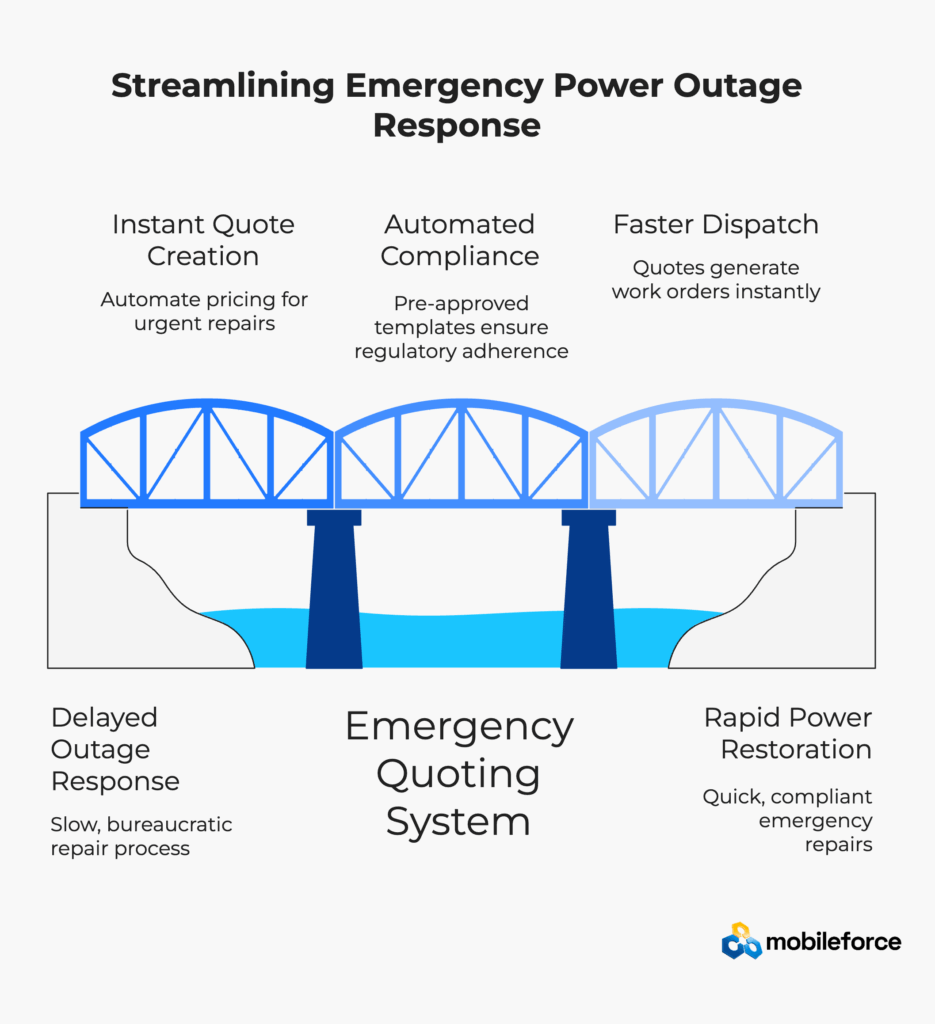

When electrical infrastructure fails unexpectedly, response time often determines the scope of customer impact and potential safety hazards for power companies. Emergency quoting capabilities transform how energy companies respond to critical power outages by eliminating bureaucratic delays while maintaining proper oversight through utility operations management systems.

Instant quote creation for emergency power repairs recognizes the urgency of unplanned electrical outages. The energy utility CPQ system automatically applies surge labor rates for after-hours and weekend work, accounts for expedited shipping costs, and includes emergency equipment rental when regular inventory is insufficient for power grid restoration.

Automated compliance documentation ensures emergency electrical infrastructure repairs maintain proper regulatory oversight even under time pressure. Pre-approved emergency templates include all required safety protocols, environmental protections, and reporting requirements for power system maintenance. This preparation enables rapid deployment while satisfying NERC, OSHA, and EPA regulatory obligations.

Faster dispatch becomes possible when quotes automatically generate work orders with complete material lists, labor assignments, and safety protocols for utility field operations. Field crews can respond immediately to power outages rather than waiting for manual paperwork to catch up with urgent electrical repair needs.

|

Traditional Emergency Response |

Unified Energy Utility CPQ Emergency Response |

|

2-4 hours for emergency power outage quotes |

15-30 minutes for complete electrical repair packages |

|

Manual safety documentation for electrical work |

Automated compliance templates for power infrastructure |

|

Phone-based approvals during power outages |

Mobile emergency authorization for electrical repairs |

|

Separate work order creation for utility crews |

Integrated quote-to-dispatch for power system restoration |

|

Manual vendor coordination for power equipment |

Automated supplier notifications for electrical components |

|

Disconnected inventory management |

Real-time parts availability for power grid repairs |

|

Paper-based emergency protocols |

Digital emergency response workflows |

Service restoration speeds improve when emergency power outage quotes include realistic timelines based on parts availability, crew deployment, and electrical repair complexity. Customers receive accurate restoration estimates rather than vague promises that may not reflect power grid reality.

Emergency Response Performance Metrics: According to IEEE Power & Energy Society standards, optimal emergency response for electrical utilities includes:

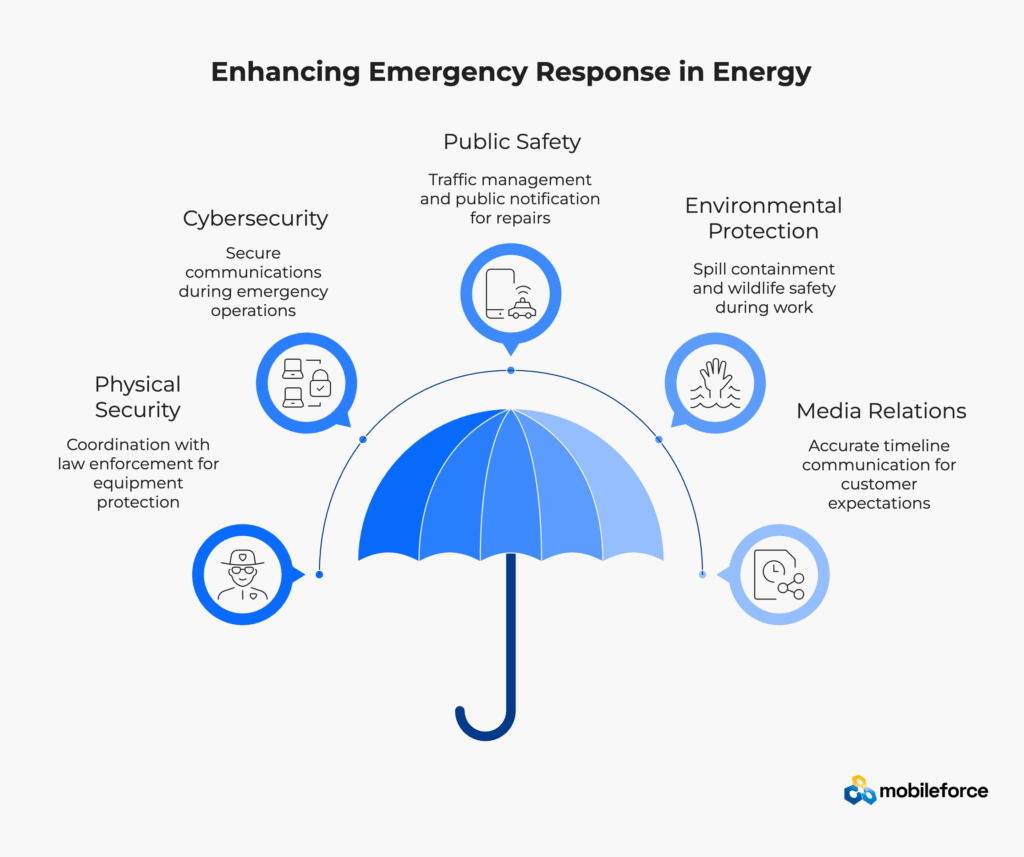

Power companies face increasing scrutiny from federal agencies regarding grid security and emergency preparedness. The Department of Homeland Security’s Cybersecurity and Infrastructure Security Agency (CISA) emphasizes the importance of rapid response capabilities for electrical infrastructure protection.

Emergency power outage quoting must account for:

Ensure your emergency response capabilities meet federal standards for critical infrastructure protection. Contact Mobileforce to learn how unified utility CPQ accelerates critical electrical infrastructure repairs while maintaining regulatory compliance.

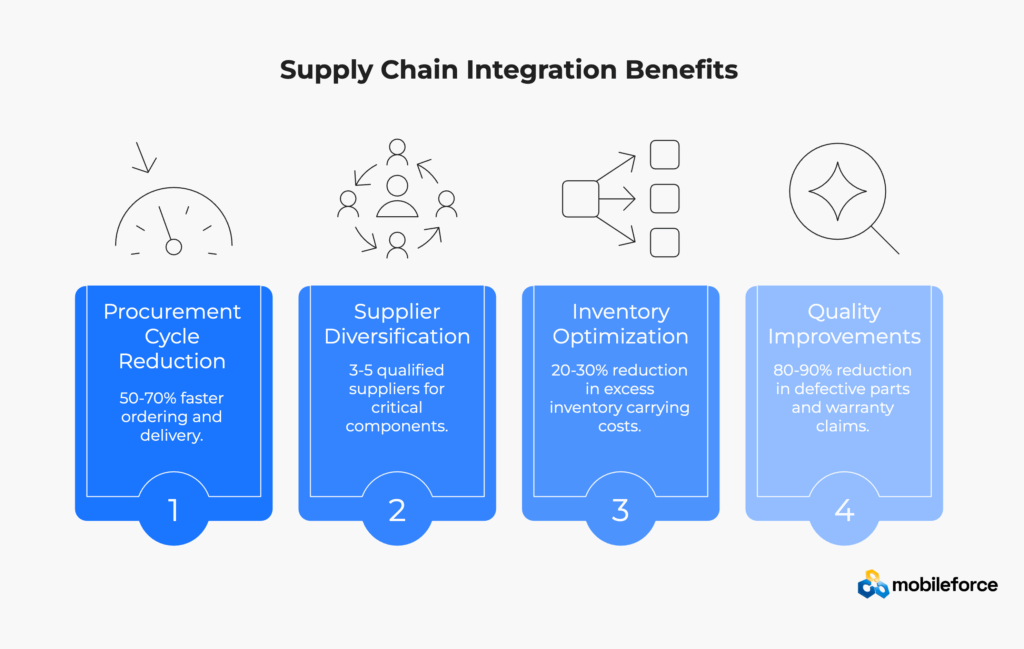

Energy infrastructure maintenance often requires specialized components from multiple suppliers, creating procurement complexity that traditional systems struggle to handle efficiently. According to Boston Consulting Group’s utility supply chain research, power companies typically work with 200-500 different suppliers for MRO components, with critical parts often sourced from 5-15 specialized vendors.

Modern energy utility CPQ platforms address these challenges through real-time vendor integration and intelligent supplier selection. The Institute for Supply Management reports that utilities implementing digital procurement achieve 15-25% cost reductions and 40-60% improvement in procurement cycle times.

Real-time pricing and inventory visibility across multiple suppliers ensures utility field operations crews have access to required components when emergencies occur. The system maintains connections to primary suppliers while providing backup options when preferred vendors experience shortages or capacity constraints. Advanced sales team coordination enables rapid vendor communication and contract negotiation during supply chain disruptions.

Intelligent vendor selection considers factors beyond price, including delivery timing, quality certifications, and previous performance history. For critical safety components, the system prioritizes certified suppliers even when alternatives might offer lower costs. The National Association of Electrical Distributors (NAED) emphasizes that quality certifications can reduce equipment failure rates by 60-80% compared to non-certified alternatives.

Procurement automation reduces manual coordination by automatically generating purchase orders when quotes receive approval. Vendor notifications include delivery requirements, safety protocols, and site-specific access instructions. This coordination reduces delays and ensures suppliers understand project requirements for power infrastructure maintenance.

Supply chain bottlenecks frequently delay maintenance projects in the energy sector, particularly for specialized electrical equipment with limited supplier networks. Recent supply chain challenges have increased procurement complexity, making real-time visibility more critical than ever for utility operations management.

According to the U.S. Chamber of Commerce Supply Chain Research, 78% of utilities report supply chain disruptions affecting critical maintenance schedules. The American Public Power Association notes that utilities with diversified supplier networks reduce procurement delays by 45-55% compared to single-source strategies.

Predictive inventory management helps prevent stockouts of critical components by analyzing usage patterns, equipment lifecycle stages, and seasonal maintenance demands. The system recommends optimal stocking levels for high-value spare parts while minimizing carrying costs for slower-moving inventory. Modern revenue operations optimization includes sophisticated demand forecasting that accounts for historical usage patterns and predictive maintenance schedules.

Emergency procurement protocols provide alternative sourcing strategies when primary suppliers cannot meet urgent delivery requirements. Pre-negotiated agreements with backup suppliers enable rapid sourcing without compromising quality or safety standards for electrical infrastructure service.

Quality assurance integration ensures procured components meet specification requirements and regulatory standards. Digital certificates, test reports, and compliance documentation automatically attach to procurement records, simplifying regulatory audits and maintenance tracking. The International Association of Electrical Inspectors requires documented quality assurance for all electrical components used in power infrastructure projects.

Supply Chain Performance Metrics: According to Accenture’s Utility Supply Chain Excellence study, leading utilities achieve:

Optimize your utility procurement operations today. Explore Mobileforce’s integrated supply chain management capabilities designed for power company operations.

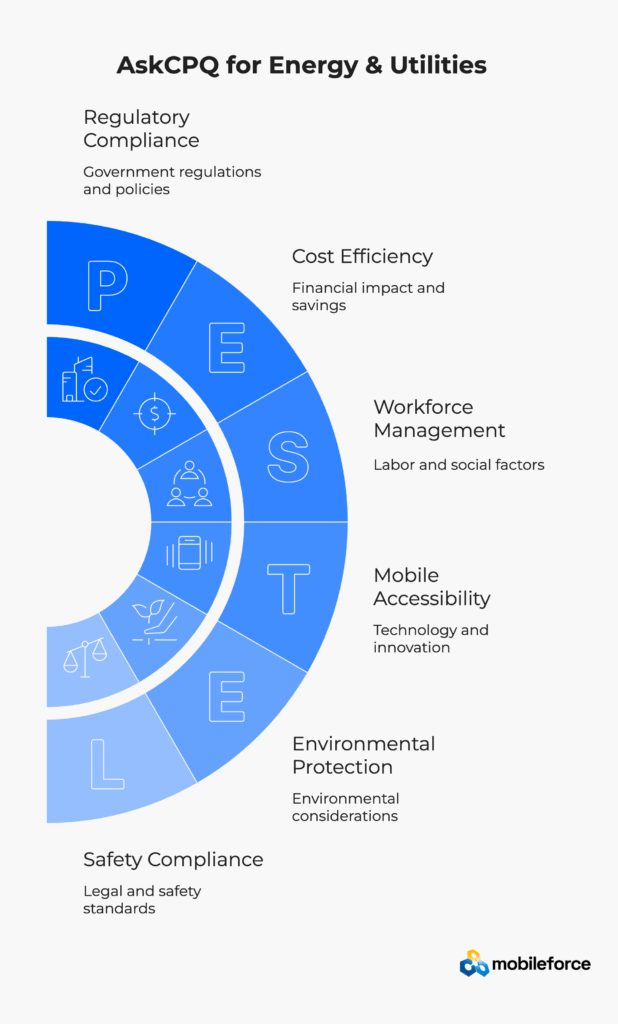

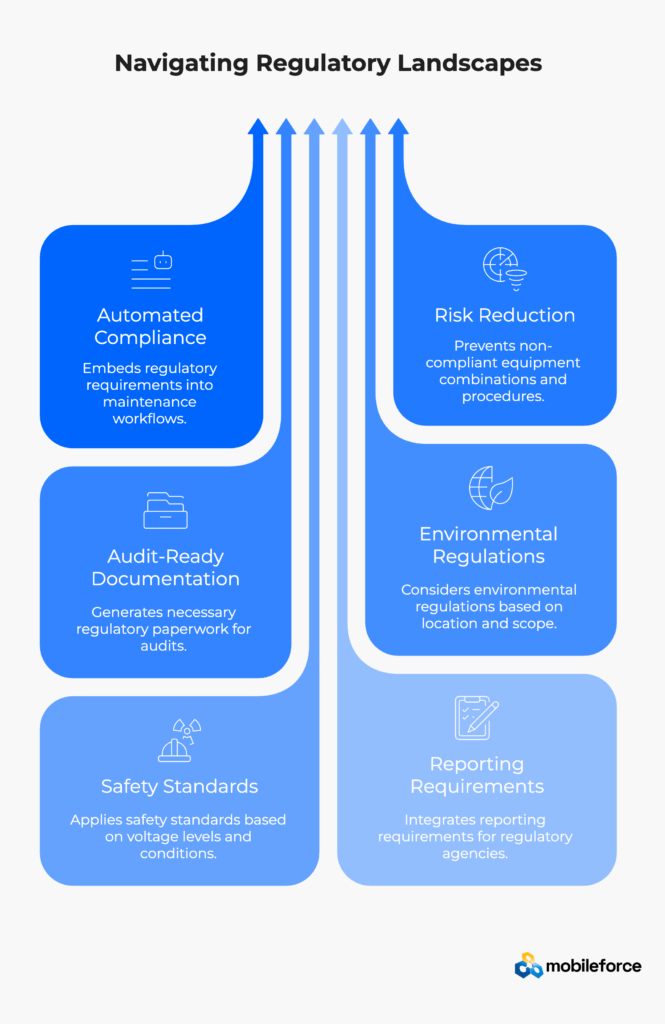

Energy and utilities operate under complex regulatory frameworks that vary by jurisdiction, equipment type, and environmental conditions. According to the American Bar Association’s Energy Law guide, utilities face oversight from an average of 15-20 different federal, state, and local agencies. Compliance failures can result in significant fines, safety violations, and operational restrictions that far exceed the cost of proper maintenance procedures.

The Government Accountability Office reports that utility regulatory violations have increased 35% over the past decade, with average fines ranging from $100,000 to $50 million depending on severity. The Federal Energy Regulatory Commission levied over $25 million in civil penalties in 2023 for compliance violations related to grid reliability and safety standards.

Automated compliance application eliminates manual research by embedding regulatory requirements directly into quoting workflows. When technicians configure maintenance for specific electrical equipment types in particular locations, the energy utility CPQ system automatically applies relevant safety standards, environmental protections, and reporting requirements. Advanced document creation capabilities ensure all compliance documentation meets federal and state requirements.

Risk reduction strategies include configuration validation that prevents non-compliant equipment combinations or maintenance procedures. If a proposed repair would violate safety standards or environmental regulations, the system flags the issue and suggests compliant alternatives. The National Institute for Occupational Safety and Health (NIOSH) reports that automated safety validation reduces electrical worker injuries by 40-50%.

Audit-ready documentation generation ensures maintenance quotes include all necessary regulatory paperwork from the initial planning stage. This preparation reduces compliance overhead while providing clear audit trails for regulatory reviews. Modern contract lifecycle management integrates compliance tracking throughout vendor relationships and service agreements.

Environmental regulations receive automatic consideration based on equipment location and maintenance scope. The Environmental Protection Agency’s Clean Air Act requirements apply to power generation facilities, while the Clean Water Act governs discharge permits for water-cooled power plants. Work near sensitive habitats automatically includes wildlife protection measures per the Endangered Species Act, while maintenance in urban areas accounts for noise restrictions and emissions controls.

Safety standards application varies based on voltage levels, hazardous materials, and working conditions. The Occupational Safety and Health Administration mandates specific procedures for electrical work above 50 volts, with enhanced requirements for transmission-level equipment. High-voltage maintenance automatically includes appropriate isolation procedures, while confined space work includes required safety equipment and monitoring protocols per OSHA’s Confined Space Standard.

Reporting requirements integration ensures maintenance activities include proper documentation for regulatory agencies. The North American Electric Reliability Corporation requires specific incident reporting and equipment performance documentation. Automated templates capture required data points while standardizing format and content across different maintenance scenarios.

Quality assurance protocols ensure maintenance procedures meet industry standards and manufacturer specifications. Documentation packages include test results, certification records, and performance verification that satisfy both regulatory and warranty requirements. The International Electrotechnical Commission (IEC) establishes global standards for electrical equipment testing and certification that utilities must follow for international equipment purchases.

Regulatory Compliance Statistics: According to Ernst & Young’s Utility Regulatory Trends report:

The National Association of Regulatory Utility Commissioners emphasizes that proactive compliance management through automated systems reduces regulatory risk while improving operational efficiency.

|

Regulatory Category |

Governing Agency |

Key Requirements |

Typical Penalties |

CPQ Automation Benefits |

|

Electrical Safety |

OSHA, IEEE |

Personal protective equipment, isolation procedures |

$100K-$500K per violation |

Automated safety bundle validation |

|

Grid Reliability |

NERC, FERC |

CIP compliance, outage reporting |

$1M-$50M per violation |

Real-time incident documentation |

|

Environmental |

EPA, State Agencies |

Emissions monitoring, waste management |

$500K-$10M per violation |

Automated environmental impact assessment |

|

Nuclear Safety |

NRC |

Radiation protection, containment protocols |

$10M-$100M per violation |

Comprehensive safety procedure automation |

|

Pipeline Safety |

PHMSA, DOT |

Integrity management, leak detection |

$2M-$25M per violation |

GIS-integrated compliance tracking |

|

Water Quality |

EPA, State Agencies |

Discharge permits, monitoring requirements |

$50K-$5M per violation |

Automated water quality documentation |

|

Cybersecurity |

CISA, NERC |

Critical infrastructure protection |

$1M-$10M per violation |

Secure digital workflow management |

|

Emergency Response |

FEMA, DHS |

Response plan documentation, coordination |

$100K-$2M per violation |

Automated emergency procedure templates |

Ensure comprehensive regulatory compliance across all utility operations. Learn how Mobileforce CPQ automates compliance documentation and reduces regulatory risk for power companies.

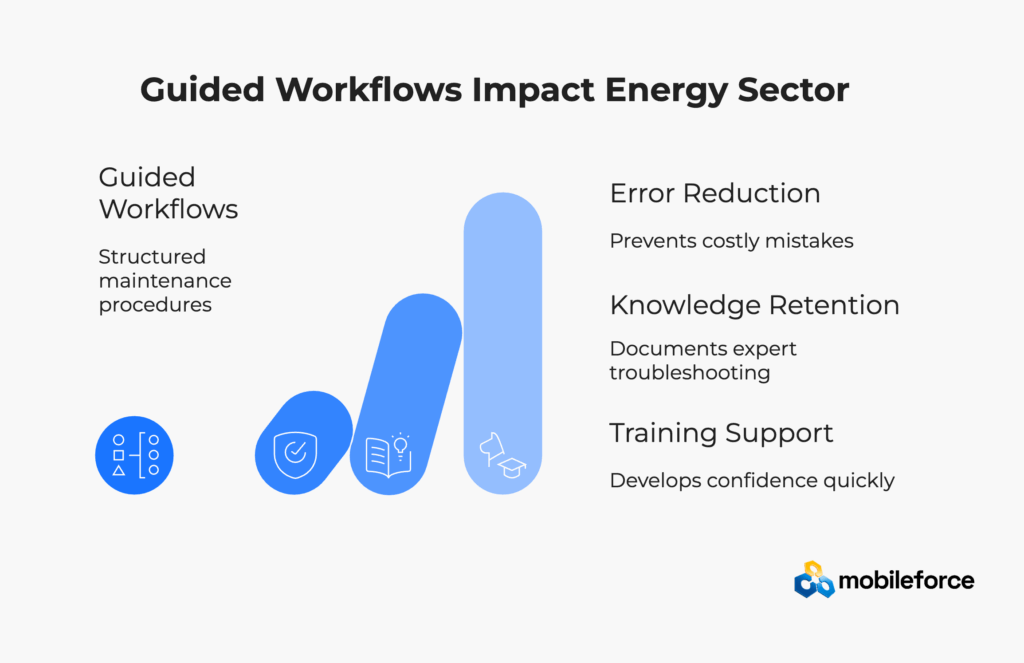

The energy sector faces significant workforce challenges as experienced professionals retire while recruiting and training new talent becomes increasingly difficult. The skilled labor shortage affects MRO operations across the industry, making knowledge retention and transfer critical for operational continuity.

Guided workflows help junior technicians navigate complex maintenance procedures by codifying expert knowledge into structured processes. Instead of relying on informal mentorship or trial-and-error learning, new employees can follow proven procedures that incorporate safety protocols, regulatory requirements, and best practices.

Error reduction through systematic guidance prevents costly mistakes that occur when inexperienced technicians attempt complex maintenance without adequate support. The system provides step-by-step instructions, safety checkpoints, and verification procedures that reduce the likelihood of equipment damage or safety incidents.

Knowledge capture enables experienced professionals to document their expertise in formats that remain accessible after retirement. Senior technicians can create custom workflows, document troubleshooting procedures, and establish standards that preserve institutional knowledge for future use.

Consistent procedures across different maintenance scenarios help new employees develop confidence and competence more quickly. Standardized approaches reduce confusion while ensuring safety standards remain consistent regardless of individual experience levels.

Performance tracking enables supervisors to identify training needs and provide targeted development opportunities. The system captures decision patterns, identifies areas where additional guidance might be helpful, and tracks improvement over time.

Mentorship integration allows experienced professionals to provide remote guidance and support. Digital workflows can include consultation points where senior technicians review decisions and provide feedback without requiring physical presence at job sites.

Address workforce challenges with systematic knowledge retention. Explore Mobileforce’s guided workflow capabilities designed to support skills transfer and operational continuity.

Consider a mid-sized regional electric utility serving 500,000 customers across a diverse service territory that includes urban centers, rural communities, and industrial facilities. The utility operates 45 electrical substations, 3,200 miles of transmission lines, and maintains relationships with 12 major suppliers for electrical infrastructure MRO components. This hypothetical scenario illustrates common challenges faced by power companies implementing energy utility CPQ platforms.

Prior to implementing unified energy utility CPQ software, the utility struggled with fragmented power company quoting processes that delayed critical electrical infrastructure maintenance projects. Field supervisors used paper forms for routine work orders while emergency power outage repairs required phone coordination between multiple departments. Approval processes averaged 3-5 days for standard electrical maintenance and often extended longer for complex projects requiring environmental reviews for power grid operations.

Supply chain coordination created additional delays when multiple vendors were required for single electrical infrastructure projects. Procurement teams spent significant time coordinating delivery schedules, ensuring specification compliance for power equipment, and managing vendor communications. Emergency power outage repairs often proceeded with verbal approvals followed by extensive paperwork reconciliation for utility operations management.

Compliance documentation consumed substantial administrative resources as electrical technicians manually prepared regulatory reports, safety documentation, and audit trails for power system maintenance. Quality inconsistencies occurred when different teams followed varied procedures or overlooked regulatory requirements under time pressure during electrical infrastructure service.

Pre-Implementation Performance Metrics:

The utility deployed Mobileforce enterprise CPQ solution with integrated AskCPQ capabilities, connecting the platform to existing CRM, ERP, and FSM systems for utility asset management. Implementation included custom configuration rules for electrical substation maintenance, transmission line repairs, and emergency power outage response procedures.

Conversational quoting enabled utility field operations technicians to generate accurate quotes using mobile devices and natural language requests. Custom prompts captured recurring electrical infrastructure maintenance scenarios while automated workflows routed approvals based on cost thresholds, safety requirements, and regulatory considerations for power company operations.

Multi-vendor integration provided real-time visibility into electrical supplier inventory and pricing while automated procurement generated purchase orders immediately upon quote approval. Emergency response templates enabled rapid deployment while maintaining compliance documentation for power grid restoration.

Implementation Timeline:

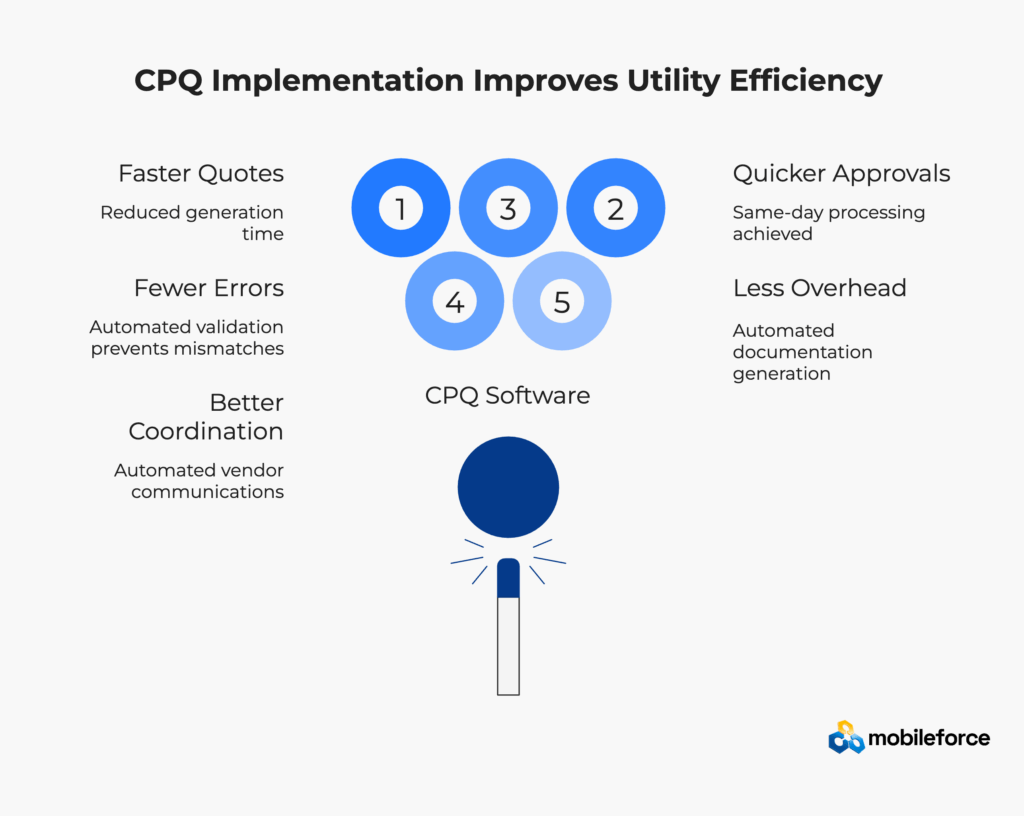

Quote generation time decreased from 2.5 hours to 25 minutes for standard electrical infrastructure maintenance projects, with emergency power outage repairs receiving complete quote packages within 45 minutes. Approval cycles shortened from 3-5 days to same-day processing for routine electrical work and 24-hour turnaround for complex projects requiring multiple stakeholders in utility operations management.

Error reduction improved significantly as automated validation prevented specification mismatches and compliance oversights for power equipment maintenance. Field crews reported higher confidence in work packages due to complete material lists and clear procedure documentation for electrical infrastructure service.

Compliance overhead decreased by approximately 60% as automated templates generated required documentation during the quoting process rather than after project completion. Regulatory audits became more efficient due to consistent documentation standards and complete audit trails for power system maintenance.

Supply chain coordination improved through automated vendor communications and delivery tracking for electrical equipment. Emergency parts procurement accelerated through pre-negotiated supplier agreements and automated escalation procedures for power outage restoration.

Post-Implementation Performance Improvements:

Financial Impact Analysis: According to utility industry benchmarks, the utility achieved:

Transform your utility’s electrical infrastructure MRO operations with proven energy CPQ solutions. Schedule a discussion about implementing unified quoting and work-order management for your power company operations.

Understanding the technical architecture of unified energy utility CPQ and work-order management helps power companies evaluate implementation requirements and integration possibilities. According to Gartner’s Utility Technology Architecture research, modern platforms must accommodate diverse data sources, varying user interfaces, and complex approval workflows while maintaining system reliability and security for critical electrical infrastructure operations.

The core rules engine processes configuration logic specific to energy infrastructure maintenance. According to IEEE Computer Society standards, enterprise-grade CPQ platforms must handle 10,000+ configuration rules while maintaining sub-second response times. Rule sets accommodate electrical equipment specifications, safety protocols, regulatory requirements, and vendor qualifications for power system maintenance.

Hierarchical rule structures enable different levels of validation based on equipment criticality, maintenance complexity, and safety implications. Simple component replacements might require basic validation while major overhauls trigger comprehensive safety and regulatory reviews. The International Society of Automation emphasizes that rule-based validation prevents 85-95% of configuration errors that could compromise safety or compliance.

Advanced manufacturing-grade rule engines support complex electrical equipment configurations with multiple dependency chains and constraint checking. Machine learning algorithms continuously optimize rule performance based on historical maintenance patterns and outcomes.

The AI layer processes natural language requests and translates them into structured configuration parameters for utility operations management. According to MIT Technology Review’s AI research, conversational AI platforms achieve 90-95% accuracy in domain-specific applications when properly trained on industry terminology.

Machine learning algorithms continuously improve understanding of electrical industry terminology, common maintenance scenarios, and user preferences. Integration APIs connect the conversational interface to underlying data sources, ensuring AI recommendations reflect current equipment status, inventory availability, and regulatory requirements. This connection enables contextually appropriate responses that account for real-world constraints in power infrastructure operations.

Natural language processing capabilities understand context-specific requests like “emergency transformer maintenance at Substation 12” and automatically translate them into proper equipment codes, safety requirements, and regulatory compliance needs.

API-level integrations provide bidirectional data flow between energy utility CPQ and existing enterprise systems. According to Forrester’s Enterprise Architecture research, successful utility digital transformations require integration with an average of 15-20 different operational systems.

Customer relationship management systems supply account information and service history while field service management platforms provide asset databases and work order templates. Enterprise resource planning integration ensures financial accuracy and procurement automation through revenue operations coordination.

Real-time data synchronization capabilities handle high-volume transactions typical in utility operations, with enterprise-grade platforms supporting 1,000+ concurrent users and 100,000+ daily transactions. Modern API architectures use RESTful services and event-driven messaging to ensure data consistency across integrated systems.

Real-time synchronization ensures quotes seamlessly convert to work orders with complete material lists, labor assignments, and procedural documentation for electrical infrastructure service. Updates flow bidirectionally, allowing field changes to update quotes and quotes modifications to refresh work orders automatically.

Mobile optimization enables utility field operations technicians to access complete work packages through mobile devices while maintaining offline capabilities for areas with limited connectivity. Synchronization occurs automatically when network access resumes, preventing data loss during field work.

According to the Mobile Enterprise Alliance, field-optimized applications reduce data entry time by 60-80% compared to desktop-based systems while improving accuracy through automated data validation.

Automated documentation generation produces regulatory reports, safety protocols, and audit trails that satisfy industry standards for power infrastructure maintenance. Templates accommodate different regulatory frameworks including NERC, FERC, EPA, and OSHA requirements while ensuring consistent quality and completeness.

Digital signature capabilities enable remote approvals and electronic record keeping that meets legal requirements for utility contracts and regulatory filings. Advanced document creation capabilities automatically generate compliance packages that include all required certifications, test results, and performance verification.

Audit trails capture all system interactions for compliance verification and performance analysis, with enterprise-grade platforms maintaining 7-10 year historical records as required by utility regulatory frameworks. Blockchain-based audit trails provide tamper-proof documentation for critical safety and environmental compliance records.

|

System Component |

Core Functions |

Integration Capabilities |

Performance Requirements |

Compliance Features |

|

CPQ Rules Engine |

Configuration validation, pricing logic, safety protocols |

ERP, CRM, FSM, regulatory databases |

10,000+ rules, <1 second response |

NERC, OSHA, IEEE standards |

|

AskCPQ AI Layer |

Natural language processing, conversational interfaces |

Voice-to-text, mobile apps, CRM data |

90-95% accuracy, multi-language |

Secure data processing |

|

Work-Order Integration |

Quote-to-work conversion, field change orders |

FSM platforms, mobile devices |

Real-time sync, offline capability |

Digital audit trails |

|

Vendor Management |

Multi-supplier procurement, inventory tracking |

Supplier portals, ERP systems |

Real-time pricing, 24/7 availability |

Quality certifications |

|

Compliance Engine |

Regulatory templates, documentation automation |

Agency databases, reporting systems |

Automated compliance checking |

Multi-agency requirements |

|

Mobile Platform |

Field access, offline capability, photo capture |

Smartphones, tablets, rugged devices |

Cross-platform compatibility |

Encrypted data transmission |

|

Analytics Dashboard |

Performance metrics, trend analysis, reporting |

BI tools, executive dashboards |

Real-time data visualization |

Role-based access control |

|

Security Framework |

Multi-factor authentication, encryption, audit logs |

Identity management, SIEM systems |

99.9% uptime, SOC 2 compliance |

NIST cybersecurity framework |

Technical Architecture Requirements: According to NIST Cybersecurity Framework guidelines for critical infrastructure:

Explore technical architecture options for your utility operations. Schedule a technical consultation to discuss integration requirements and system specifications for your power company infrastructure.

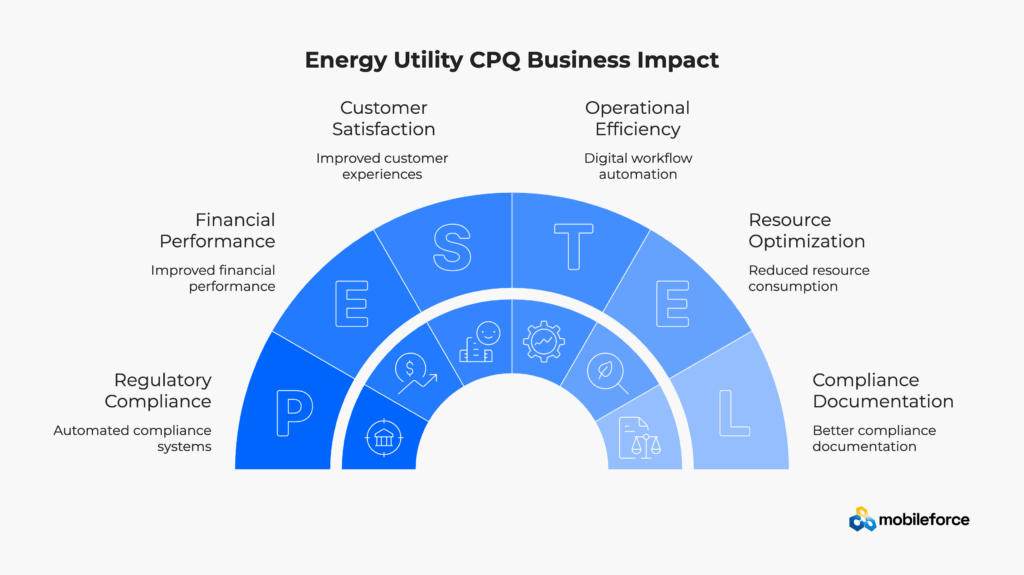

The convergence of modern CPQ capabilities with energy sector requirements creates measurable business value across multiple operational dimensions. According to McKinsey & Company’s Utility Digital Transformation study, organizations implementing unified quoting and work-order management typically experience improvements in efficiency, accuracy, compliance, and customer satisfaction.

Faster quote creation and approval processes reduce administrative overhead while accelerating project timelines for power infrastructure maintenance. Field technicians spend more time on value-adding maintenance activities rather than paperwork coordination. Supervisors gain bandwidth for strategic planning and performance optimization rather than manual process management for utility operations.

According to Deloitte’s Utility Operations Excellence research, utilities implementing digital workflow automation achieve:

Reduced errors minimize rework, warranty claims, and safety incidents that consume substantial resources. Automated validation prevents specification mismatches that could require equipment replacement or safety retrofits. Consistent procedures reduce variability that leads to quality issues and customer complaints for electrical infrastructure service.

Better compliance documentation reduces regulatory overhead and audit preparation time. Automated templates ensure consistent quality while eliminating manual research and document preparation. Digital audit trails provide immediate access to historical records during regulatory reviews. The American Public Power Association reports that utilities with automated compliance systems reduce audit preparation time by 60-80%.

Improved throughput enables power companies to complete more maintenance projects with existing resources. Reduced cycle times increase equipment availability while minimizing service disruptions that affect customer satisfaction and revenue generation. Edison Electric Institute research shows that operational efficiency improvements directly correlate with improved financial performance and rate case outcomes.

Procurement optimization through multi-vendor integration and automated supplier selection reduces material costs while improving delivery reliability. Emergency procurement capabilities minimize expediting charges and reduce downtime costs that often exceed material savings. According to Accenture’s Utility Procurement Excellence study, leading utilities achieve 15-25% procurement cost reductions through digital automation.

Enhanced accuracy in project scoping and pricing improves profitability by reducing unexpected costs and change orders. Better visibility into project requirements enables more accurate budgeting and resource allocation across maintenance programs. The Electric Power Research Institute reports that improved project planning accuracy reduces cost overruns by 40-60%.

Financial Impact Metrics: According to PwC’s Digital Utility Finance study:

Stronger coordination between utility field operations, sales, and operations teams improves customer experiences and relationship quality. Faster response times and more accurate project timelines enhance customer confidence while reducing complaints and regulatory scrutiny. Modern sales team effectiveness drives improved customer satisfaction and retention rates.

Operational excellence in maintenance management creates competitive differentiation in regulated markets where service quality affects rate proceedings and franchise agreements. Demonstrated efficiency and reliability support favorable regulatory treatment and customer retention. The National Association of Regulatory Utility Commissioners emphasizes that operational performance directly influences regulatory decisions on rate recovery and service territory expansion.

Knowledge retention and workforce development capabilities address industry-wide talent challenges while building sustainable operational capabilities. Systematic approaches to skills transfer and performance improvement create long-term competitive advantages in utility workforce management. According to Bureau of Labor Statistics projections, 25-30% of electrical utility workers will retire within the next decade, making knowledge retention critical.

Strategic Performance Indicators: Research by Boston Consulting Group shows that digitally advanced utilities achieve:

|

Impact Category |

Specific Metric |

Improvement Range |

Timeframe |

Financial Impact |

Data Source |

|

Operational Efficiency |

Quote generation speed |

85-90% faster |

3-6 months |

$500K-$2M annual savings |

Deloitte/McKinsey |

|

Cost Reduction |

Overall maintenance expenses |

12-20% decrease |

6-12 months |

$1M-$5M annual savings |

PwC |

|

Emergency Response |

Outage restoration time |

35-50% faster |

Immediate |

$2M-$10M annual savings |

EPRI/DOE |

|

Procurement Optimization |

Material costs |

15-25% reduction |

3-9 months |

$800K-$3M annual savings |

Accenture |

|

Compliance Management |

Regulatory violations |

60-75% reduction |

6-18 months |

$2M-$15M risk mitigation |

GAO/NARUC |

|

Workforce Productivity |

Administrative overhead |

45-60% reduction |

3-12 months |

$1.5M-$4M annual savings |

Deloitte |

|

Customer Satisfaction |

Service rating improvement |

15-25% increase |

6-18 months |

Revenue protection $5M-$20M |

EEI/BCG |

|

Inventory Management |

Carrying cost reduction |

20-30% decrease |

6-12 months |

$500K-$2.5M annual savings |

Accenture |

|

Quality Improvements |

Defective parts reduction |

80-90% decrease |

3-9 months |

$300K-$1.5M annual savings |

IAEI |

|

Project Accuracy |

Cost overrun reduction |

40-60% decrease |

6-18 months |

$2M-$8M annual savings |

EPRI |

|

ROI Milestone |

3 Months |

6 Months |

12 Months |

24 Months |

36 Months |

|

Investment Recovery |

15-25% |

45-65% |

100-150% |

200-300% |

300-450% |

|

Annual Savings |

$800K-$1.5M |

$2M-$4M |

$4M-$8M |

$6M-$12M |

$8M-$15M |

|

Efficiency Gains |

25-35% |

45-60% |

70-85% |

85-95% |

90-98% |

|

User Adoption |

60-75% |

85-95% |

95-99% |

98-100% |

99-100% |

|

Process Automation |

40-55% |

70-85% |

85-95% |

90-98% |

95-99% |

Measure the business impact of unified CPQ for your energy operations. Request a consultation to discuss specific performance improvements and implementation strategies for your power company operations.

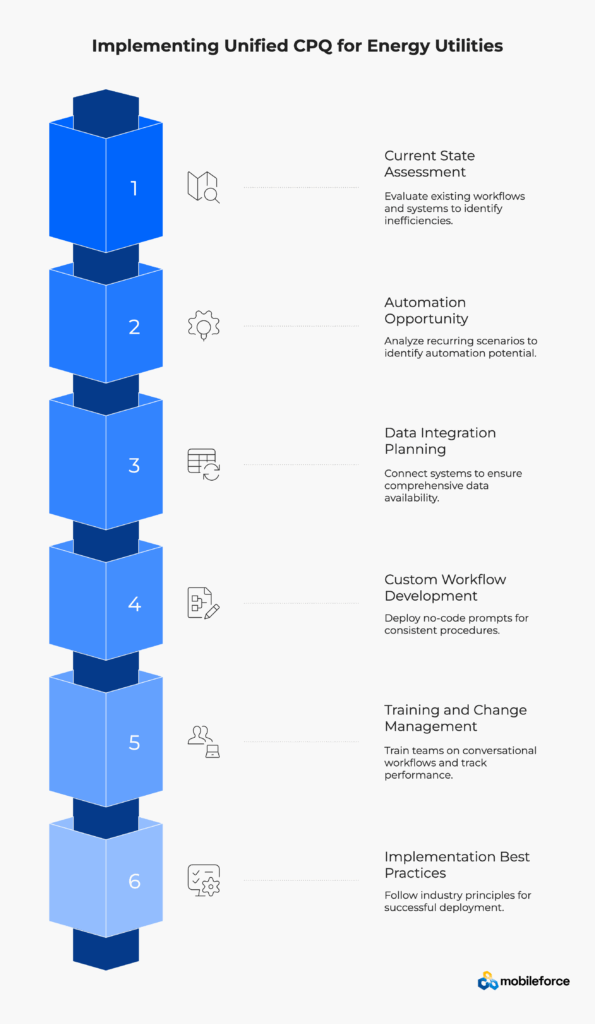

Implementing unified energy utility CPQ and work-order management for power company operations requires systematic planning that accounts for existing systems, organizational workflows, and regulatory requirements. Success depends on thorough preparation, stakeholder alignment, and phased deployment that minimizes operational disruption for electrical infrastructure service.

Begin by mapping existing utility quoting-to-work-order workflows to identify bottlenecks, inefficiencies, and integration points for power system maintenance. Document how different departments currently coordinate electrical infrastructure maintenance projects, including approval processes, vendor management, and compliance documentation. This baseline assessment provides the foundation for improvement planning and success measurement in utility operations management.

Evaluate current system capabilities and limitations across ERP, CRM, FSM, and other operational platforms for power company operations. Identify data sources that must integrate with energy utility CPQ while assessing data quality and accessibility. Understanding existing technical architecture informs integration planning and resource requirements for electrical infrastructure service management.

Assessment Checklist for Power Companies:

Analyze recurring electrical infrastructure maintenance scenarios to identify optimal opportunities for AskCPQ implementation in utility field operations. Focus on high-frequency activities where conversational interfaces could significantly reduce complexity or improve accuracy for power equipment servicing. Emergency power outage response procedures often provide immediate value due to time pressures and complexity.

Prioritize automation based on business impact, implementation complexity, and stakeholder readiness for power company operations. Start with processes that offer clear value propositions and limited integration requirements before advancing to more complex electrical system service scenarios.

High-Value Automation Targets:

Connect CRM, ERP, FSM, and parts management systems to ensure comprehensive data availability for intelligent utility asset management decisions. Plan data mapping and validation procedures that maintain accuracy while accommodating different data formats and update frequencies for power infrastructure operations.

Establish master data governance procedures that ensure consistent electrical equipment specifications, vendor information, and regulatory requirements across integrated systems. Clean data entry procedures minimize errors while standardized formats improve system performance for energy utility software.

Critical Integration Requirements:

Deploy no-code prompts for recurring utility field operations and service scenarios that capture organizational knowledge and ensure consistent procedures for electrical infrastructure service. Engage experienced electrical technicians in workflow design to incorporate practical insights and safety considerations.

Design approval workflows that balance efficiency with oversight requirements for power company operations. Configure automated routing that recognizes different approval triggers while maintaining flexibility for unusual situations that require manual intervention in utility operations management.

Workflow Development Priorities:

Train utility workforce management teams on conversational workflows that emphasize practical benefits rather than technical features. Provide hands-on experience with real electrical infrastructure scenarios that demonstrate value and build confidence. Support gradual adoption that allows teams to develop proficiency before expanding usage across power system maintenance operations.

Establish performance metrics that track efficiency improvements, error reduction, and user satisfaction for energy utility CPQ implementation. Regular feedback collection helps identify additional automation opportunities while addressing implementation challenges for electrical infrastructure service.

Success Metrics for Power Companies:

According to utility industry implementation studies, successful energy utility CPQ deployments follow these principles:

Phase 1: Foundation (Months 1-2)

Phase 2: Core Deployment (Months 3-4)

Phase 3: Advanced Features (Months 5-6)

Phase 4: Optimization (Ongoing)

|

Implementation Phase |

Duration |

Key Activities |

Resource Requirements |

Expected ROI Milestones |

|

Phase 1: Foundation |

Months 1-2 |

Stakeholder alignment, gap analysis, architecture planning |

Project manager + 2-3 technical leads |

Baseline metrics established |

|

Phase 2: Core Deployment |

Months 3-4 |

Basic CPQ configuration, emergency templates, core integrations |

4-6 developers + 2-3 business analysts |

25% improvement in quote speed |

|

Phase 3: Advanced Features |

Months 5-6 |

AskCPQ customization, multi-vendor integration, full training |

Full implementation team + user trainers |

50% improvement in efficiency |

|

Phase 4: Optimization |

Ongoing |

Performance monitoring, continuous improvement, advanced automation |

1-2 system administrators + business users |

200-400% ROI within 12-24 months |

|

Success Metric |

3 Months |

6 Months |

12 Months |

24 Months |

Industry Standard |

|

Quote Generation Speed |

40% faster |

70% faster |

85% faster |

90% faster |

75-85% improvement |

|

User Adoption Rate |

60% |

85% |

95% |

98% |

90%+ target |

|

Error Reduction |

30% fewer |

60% fewer |

80% fewer |

90% fewer |

75-85% improvement |

|

Cost Savings |

10% |

20% |

35% |

45% |

25-40% target |

|

Customer Satisfaction |

15% improvement |

25% improvement |

35% improvement |

45% improvement |

20-30% target |

Start your energy utility CPQ implementation journey today. Schedule a planning consultation to develop a customized deployment strategy that maximizes operational improvements while minimizing disruption to your power infrastructure maintenance operations.

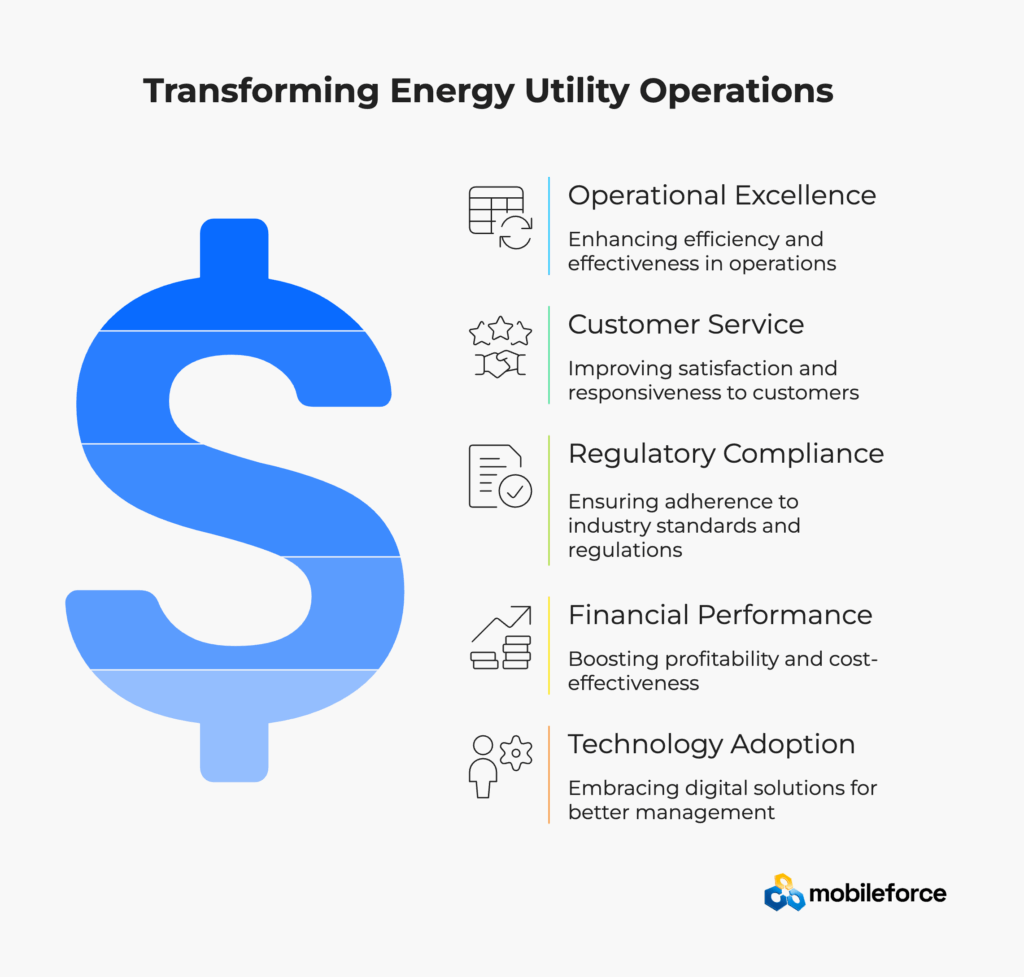

The energy and utilities sector stands at a pivotal transformation point where operational excellence in electrical infrastructure maintenance directly impacts customer service, regulatory compliance, and financial performance for power companies. Traditional approaches to utility MRO quoting and work-order management create inefficiencies that compound across thousands of power system maintenance projects annually, affecting everything from routine electrical equipment servicing to emergency power outage restoration.

Unified energy utility CPQ platforms and work-order management transform these challenges into competitive advantages through intelligent automation, seamless integration, and user-friendly interfaces designed specifically for utility field operations environments. AskCPQ makes sophisticated power company quoting capabilities accessible through conversational interfaces that eliminate training barriers while ensuring accuracy and compliance for electrical infrastructure service operations.

The Vibe Quoting platform recognizes that energy utilities MRO quoting doesn’t have to be tedious or error-prone for utility operations management. Modern interfaces and intelligent automation create user experiences that electrical infrastructure service teams embrace rather than endure. This cultural shift toward technology adoption accelerates implementation benefits while building sustainable operational improvements for power grid maintenance.

As the energy industry continues evolving toward digital transformation and smart grid technologies, power companies that embrace unified utility asset management and work-order management will establish lasting competitive advantages. The combination of operational efficiency, regulatory compliance, and improved customer service creates value that extends far beyond individual electrical maintenance projects to encompass overall power system reliability.

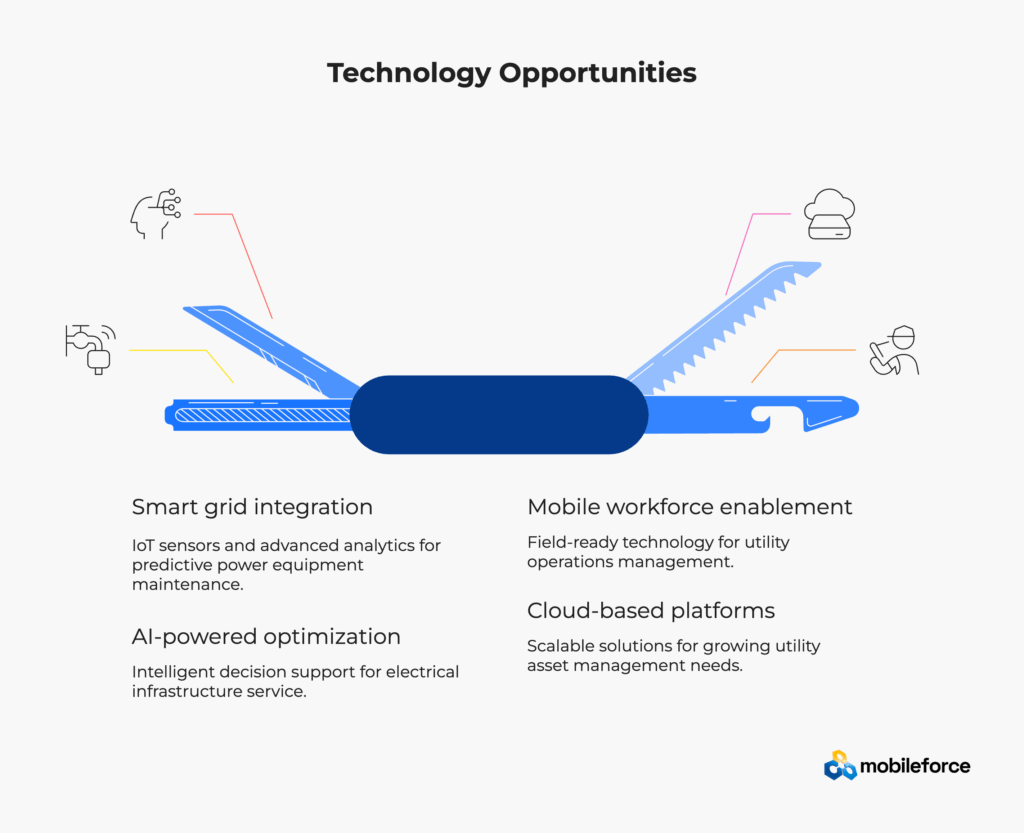

According to the Department of Energy’s Grid Modernization Initiative, utilities must adapt to increasing operational complexity while maintaining reliability standards. Key drivers include:

Infrastructure Challenges:

Regulatory Evolution:

Technology Opportunities:

The future of energy and utilities MRO belongs to power companies that can seamlessly coordinate complex electrical infrastructure maintenance requirements while maintaining safety, compliance, and customer satisfaction. Unified energy utility CPQ platforms provide the foundation for this transformation, turning maintenance management from a cost center into a strategic capability that supports grid modernization and customer service excellence.

Organizations implementing comprehensive utility CPQ platforms report measurable improvements across all operational dimensions: faster emergency response times for power outages, improved regulatory compliance for electrical infrastructure, enhanced technician productivity, and higher customer satisfaction ratings. These benefits create compounding value that strengthens competitive position in both regulated and competitive energy markets.

Modern energy utility software platforms enable power companies to:

The convergence of aging infrastructure, evolving regulations, and advancing technology creates both challenges and opportunities for power companies. Those that invest in unified utility asset management platforms position themselves to thrive in an increasingly complex operating environment while delivering superior value to customers and stakeholders.

Ready to revolutionize your energy and utilities MRO operations? Contact Mobileforce today to discover how unified power company CPQ and work-order management can transform your electrical infrastructure maintenance efficiency, regulatory compliance, and customer service delivery across all utility operations.

CPQ (Configure, Price, Quote) software for energy and utilities is a specialized platform that automates the creation of accurate quotes for complex electrical infrastructure maintenance and power equipment servicing. Energy utility CPQ platforms handle service configurations that include labor, materials, safety protocols, and regulatory compliance requirements specific to power companies. The software ensures quotes meet electrical safety standards while incorporating regional regulations, vendor certifications, and utility asset management requirements. Modern utility CPQ platforms integrate with work-order systems to create seamless workflows from initial maintenance requests through power infrastructure project completion.

Energy sector CPQ software accelerates emergency power outage response by automating quote generation for urgent electrical repairs through pre-configured emergency templates. The power company quoting system automatically applies surge labor rates, expedited shipping costs, and regulatory compliance requirements without manual intervention. Emergency workflows bypass standard approval chains while maintaining audit trails for regulatory compliance. Integration with utility field operations systems enables immediate dispatch with complete material lists and safety protocols, reducing emergency response coordination from hours to minutes for electrical infrastructure service.

Energy utility CPQ platforms manage diverse compliance requirements including electrical safety standards (NESC, IEEE), occupational safety (OSHA), environmental regulations (EPA, Clean Air Act), and industry-specific protocols (NERC reliability standards). The power company software automatically applies voltage-specific safety procedures, environmental protection measures, and regional regulatory requirements based on electrical equipment type and location. Automated documentation generates audit-ready reports, safety protocols, and regulatory filings that satisfy federal agencies (DOE, EPA, FERC), state public utility commissions, and local oversight agencies for power infrastructure operations.

AskCPQ provides conversational AI interfaces that allow electrical technicians to request quotes using natural language rather than navigating complex configuration screens in traditional energy utility software. The system understands electrical industry terminology and automatically pulls relevant data from CRM, FSM, and ERP systems for utility asset management. Traditional power company quoting systems require extensive training and manual data entry, while AskCPQ enables immediate productivity for utility field operations technicians with minimal learning curve. No-code prompt builders allow power companies to customize conversational workflows for recurring electrical infrastructure maintenance scenarios.

Successful power company CPQ implementation requires integration with CRM systems for customer data, ERP platforms for financial and procurement processes, FSM systems for utility asset management and work orders, and inventory management for electrical parts availability. The energy utility platform must connect to regulatory databases for compliance requirements, vendor systems for real-time pricing and inventory, and GIS systems for location-based electrical infrastructure data. API-level integrations ensure bidirectional data flow while maintaining data security and system performance standards required for critical electrical infrastructure operations.

Utility CPQ software addresses skilled electrical technician shortages through guided workflows that help junior technicians perform complex power equipment maintenance procedures safely and accurately. The platform captures institutional knowledge from experienced electrical professionals through systematic documentation of best practices, safety protocols, and troubleshooting procedures for power system maintenance. Automated validation prevents errors that occur when inexperienced technicians attempt complex electrical work without adequate guidance. Training integration provides structured learning paths while performance tracking identifies areas where additional support is needed for utility workforce management.

Energy utility CPQ implementation typically requires 3-6 months depending on integration complexity and organizational readiness for power company operations. The process includes 2-4 weeks for system assessment and planning, 4-8 weeks for configuration and integration development, 2-4 weeks for testing and validation, and 2-4 weeks for training and rollout. Phased deployment approaches allow power companies to implement basic electrical infrastructure functionality quickly while building advanced capabilities over time. Organizations with complex regulatory requirements or extensive system integration needs may require longer implementation periods.